Frank L. Di Gioia

True Classic

Having been away from Fiats for a little over a decade I came home to find a 1967 Fiat 850 SCCA road race veteran in my garage. It had been sitting in the desert for about 12 years semi-covered with the usual "spare parts." Since it wouldn't leave I told my wife that if I got it running I could then drive it away or sell it for big bucks. I don't think she bought it but I reminded of her having stated she could make money on show horses. That was about 6 months ago and the marriage counselor says things are progressing toward an understanding. That covered, the car was a little worse for wear than originally thought. Seeing a rust free battery tray caused me to not examine the floors very well. Mistake. Also it seems the Parumph Nevada race course has great sand filled run off areas backed up by 10" diameter rocks. The Spider was capable of avoiding the sand but not the rocks. The car was converted to racing in 1968 so actually had few miles on it. I followed the standard route of pulling everything off and cleaning, painting, and bolting back on. It's at the stage of clean underside, brakes rebuilt, everything stripped replaced. Goal is a track day car, street legal (counting on Dr. Jeff here) with vintage plates.

It's not destined to be a trailer Queen. The goal is every nut, bolt, adjustment will be clean, functioning, correctly installed. Best thing is it came with BOTH COVERED HEADLIGHT LENS!!!

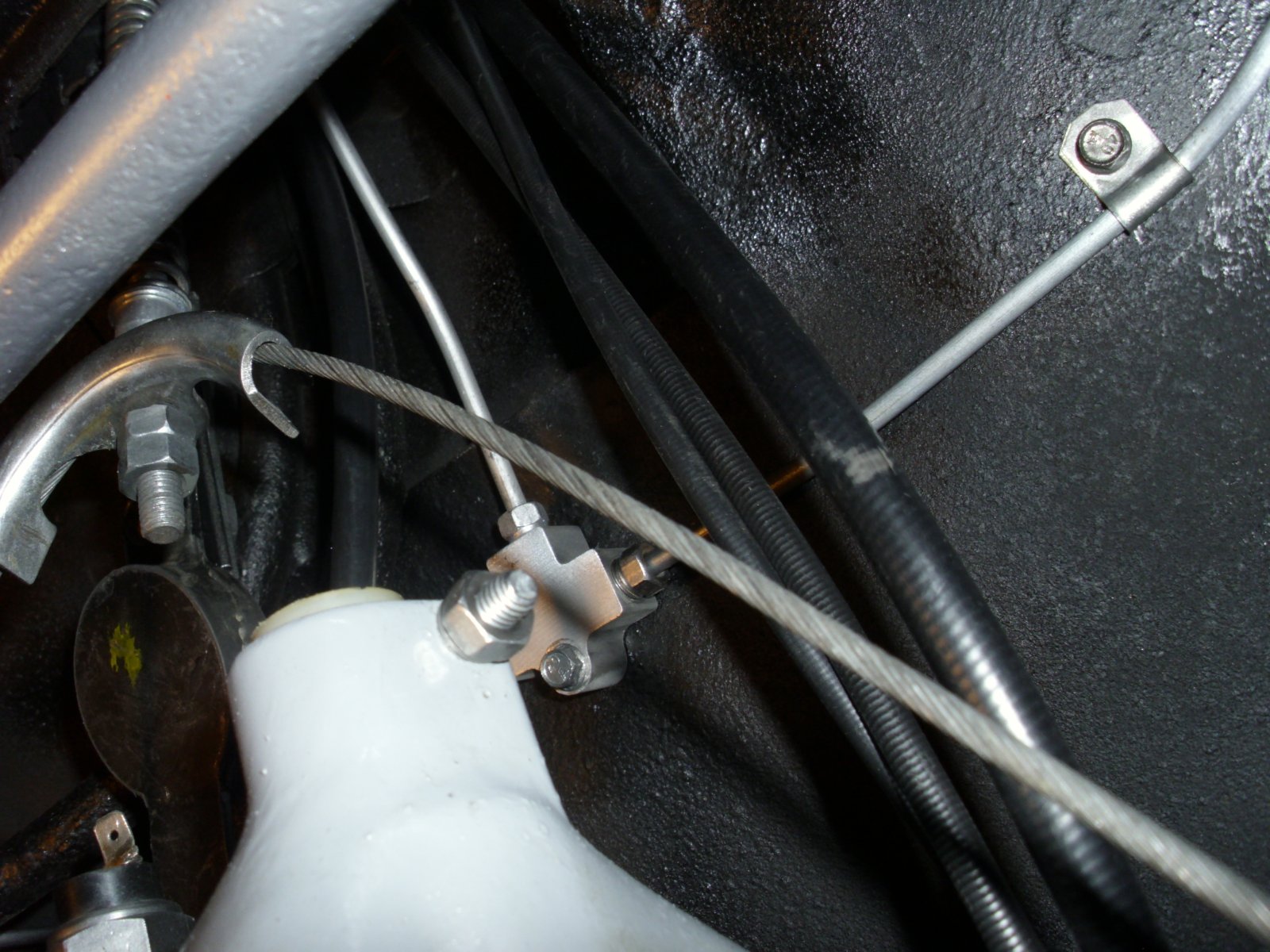

All I have to do is remove the cute "moon eyes" painted on them.... The A112 valve cover/intake and just about everything else I've sourced as the original owner wasn't too oriented toward "looks" as to driving and having fun. Basis tool kit was hack saw, pop gun (over 100 holes in engine bay needing filling) and bailing wire instead of cotter pins. Oh, I forgot the duct tape.

It's not destined to be a trailer Queen. The goal is every nut, bolt, adjustment will be clean, functioning, correctly installed. Best thing is it came with BOTH COVERED HEADLIGHT LENS!!!

All I have to do is remove the cute "moon eyes" painted on them.... The A112 valve cover/intake and just about everything else I've sourced as the original owner wasn't too oriented toward "looks" as to driving and having fun. Basis tool kit was hack saw, pop gun (over 100 holes in engine bay needing filling) and bailing wire instead of cotter pins. Oh, I forgot the duct tape.