You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1976 Scorpion; Gold

- Thread starter icr

- Start date

NigelProdrive

True Classic

The original bowtie wheels came painted. The original alloy is near the same color the paint just shiny when stripped. Its almost better to strip them and clear coat and never have to worry about the silver paint chipping, bubbling or being scratched.Wheels are off, ready to go to the wheel restoration shop.

View attachment 69652

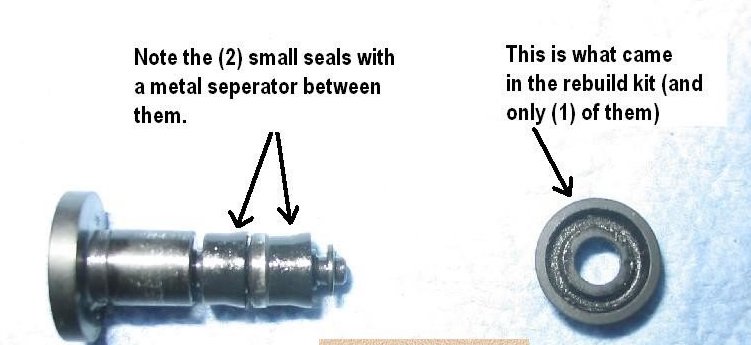

As predicted, the Bonaldi-Alfa booster rebuild kit did not come with the tiny seals for the little piston. In my case, the originals were still in good shape.

Externally the Alfa and Lancia/Lamborghini Bonaldi boosters are similar except for the number of mounting studs. Internally the differences are as listed below. So the Alfa style rebuild kit has everything except those two small seals.

Bonalid-Alfa = two mounting studs, 3/8 -24 flare nut threads and single seal on small piston. [Available new or reproduction]

Bonaldi-Lancia/Lamborghini = three mounting studs, 10mm 1.25 flare nut threads and two seals on small piston. [Not available]

Externally the Alfa and Lancia/Lamborghini Bonaldi boosters are similar except for the number of mounting studs. Internally the differences are as listed below. So the Alfa style rebuild kit has everything except those two small seals.

Bonalid-Alfa = two mounting studs, 3/8 -24 flare nut threads and single seal on small piston. [Available new or reproduction]

Bonaldi-Lancia/Lamborghini = three mounting studs, 10mm 1.25 flare nut threads and two seals on small piston. [Not available]

Last edited:

The original finish on these parts was not too bad, but I needed something to give to the plater for the first time to see if he was any good. Knowing if it came out bad it was pretty hidden. I'm very impressed so I gave him another box of items. The screw, nut and washer for the tensioning ring were also a test. The did not lose them and they came out perfect.

I gave him the 16 wheel bolts for Black Zinc and the 4 cam cover bolts and oil filler cap for more Yellow Zinc.

I gave him the 16 wheel bolts for Black Zinc and the 4 cam cover bolts and oil filler cap for more Yellow Zinc.

Some notes on replacing the booster. It came out from below. The three nuts/washers are within easy grasp from below. However, the flare nuts need to be removed and fitted from above. 6-point10mm flare nut wrench loosened them. Somewhat difficult due to the six points and lots of tubes and lines in the way.

Re-insertion was not bad but the flare nuts needed to be carefully threaded by hand to avoid crossthreading. If the lines don't line up exactly perpendicular, it would have been so easy to cross thread both of them. I left the nuts on the back of the booster loose so I could move the booster around to align the pipes 90 degrees to the holes and back threaded them until they clicked into the threads, then tightened them by hand. If the flange nuts were old and rusty, there would be no way to know if they were cross threaded. In my case I could start both of them by hand from above.

Re-insertion was not bad but the flare nuts needed to be carefully threaded by hand to avoid crossthreading. If the lines don't line up exactly perpendicular, it would have been so easy to cross thread both of them. I left the nuts on the back of the booster loose so I could move the booster around to align the pipes 90 degrees to the holes and back threaded them until they clicked into the threads, then tightened them by hand. If the flange nuts were old and rusty, there would be no way to know if they were cross threaded. In my case I could start both of them by hand from above.

Last edited:

Vacuum testing the booster before re-fitting.

It will be interesting to see how the booster responds to a constant vacuum. The way the thing works is that the brakes are RELEASED by the vacuum on the smaller diaphragm. Adequate vacuum should combat the tendency to not release.

Either way, it should be adequate for my use of the car. I don't see myself driving it any harder than Glickenhaus drives Paolo Martini's Modulo, now that he made it drive-able.

It will be interesting to see how the booster responds to a constant vacuum. The way the thing works is that the brakes are RELEASED by the vacuum on the smaller diaphragm. Adequate vacuum should combat the tendency to not release.

Either way, it should be adequate for my use of the car. I don't see myself driving it any harder than Glickenhaus drives Paolo Martini's Modulo, now that he made it drive-able.