Inner Fender Fabrication

The inner fender features a large oval embossed area where the bumper brackets attach. A doubler with dimples nests into the back side as well. I built a pressing tool to create the oval form. Originally, I thought the angle of the sides of the dimple were a 35-degree angle (it was difficult to measure) so I machined the form with the head of the Bridgeport tilted and then sanded the facets smooth. It ended up needing a 45-degree angle, which meant I could have machined it in a flat orientation (with a 45-degree end mill) and done the ends on the rotary table. Oh well.

For the female portion of the form I machined steps and then blended them by sanding. Again, if I had known it was 45-degrees life would have been easier...

The two halves of the form were aligned to the panel and to each other with bolts, then popped in a cheap hydraulic press.

The pressing of the test panel showed significant drawing of material from around the dimple, which resulted in some waves that I wouldn’t be able to remove. At this point I opted to trim the dimple out and then weld it into the panel.

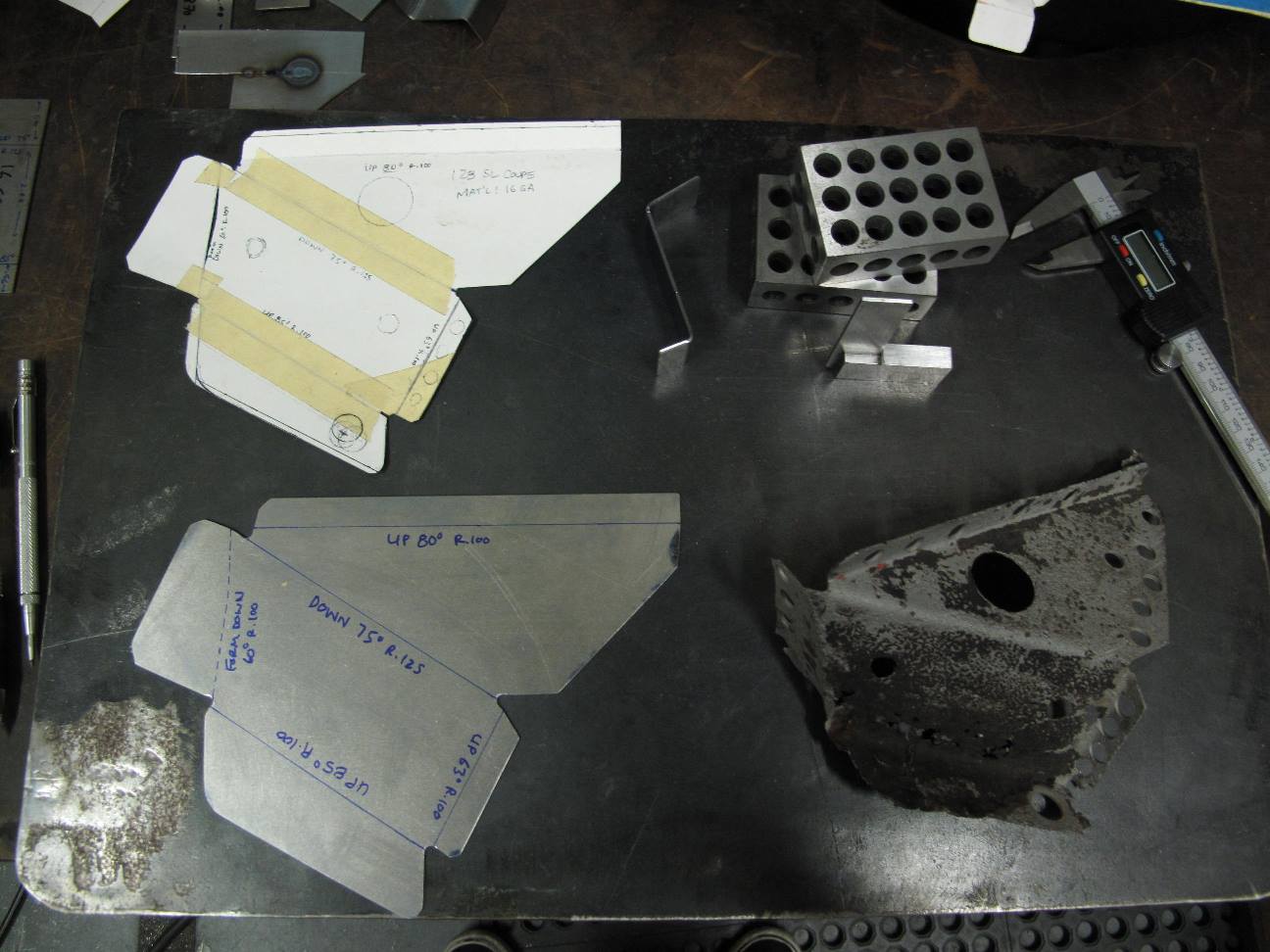

Oh yeah, the template looked like this:

Last steps were to add holes for plug welding and run the bottom edge through the bead roller to create the joggled flange.

