dllubin

Don

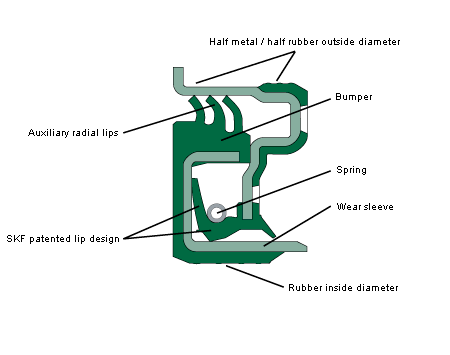

In the process of preparing the engine/drivetrain for installation, I discovered that my left rear wheel bearing was bad. I decided to replace the inner V-ring seal and retrofit an outer V-ring seal (74s did not come with one) when replacing the bearing. The V-ring seal appears to rest against the seal on the side of the wheel bearing when installed. It appears that it was designed to protect the interface between the inner race and the wheel bearing seal. My new wheel bearing arrived and the seals on it are attached to the outer race and the seal interface is at the inner race. I could see how the V-ring seal adds protection to that interface.

I decided to replace the RR inner V-ring seal at the same time since it is pretty easy to get to unlike the outer seal which requires pressing out the hub (That means replacing the bearing and this one was low mileage, being replaced shortly before the old engine blew). After I removed the axle, I took a look at the bearing and found that the seals on it are attached to the inner race and the seal interface is at the outer race. The V-ring seal does not reach that interface so I cannot see how it would add much protection to this type of bearing. On the plus side, since both seals are rotating together, there should not be any wear.

I'm not sure what the prevailing trend is in X1/9 wheel bearing seal design, but in the future I will look for ones that have the seal attached to the outer race so that the V-ring seal has a chance of doing it's job.

For reference, the new bearing with the seal attached to the outer race is an OMCAR 007A11700. The existing bearing with the seal attached to the inner race is a GREEN 4339308.

I decided to replace the RR inner V-ring seal at the same time since it is pretty easy to get to unlike the outer seal which requires pressing out the hub (That means replacing the bearing and this one was low mileage, being replaced shortly before the old engine blew). After I removed the axle, I took a look at the bearing and found that the seals on it are attached to the inner race and the seal interface is at the outer race. The V-ring seal does not reach that interface so I cannot see how it would add much protection to this type of bearing. On the plus side, since both seals are rotating together, there should not be any wear.

I'm not sure what the prevailing trend is in X1/9 wheel bearing seal design, but in the future I will look for ones that have the seal attached to the outer race so that the V-ring seal has a chance of doing it's job.

For reference, the new bearing with the seal attached to the outer race is an OMCAR 007A11700. The existing bearing with the seal attached to the inner race is a GREEN 4339308.