Hey guys I've had my X for about one and a hafe years and its the first manual trans that I've had that when I put in gear the gear shifter will move out of its position but it still stays in gear I checked gear linkage replaced the linkage bolt and lined everything up bit still no luck I hope some one can help

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stick shifter play

- Thread starter Tino

- Start date

dragonsgate

True Classic

Floppy shifter is not unusual. Does it engage the gears easily? Check the rubber on the lollypop for tearing and make sure the connecting bolts are secured properly.

johnph

True Classic

Also, check the transmission crossmember for cracks at the center. While it is out, verify that the transmission mount is not worn out and the nuts and bolts are secure. The crossmember must be properly secure via the 4 bolts to the unit body. If it drops down, shift action becomes sloppy.

kmead

Old enough to know better

Are you saying you can actually move the shifter to another gear position or that there is some ‘slop’ in that it can move forward or back a small amount or to the left or right?Hey guys I've had my X for about one and a hafe years and its the first manual trans that I've had that when I put in gear the gear shifter will move out of its position but it still stays in gear I checked gear linkage replaced the linkage bolt and lined everything up bit still no luck I hope some one can help

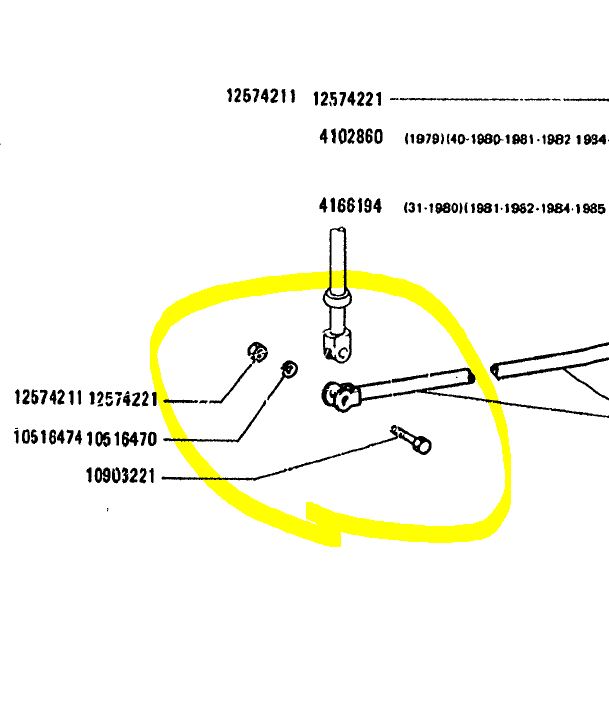

The link between the shifter shaft after it comes out of the tunnel into the engine bay can become delaminated over time and allow movement, it is common to run a through bolt to clamp the assembly together.

The bolt and nut that connect the flex link to the transmission can become loose or in a few cases we have seen the shifter shaft into the transmission get damaged and allow extraneous motion.

It is also possible to have the shifter assembly in the passenger compartment itself wear so working your way through the various parts would be the right way to figure out the problem.

Do you have trouble choosing a gear?

Dr.Jeff

True Classic

@carl has made some good posts about this. One item he notes is the boot at the rear end of the tunnel, locating the long shift rod. Look for some of his threads to see if there is anything that might help. However there will always be some "slop" in the X's shifter. It is the design of the system that allows it even when everything is good. So you can't compare it to other cars.

carl

True Classic

It's no Miata. As noted by the doctor, there is plenty of play in the X shifter, the end of my shifter seems to move a lot even when in gear. If you need comparisons I can go out to mine tomorrow and measure any side to side and fore aft motion while the lever is in a gear. Do you have any problem finding gears as you drive?

Yes if you can check that would be great I appreciate everyone's help . And all gears do go in but not as smooth as I would like. In the fall I did change the trans fluid to redline mtl only drove it once before putting it away for the winter , hopefully this summer when I drive it more it might help

carl

True Classic

I checked the shifter on my five speed X. Measured at the base of the threaded portion for the shiftball and in 1st gear.

Side to side movement is about 1/2" of free play, about 2" if you pull on it left and right. Front to back movement is about 1/2". If you pull back too hard you shift out of gear.

For comparison, my 124 spider has about 1/4" movement in side to side and for and aft.

Side to side movement is about 1/2" of free play, about 2" if you pull on it left and right. Front to back movement is about 1/2". If you pull back too hard you shift out of gear.

For comparison, my 124 spider has about 1/4" movement in side to side and for and aft.

Dan Sarandrea (Phila)

Waitin' On Parts...

There are three pivot points and one sort-of-support point that you can check for looseness and wear. In all three cases you can make some adjustments.

