You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1976 Scorpion; Gold

- Thread starter icr

- Start date

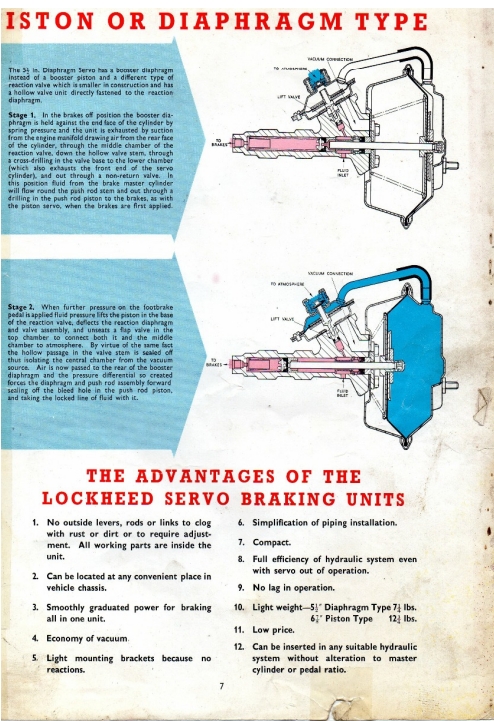

I'll probably be getting a new manufacture replica booster.

The issue with the brakes not releasing on demand is from the same piston that is frozen in my unit. You can see in post #137 the spring that releases the brakes (by pressing the pistion back) is rather whimpy. Any unnecessary friction in the bore of the piston will cause a delay in the release of the brakes.

The issue with the brakes not releasing on demand is from the same piston that is frozen in my unit. You can see in post #137 the spring that releases the brakes (by pressing the pistion back) is rather whimpy. Any unnecessary friction in the bore of the piston will cause a delay in the release of the brakes.

I got some wheel cribs and was able to get the brake booster out.

