jvandyke

True Classic

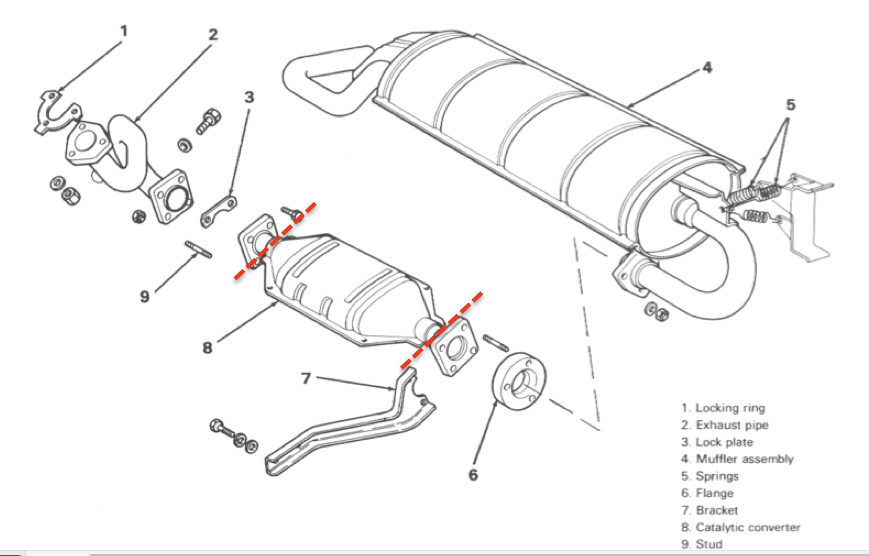

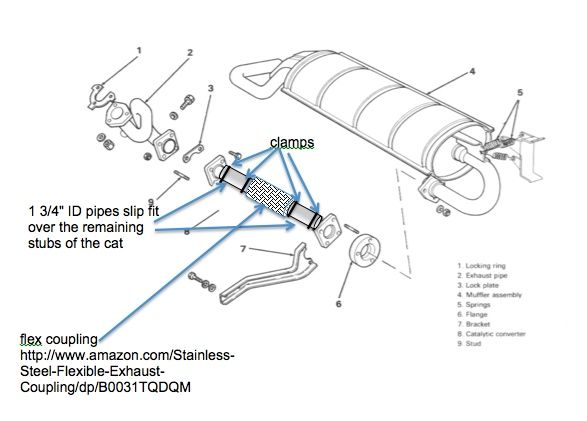

Looking into making a test pipe for an '81 FI exhaust. Replacing the cat with it. Found lots of discussions on it. I've been soaking the flange connections in PB Blaster for a few days but now I wonder if you can't just cut the cat off leaving it all connected, put a pipe in-between and clamp it. I was planning on taking it all apart and having a pipe welded to the cat's flanges but those bolt/nuts/studs look like they won't come off without a huge fight. Apparently, (see link above) one can clamp and get a good fit?