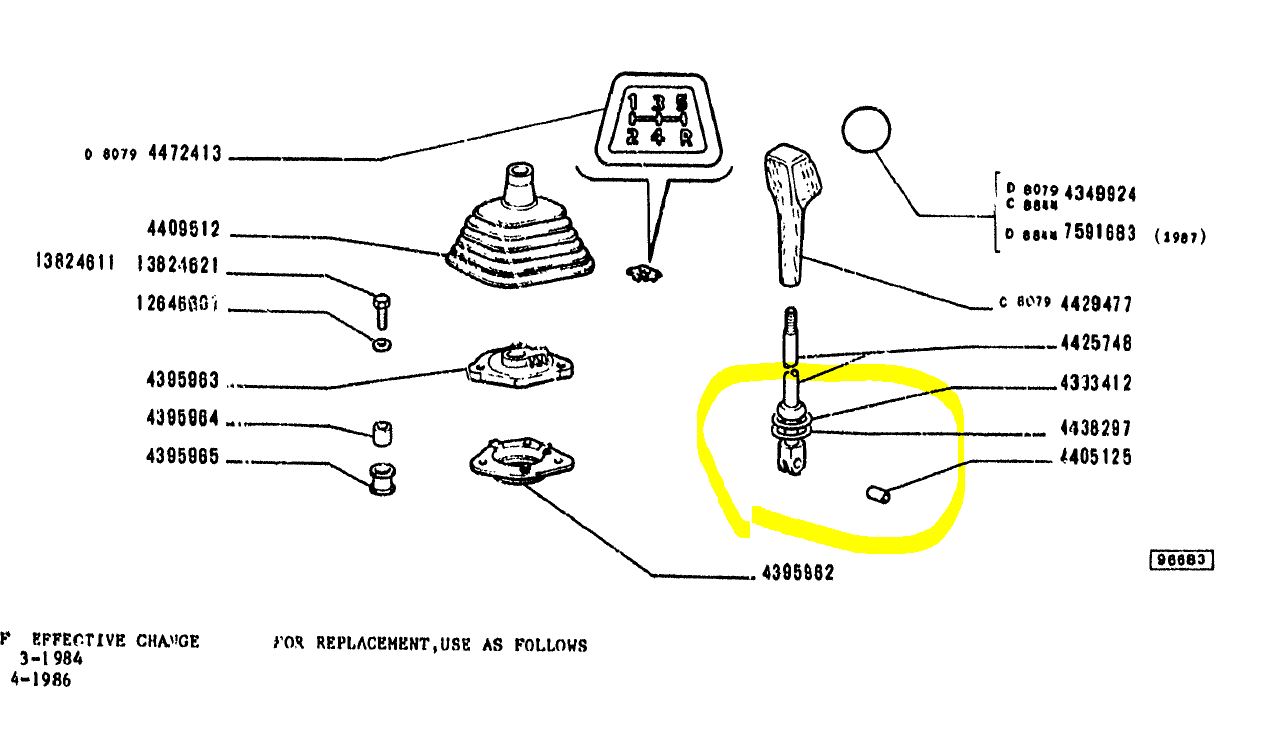

1. The plastic pivot ball on the shift lever itself. This is sandwiched between the halves of the shift lever mount that fastens to the center tunnel with three capscrews. Disassemble this and check that the black rubber collar and white plastic collar inside are intact.

2. The clevis at the base of the shift lever. Check for loose nut and bolt, or wallowed-out holes in the shift lever and/or shift rod.

3. Lollipop--already covered by other posters.

4. The boot that seals the opening at the back of the center tunnel through which the shift rod protrudes does provide a minor level of control and support, as described by Dr. Jeff above. Check to see if the boot is missing, torn, or otherwise deteriorated.

1. The plastic pivot ball on the shift lever itself. This is sandwiched between the halves of the shift lever mount that fastens to the center tunnel with three capscrews. Disassemble this and check that the black rubber collar and white plastic collar inside are intact.

2. The clevis at the base of the shift lever. Check for loose nut and bolt, or wallowed-out holes in the shift lever and/or shift rod.

3. Lollipop--already covered by other posters.

4. The boot that seals the opening at the back of the center tunnel through which the shift rod protrudes does provide a minor level of control and support, as described by Dr. Jeff above. Check to see if the boot is missing, torn, or otherwise deteriorated.

Dr.Jeff

True Classic

Dan, I'm curious if you have replaced any of those three points with new parts (Eurosport sells them)? I'd like to know if it helped the play much. I ask because one member once stated he replaced everything possible and it did not improve things. However that might have been a isolated case, so I'm interested to hear about more examples. ThanksThere are three pivot points and one sort-of-support point that you can check for looseness and wear. In all three cases you can make some adjustments.

1. The plastic pivot ball on the shift lever itself. This is sandwiched between the halves of the shift lever mount that fastens to the center tunnel with three capscrews. Disassemble this and check that the black rubber collar and white plastic collar inside are intact.

View attachment 58352

2. The clevis at the base of the shift lever. Check for loose nut and bolt, or wallowed-out holes in the shift lever and/or shift rod.

View attachment 58353

3. Lollipop--already covered by other posters.

4. The boot that seals the opening at the back of the center tunnel through which the shift rod protrudes does provide a minor level of control and support, as described by Dr. Jeff above. Check to see if the boot is missing, torn, or otherwise deteriorated.

