JNewm

True Classic

Hi all--

Yesterday, I installed a second radiator fan on my '81 non-AC X. Both fans are "stock"-style. They both work, but I'm not entirely convinced I have enough power running to them, given the way I installed the second fan. Pre-install, it seemed like the single fan was super-loud. Post-second-fan-install, both fans *seem* quieter. I didn't give it a back-to-back listen while I had it up on the lift yesterday, but based on my recollection, it feels like I may not be running enough power.

So I'm hoping y'all might be able to shed some light on a couple of questions, keeping in mind that I'm pretty ignorant when it comes to all things electrical.

First, is it a bad idea to run both fans off the same wire lead that used to just run the one fan? Did Fiat do it that way for the AC cars? Is it possible/likely I'm not getting enough power to these two fans using this setup?

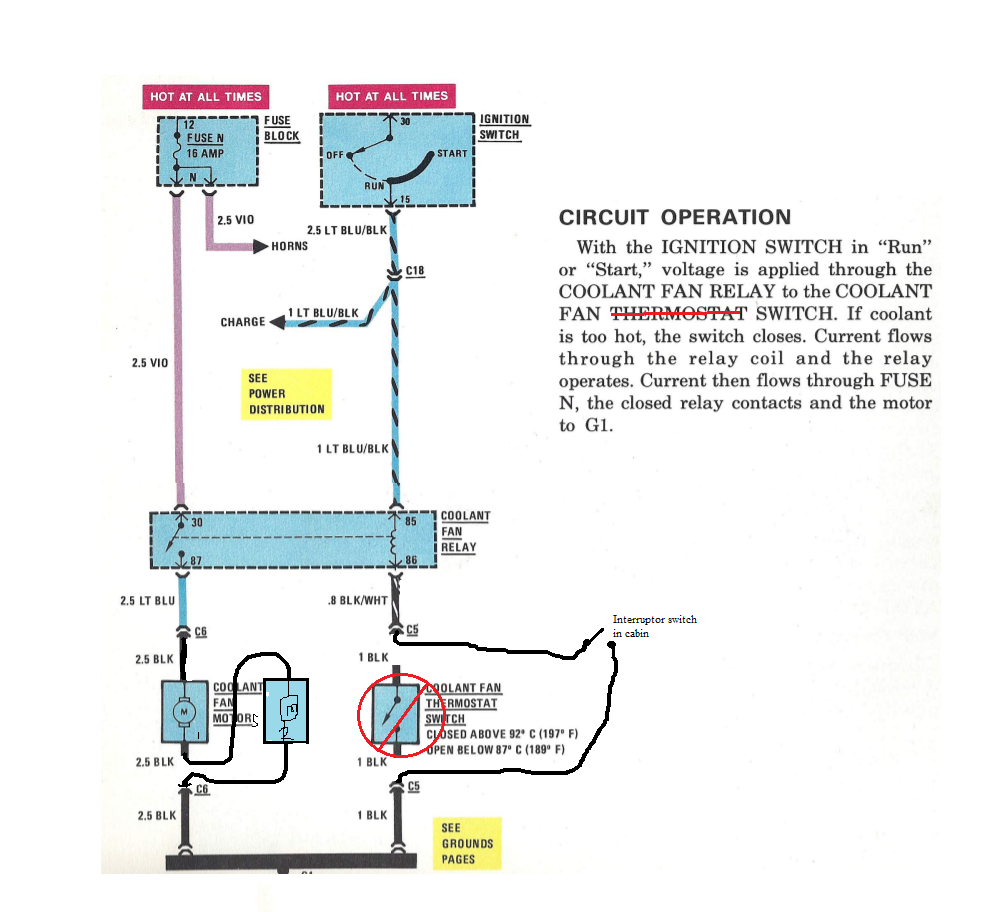

Second, if I do need to get more power to the fan(s), what would be the best way to do so? I've doctored up the wiring diagram to show what I've done thus far below. Basically the second fan is just daisy-chained off the first. (I also disconnected the thermostat switch and ran an interruptor to the cabin, to the extent that's relevant.)

Yesterday, I installed a second radiator fan on my '81 non-AC X. Both fans are "stock"-style. They both work, but I'm not entirely convinced I have enough power running to them, given the way I installed the second fan. Pre-install, it seemed like the single fan was super-loud. Post-second-fan-install, both fans *seem* quieter. I didn't give it a back-to-back listen while I had it up on the lift yesterday, but based on my recollection, it feels like I may not be running enough power.

So I'm hoping y'all might be able to shed some light on a couple of questions, keeping in mind that I'm pretty ignorant when it comes to all things electrical.

First, is it a bad idea to run both fans off the same wire lead that used to just run the one fan? Did Fiat do it that way for the AC cars? Is it possible/likely I'm not getting enough power to these two fans using this setup?

Second, if I do need to get more power to the fan(s), what would be the best way to do so? I've doctored up the wiring diagram to show what I've done thus far below. Basically the second fan is just daisy-chained off the first. (I also disconnected the thermostat switch and ran an interruptor to the cabin, to the extent that's relevant.)