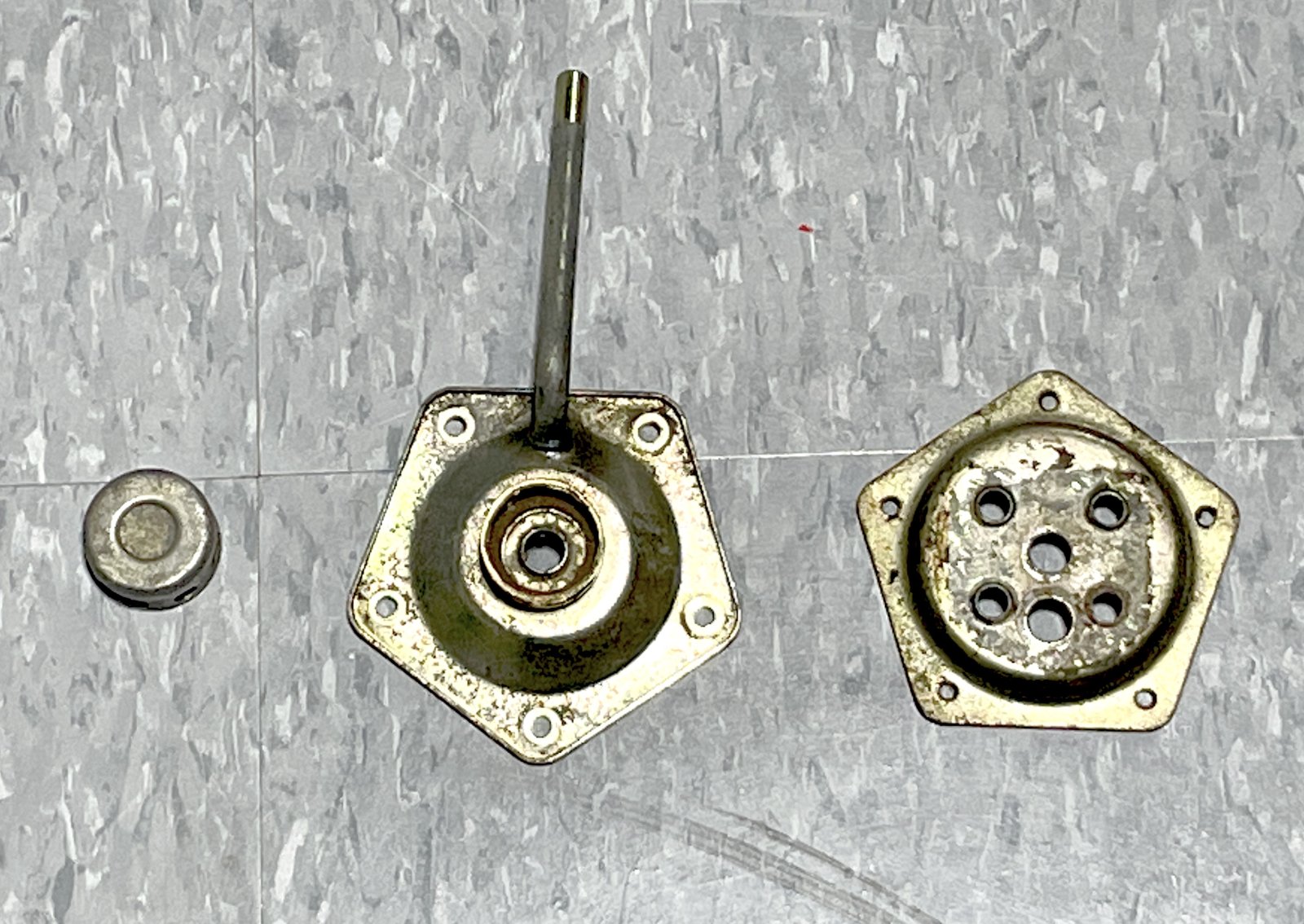

With some work I got the frozen piston out. I may rebuild this unit, as a spare and order a new unit.

I need to measure the flange nut threads to confirm it is 3/8-24, as replacemment boosters are seen with 10x1.0 and 10x1.25 depending on the intended application.

With some work I got the frozen piston out. I may rebuild this unit, as a spare and order a new unit.

I need to measure the flange nut threads to confirm it is 3/8-24, as replacemment boosters are seen with 10x1.0 and 10x1.25 depending on the intended application.

After much searching I located both a plating shop and an appropriate rebuild kit. Rebuild kit from UK and plating shop 3 hours away.

Since I had never used that plating shop before, I drove 3 hours to deliver the parts and talk to the owner. Seems like a good place with which to do business. Family owned and operated since the 1970s and willing to do small jobs at a reasonable price.

These are the pieces I left with the electroplater.

Since I had never used that plating shop before, I drove 3 hours to deliver the parts and talk to the owner. Seems like a good place with which to do business. Family owned and operated since the 1970s and willing to do small jobs at a reasonable price.

These are the pieces I left with the electroplater.

A Scorpion owner on FerrariChat indicated Power Brake Exchange in San Jose, Ca. rebuilt their booster and posted the picture of it below. I did not want to send mine to CA for a $600 re-plating, plus mine is already disassembled, just needs the rubber parts and re-assembly. My plater quoted $80.

NigelProdrive

True Classic

Could be good time for wheel stud conversion. Aluminum wheel spacer instead of the heavy cast iron ones.

I can say in all my years of car ownership I have never owned a car with studs. What is the advantage?Could be good time for wheel stud conversion. Aluminum wheel spacer instead of the heavy cast iron ones.

RJ80

True Classic

Easier wheel changes, for one. I used the MWB studs on my Scorpion and a prior 124 Spider and they work great.I can say in all my years of car ownership I have never owned a car with studs. What is the advantage?

NigelProdrive

True Classic

Wheel changes not having to sit there trying to line up holes.I can say in all my years of car ownership I have never owned a car with studs. What is the advantage?

Not having to have 2 sets of hardware to use both your wheels and stands. Just slide stand onto studs and use same lug nuts that mount wheels.

No need for the alignment bolts that fasten factory wheel spacer to hub.

New lugnuts > resto bolts