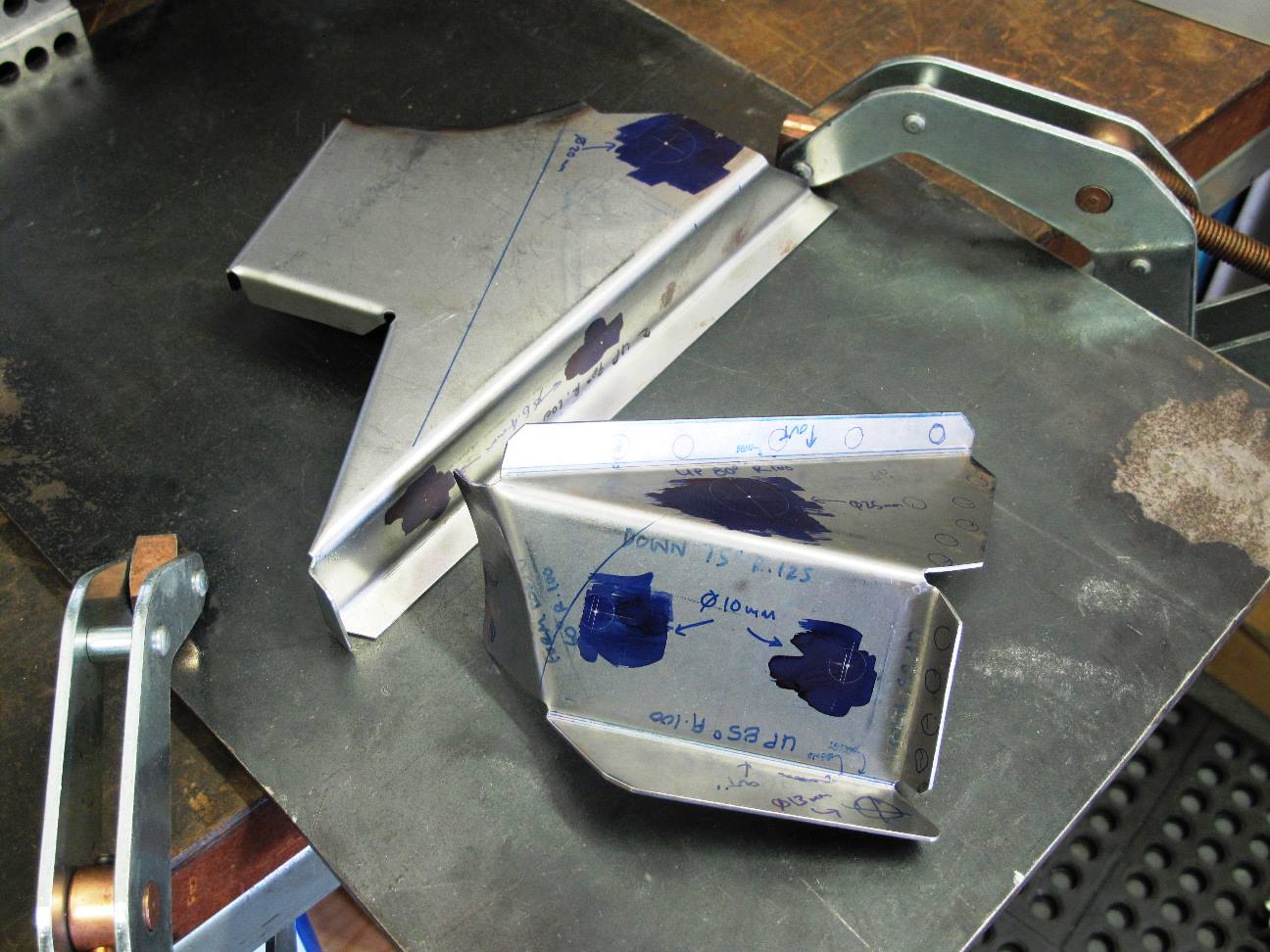

Now on to my best effort at creating the portion of the inner fender behind the battery tray. It had some compound curves that made things interesting. I did my best to derive the flat shapes and straight bends, then filled in the rest with patchwork.