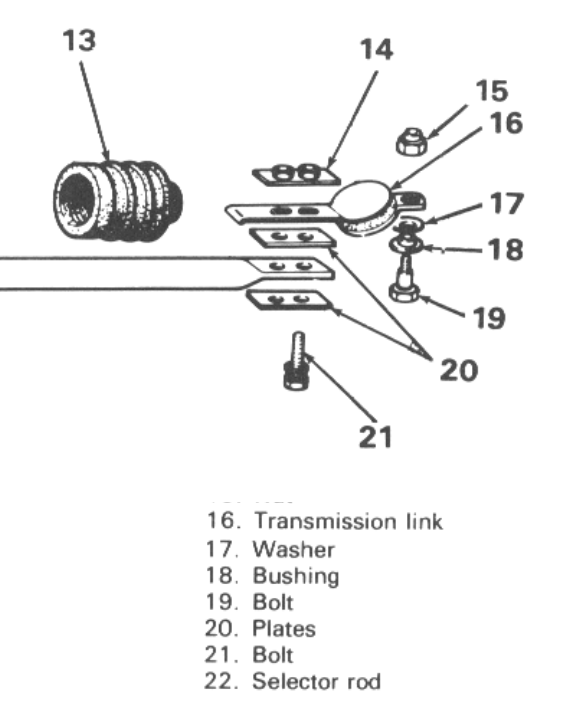

I believe I check all but I'm very curious about the transmission lincage lollipop ,all bolts are aligned properly I'm wondering how the bolt with the wavy washer and bushing should be tighten if overly tighten or not to tight and if the lincage should move a bit when shifting gears at the bolt location would it make a smother shift I want to thank you all for all the help

ng_randolph

Bjorn H

Shoulder bolt (19) and nut (15) should be torqued down, not left loose. The FSM gives a torque value, but this value is wrong (it is assuming the bolt is M8; it isn't). 9.5 Nm (~7 lbf ft) would be a reasonable value. Bolt (19), bushing (18), and nut (15) should all be firmly mounted to the shift shaft from the transmission. The only movement should be between the bushing (18) and the Transmission link (16), "lollipop", pressed together by wavy washer (17).

Dr.Jeff

True Classic

@carl has some good feedback on this in his prior posts about the joint.

The shouldered bolt and wavy washer assembly are intended to act a little like a "universal joint", so it can pivot as the shaft rotates and slides fore/aft. That's also why there is a bend in the lollipop linkage to put it at an angle, allowing multi-axis movement. Therefore the joint at the bolt's shank should not be too tight (hence the stepped bolt). The wavy washer allows slippage and the lock-nut maintains the setting. However it requires re-adjustment over time. The whole thing wears, elongates, and gets sloppy. Ideally it should be something more solid like this:

The shouldered bolt and wavy washer assembly are intended to act a little like a "universal joint", so it can pivot as the shaft rotates and slides fore/aft. That's also why there is a bend in the lollipop linkage to put it at an angle, allowing multi-axis movement. Therefore the joint at the bolt's shank should not be too tight (hence the stepped bolt). The wavy washer allows slippage and the lock-nut maintains the setting. However it requires re-adjustment over time. The whole thing wears, elongates, and gets sloppy. Ideally it should be something more solid like this:

Dr.Jeff

True Classic

Bjorn, I wonder if the FEM's data seems odd due to this being a shouldered bolt rather than a regular (straight shank) bolt? Or they may have deliberately used a non-standard torque value to compensate for the (poor) design and function? However the whole thing wears so much that no torque value will remain for too long.The FSM gives a torque value, but this value is wrong (it is assuming the bolt is M8; it isn't). 9.5 Nm would be a reasonable value.

Dan Sarandrea (Phila)

Waitin' On Parts...

I replaced the rubber ring in the shifter ball pivot (after cleaning and lubing with a silicone based grease so as not to affect the rubber ring), and I also squeezed the "fork" at the end of the shift rod (or used some washers or shim stock, it was a few years ago) to close up the tolerances. I think it improved feel and function somewhat.Dan, I'm curious if you have replaced any of those three points with new parts (Eurosport sells them)? I'd like to know if it helped the play much. I ask because one member once stated he replaced everything possible and it did not improve things. However that might have been a isolated case, so I'm interested to hear about more examples. Thanks

I've always maintained that if someone could come up with a Ferrari-like shift gate for our cars, it would be a big seller.

Last edited:

carl

True Classic

All side to side motion of the linkage should come only from that wavy washer bolted up connection at the transmission/lollipop connection. Take a few degrees of rotational movement and then multiply that by the length of the gear lever and you can generate some appreciable side to side motion at the end of the gear lever. I think that wavy washer shouldered bolt is too small and subject to stretch and the lock nut backs off. Just my guess. Ideally you want zero rotational free play at the transmission/lollipop joint but free rotational movement. That's a hard point to reach on a simple bolted joint.

The people we have not heard from on this are the racers where crisp accurate shifts are required.

The people we have not heard from on this are the racers where crisp accurate shifts are required.