Matt Zerega

Passion, not Practicality.

Good evening rear-engine Fiat motor aficionados.... I have a question for those with experience building the bottom end of 903cc variants. The motor I've got has "100GBC" cast into the side of the block, and a 4-bolt water pump.

I'm beginning to learn that these old Fiat motors aren't broadly supported in the aftermarket...which makes it difficult to find correct parts, and accurate, confident advice. I'm inquiring with you-all (passionate enthusiasts) to address the second part...

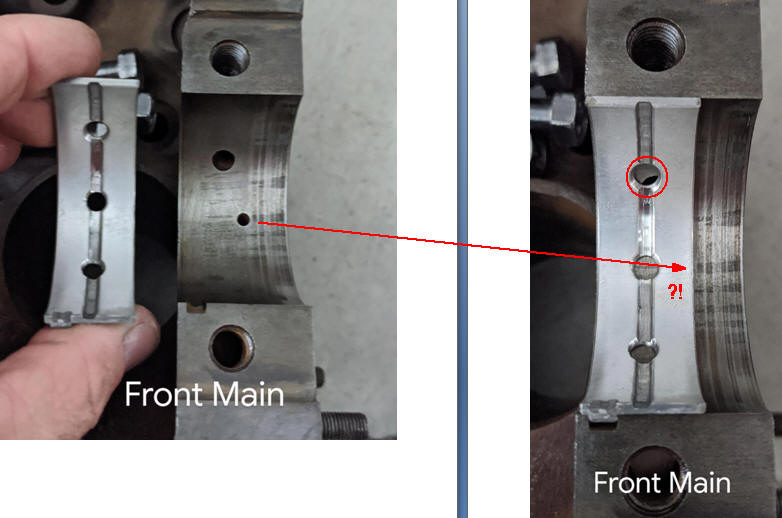

Enough background; here's the issue: I ordered a set of NOS Glacier standard main bearings. They do fit the saddles but the orientation of the oil holes - between the bearing and engine block - look funky...especially on the front main; one of the oil holes in the engine block is completely obstructed and the other is ~80% obstructed. This doesn't seem right at all.

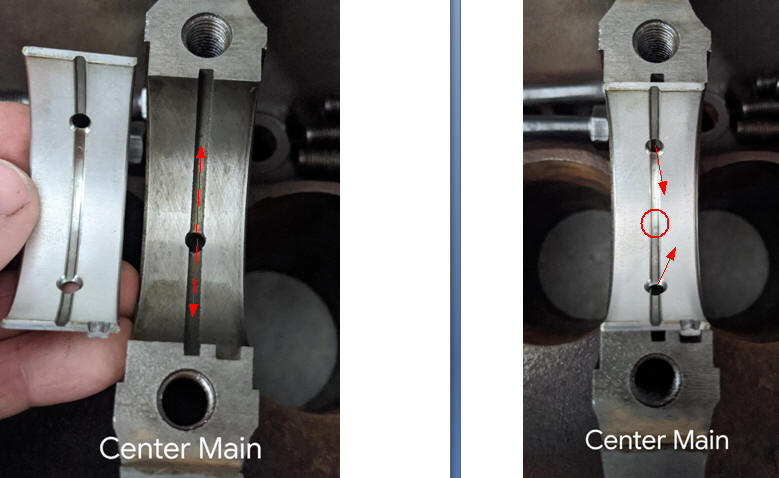

On the center main, the bearing's oil holes are offset about 15mm relative to the engine block's oil holes. I'm not so concerned about the center bearing since oil will flow freely through the groove in the block (behind the bearing shell) and out the two holes in the bearing. Good enough, I think.......

Shall I simply drill the front bearing in alignment with the block's oil holes....or....should I find some other brand/part number?

Any advice from an experienced Fiat 100-series engine builder would certainly be appreciated.

I'm beginning to learn that these old Fiat motors aren't broadly supported in the aftermarket...which makes it difficult to find correct parts, and accurate, confident advice. I'm inquiring with you-all (passionate enthusiasts) to address the second part...

Enough background; here's the issue: I ordered a set of NOS Glacier standard main bearings. They do fit the saddles but the orientation of the oil holes - between the bearing and engine block - look funky...especially on the front main; one of the oil holes in the engine block is completely obstructed and the other is ~80% obstructed. This doesn't seem right at all.

On the center main, the bearing's oil holes are offset about 15mm relative to the engine block's oil holes. I'm not so concerned about the center bearing since oil will flow freely through the groove in the block (behind the bearing shell) and out the two holes in the bearing. Good enough, I think.......

Shall I simply drill the front bearing in alignment with the block's oil holes....or....should I find some other brand/part number?

Any advice from an experienced Fiat 100-series engine builder would certainly be appreciated.