The latest update on my quest to stiffen the exxe chassis without making it look like a race car (i.e., rollbar etc). Everyone has seen strut tower braces where you bolt it up to the strut tower studs to transfer the high-load (outside wheel) strut tower pull to the less loaded inside tower. Since I'm do a full body restoration, I figured I should take advantage of it and go overboard again. There are some considerations I needed to deal with since I was going for a stock look and function:

- I still want to be able to use the frunk for luggage as well as put the targa top there without modifications

- Need to be able to service the battery

- I wanted to tie the whole thing into the center tunnel as it is now much stronger

- try to be as light as possible while still being strong

Here's what I came up with:

the red bits are welds, the yellow bars are threaded aluminum suspension tubes

(2 10" ones for the lowers and

one 23" one for the top). these are left and right threaded to adjust the distance and tighten for tension preload. I picked up some jam nuts to keep it steady and provide the minimal compression that might occur. Here it's mocked up:

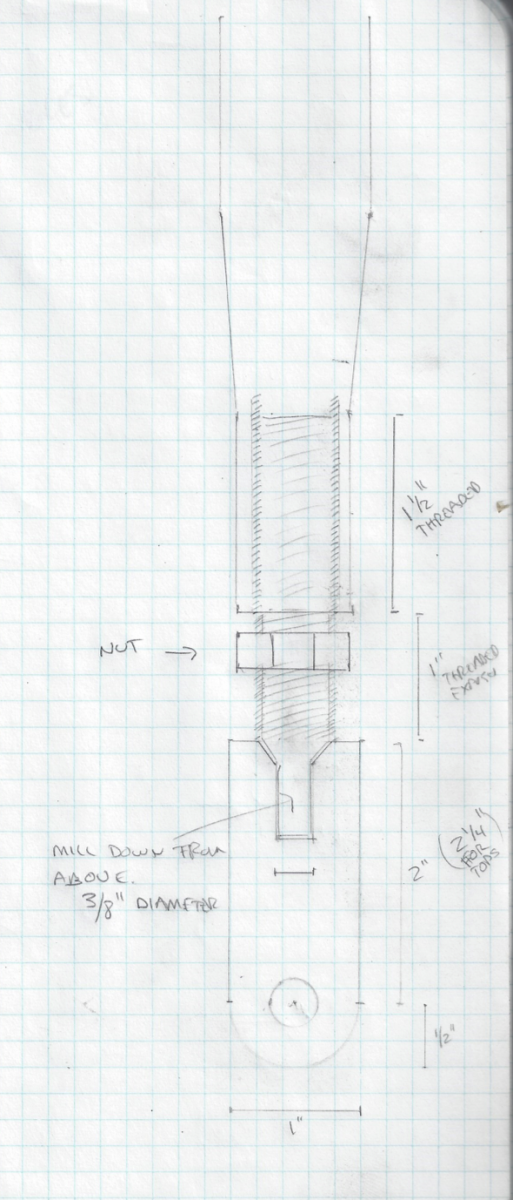

As much as I would prefer to get metric threaded bars, that was gonna be hard to come buy and much more expensive, so these are 5/8"-18 threads. I needed to get both right-hand AND left hand threaded rod or bolts or something to fabricate the mount to the body, but I couldn't really find any. One could get heim-joint connections and go that route, but that seemed clunky somehow to me and I wanted something thinner that would just to the job of transferring tension and compression load, so I designed the custom part.