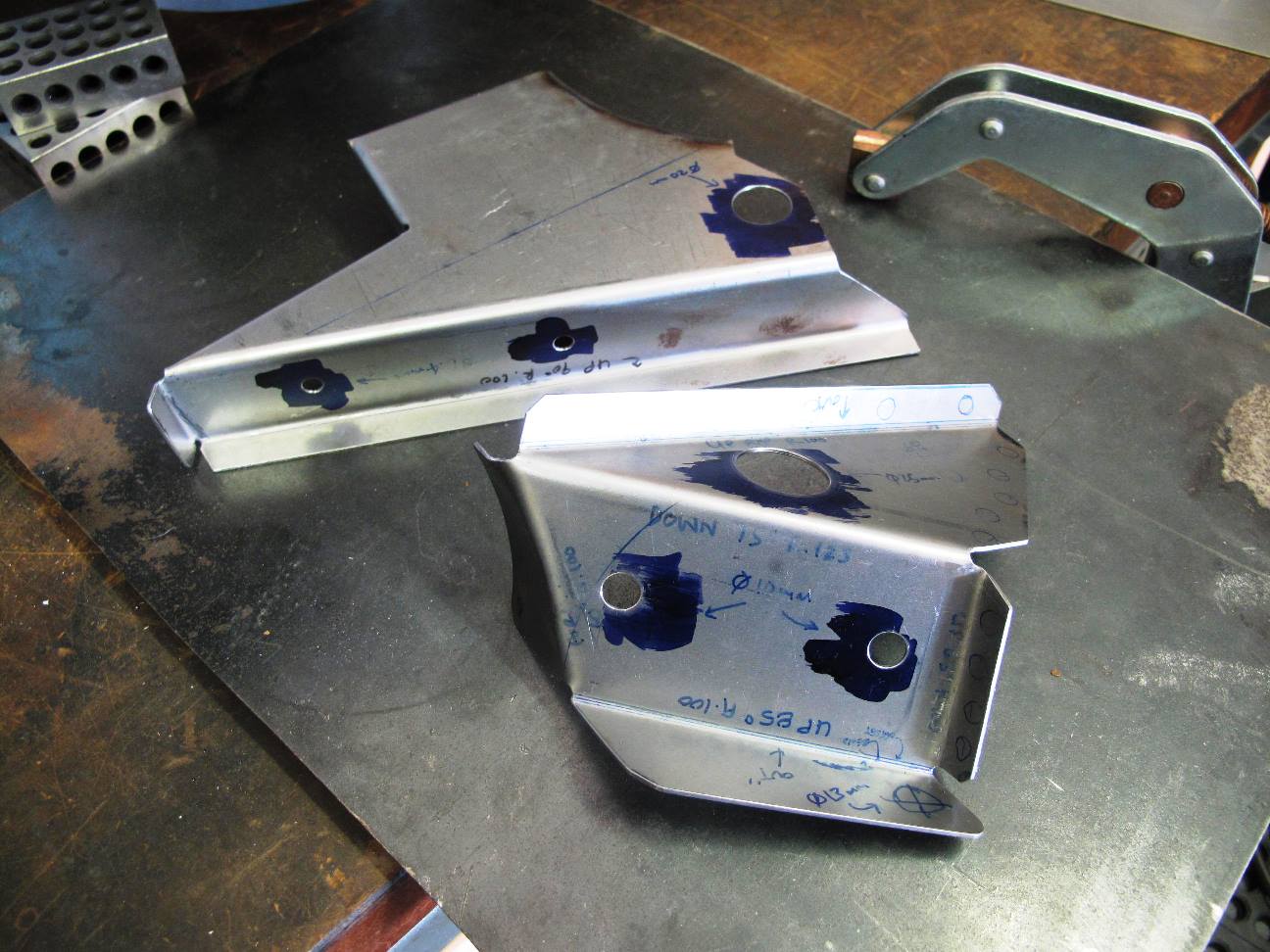

The large radius bends were formed by making small step bends in the finger brake and the size checked with a template.

Forming the 10 degree bend in the middle:

Checking fit:

We're getting closer to welding! But one more big part remains.