RyanG

True Classic

I’m looking for some advice here as I’m not sure what the best path is. I’ve owned my ‘82 FI x1/9 for about 2 years. It’s essentially stock. The engine runs fairly well and when I first picked it up I went through and replaced hoses, gaskets, timing belt, etc. Like a lot of you I’d like a bit more power.

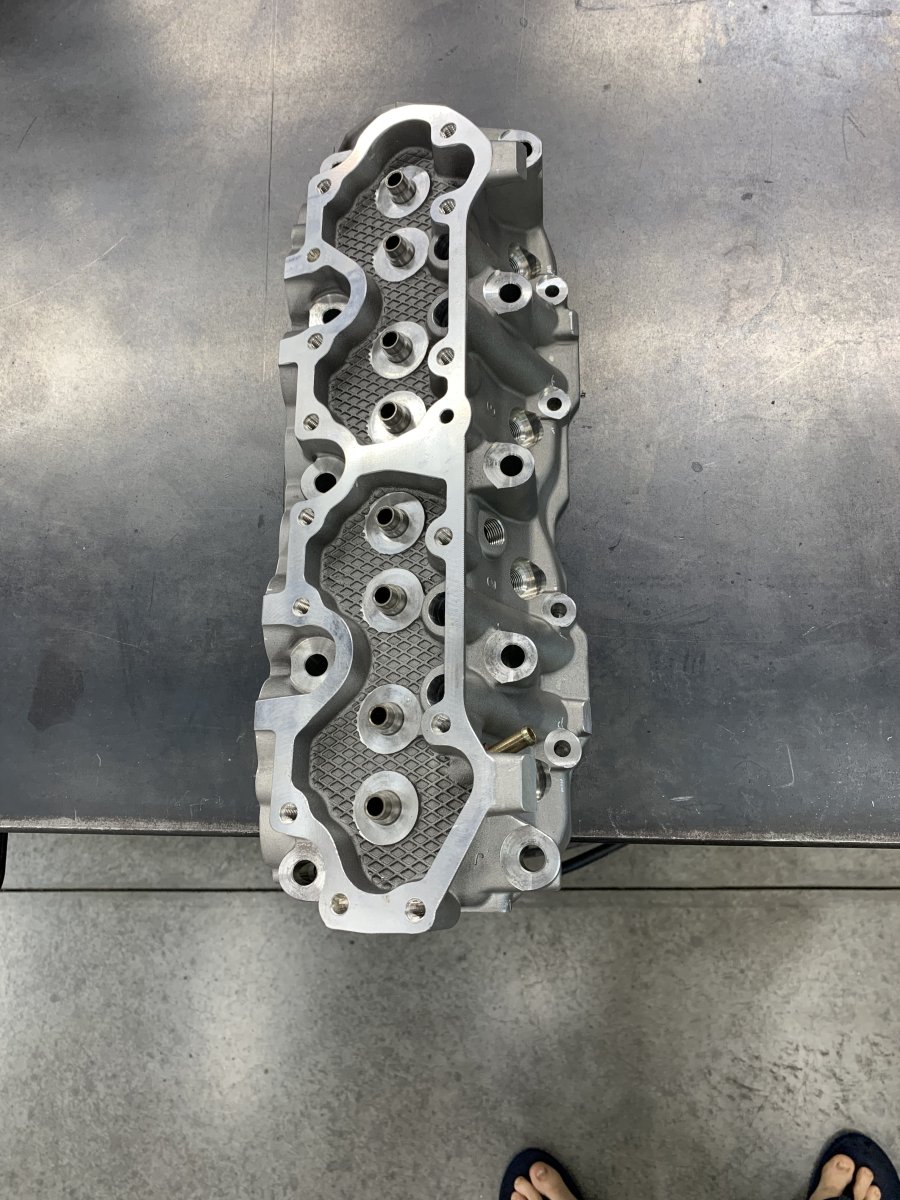

I’ve picked up what I believe to be a NOS Chinese big valve (Tipo?) head. I’d like to use this to take advantage of larger intake valves and higher compression.

At this point I’d keep the stock FI system, add a performance cam (suggestions welcome, I’d like to find one that isn’t a regrind and doesn’t require milling the cam box), either header exhaust or a Fiat cast 4-2 exhaust manifold, and lighten the flywheel.

This all seems pretty standard stuff. However I have some questions.

1. The exhaust valves on the Chinese head are smaller than the stock FI head. Is it worth having the exhaust valve seats replaced with the larger (33mm?) size.

2. Will the stock FI system work ok with this modified head, higher compression, performance cam (within reason).

3. I also have a spare block that I considered boring to 87mm and getting higher compression pistons. Again- will this make much difference for power with the modifications to the head and will the stock FI system be able to cope?

I’ve toyed with the idea of a full build with itbs, microsquirt system and bored block but I’m afraid of going down a path where I will never reach the end. I appreciate any advice.

I’ve picked up what I believe to be a NOS Chinese big valve (Tipo?) head. I’d like to use this to take advantage of larger intake valves and higher compression.

At this point I’d keep the stock FI system, add a performance cam (suggestions welcome, I’d like to find one that isn’t a regrind and doesn’t require milling the cam box), either header exhaust or a Fiat cast 4-2 exhaust manifold, and lighten the flywheel.

This all seems pretty standard stuff. However I have some questions.

1. The exhaust valves on the Chinese head are smaller than the stock FI head. Is it worth having the exhaust valve seats replaced with the larger (33mm?) size.

2. Will the stock FI system work ok with this modified head, higher compression, performance cam (within reason).

3. I also have a spare block that I considered boring to 87mm and getting higher compression pistons. Again- will this make much difference for power with the modifications to the head and will the stock FI system be able to cope?

I’ve toyed with the idea of a full build with itbs, microsquirt system and bored block but I’m afraid of going down a path where I will never reach the end. I appreciate any advice.