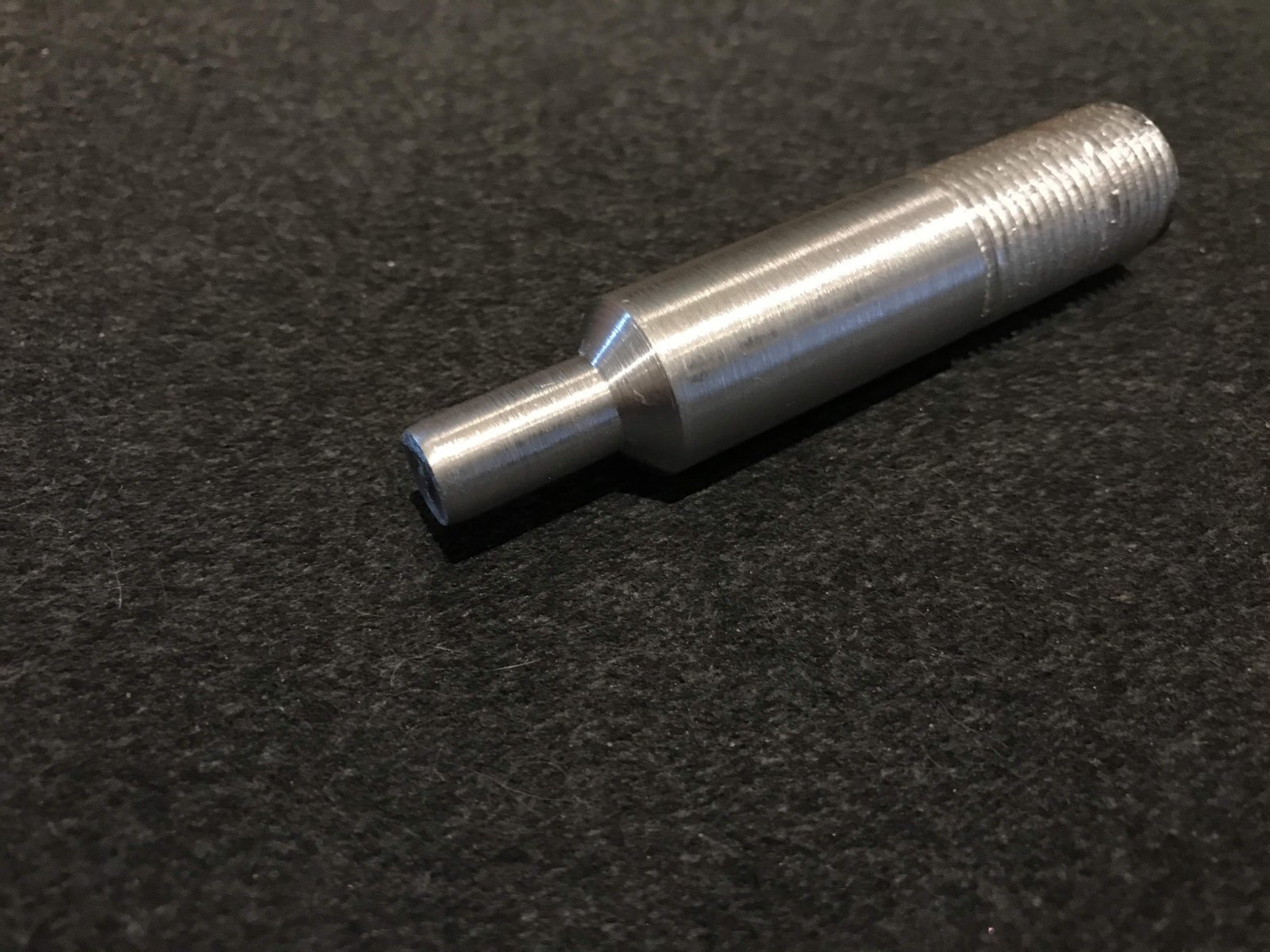

it's basically a stainless threaded bar that tapers down and is TIG'd to a 1"x2" tab of 1/8" stainless. My neighbor a couple houses down has two metal lathes and I tried to get him to build it for me, but... anyways - I ended up just buying his small one. Plan is to build my own - not that I know how to use a lathe or anything, but it's never too late to learn. How hard can it be, right? Anyways, that's why I picked up the lathe. Turns out cutting threads is pretty hard and involved. My first attempt (on aluminum for practice) isn't good, but it sorta shows what I'm gonna try to do.

On the towers, I cut out some 14g steel to shape and attached to the towers down a bit point below where the targa goes in and in front of the battery box. It would be stronger and lighter if one could simple use the top plane of the towers but that's right where the targa goes. Anyways, cut and weld and cleaned and stitched the layered seams (I'll need to ensure I get good primer and seam sealer there to protect that area once painted).

The tabs are all welded and lined up allowing the two lowers to bolt in front and the upper brace rearward - that's why I ran the fishing wire, just to verify.

As my plan above shows, I wanted to also tie into the center tunnel and the ledge in the center looked like a great place to do it. I'll be creating a strong triangle along with the strut brace that will assist the front firewall in torsional strength. The one issue is that the steering rack channel is under it, so no real way of tying it directly in. After investigation, I saw that the steering rack is bolted to the front firewall right where the tunnel connects (and it is a good thick piece of flat steel already welded at the factory). To support the added brace and tie into the tunnel, I fabbed and welded in some small pieces that should do the trick. Here's a couple of photos taken in the steering tunnel:

Should be pretty strong. Yeah, it's total overkill but I only get one chance at these mods before it goes to paint, so I'm fine with it.

Also, this is a 1976, so the washer tank is in the drivers side headlight pod. I'm not running a stock exxe transmission, so no need to worry about the speedometer cable, however - I think this particular mod would work and fit fine on a later car with the larger washer tank as well as clear the speedo cable bits.