jvandyke

True Classic

new thread from this one

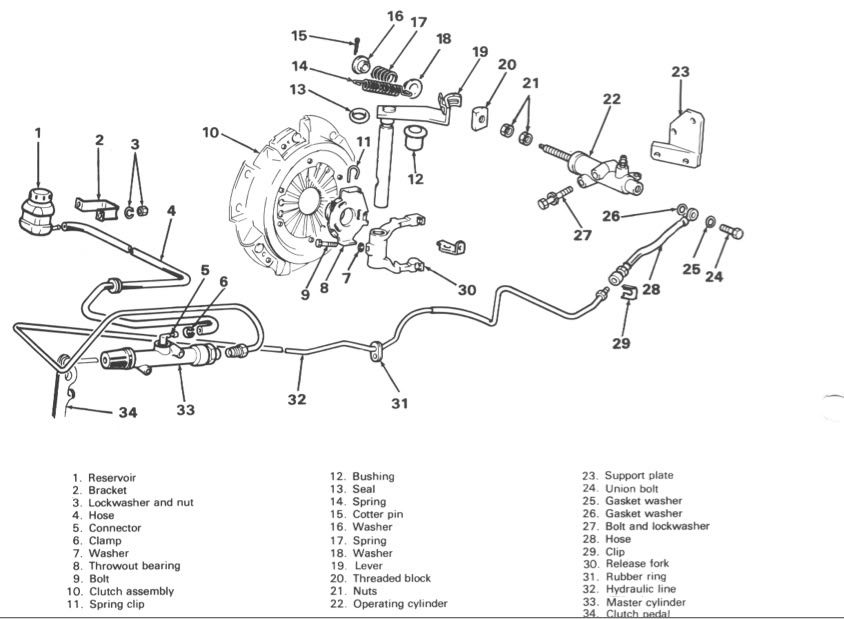

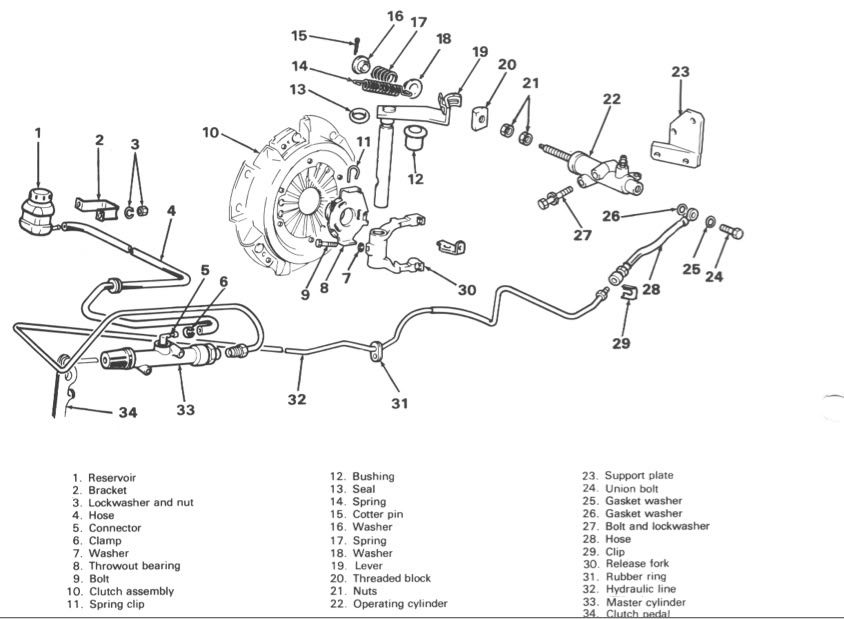

Question: where should the clutch lever (19) be in relation to the slave rod? I can only now get a hard pedal if I artificially hold the rod "in". I've been running with the nut run out to the point where there is nothing left sticking out the other side, no where near enough left for the stock (missing since I got the car) spring and such (16, 17, 18).

I can push the lever towards the engine easily to the limit of the slave's rod leaving it loose and moving even before I start to engage the clutch (I assume). That ain't right? Would that indicate an extremely worn TO bearing? I can move that lever through several inches easily.

Question: where should the clutch lever (19) be in relation to the slave rod? I can only now get a hard pedal if I artificially hold the rod "in". I've been running with the nut run out to the point where there is nothing left sticking out the other side, no where near enough left for the stock (missing since I got the car) spring and such (16, 17, 18).

I can push the lever towards the engine easily to the limit of the slave's rod leaving it loose and moving even before I start to engage the clutch (I assume). That ain't right? Would that indicate an extremely worn TO bearing? I can move that lever through several inches easily.