Dr.Jeff

True Classic

EDIT: Note that I am correcting or adding information to this thread. I will try to highlight those changes.

I have a '79 X (1500 5-speed) with factory air conditioning. This thread is not about rebuilding or restoring the system; others like @LarryC have already done a supreme job of documenting that. My intent is about making the AC system more to my personal preference by doing some modifications to it - such as changing how it is operated by the dash controls. I credit @Rodger for motivating me to try this, similar to some mods he made using a "add-on" aftermarket AC system. This will be presented in a few sections as I progress through the project.

The whole HVAC system is very different with "AC" vs a non-AC model. Here's diagrams of both systems:

The two boxes are configured differently and the internal airflow is directed differently. One advantage with the AC version is the two outermost air vents on the dash are actually connected to the HVAC box. Aside from that the general functions are similar - with the AC box adding the AC option - but they are laid out quite differently and therefore have many components that are not interchangeable.

For example the heater core (#19 on the diagram) is different, as discussed in this thread: https://xwebforums.com/forum/index.php?threads/ac-equipped-x1-9-heater-core.40503/#post-373131. My core leaks so I need to either repair or replace it.

Another difference is the blower assembly is a "squirrel cage" style rather than a "fan blade" one. Another forum member is looking into a suitable replacement for the blower motor on the AC style (#30 on the diagram). Fortunately mine is working fine.

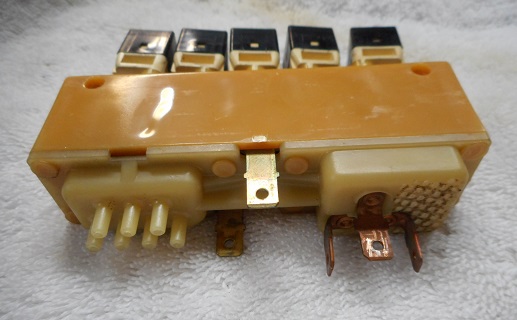

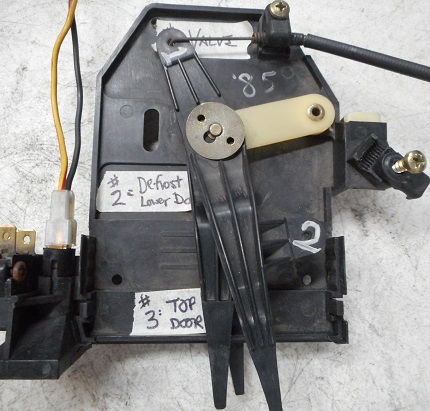

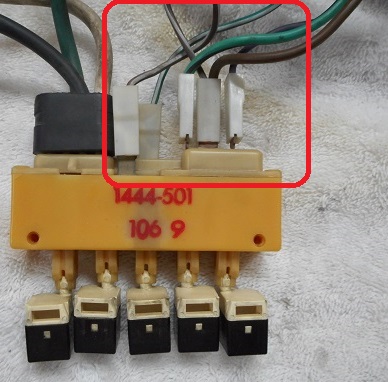

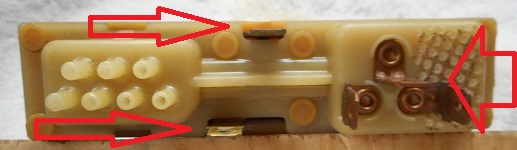

Yet another major difference is the controls for the HVAC system; on the AC version they are vacuum operated (not shown on the diagram) vs the manual levers/cables on a non-AC system (#6 on that diagram). I've found this vacuum control setup to be rather problematic. For one thing they tend to get "vacuum" leaks from multiple points, plus the vacuum solenoids that actuate the "flapper doors" (air circulation control) seem to have a limited operation. As a result I find the airflow through the box isn't well controlled and therefore the system does not function well. Furthermore the operation of the "push button" control panel is a bit finicky and can be prone to breaking. Here is the main vacuum control mechanism:

As you can see it has a combination of vacuum and electrical connections. Pushing "in" any of the control buttons causes the others to pop back up so only one function operates at a time. The buttons actually slide into the unit to activate various vacuum and electrical circuits internally. More on that in a minute. This replaces most of the cables and levers on a non-AC control panel.

Due in part to the typical problems with most vacuum operated systems (e.g. leaks), and in part to the fact this engine is getting a turbo (positive manifold pressure rather than vacuum), I've decided to convert my AC controls from vacuum operated to the manual "cable" operated one as used on the non-AC system. I find the cable system to be much more positive feeling in use, offers better control of the HVAC functions, is more reliable (although it also has its own potential issues), and looks more suited to the interior style of the X. To accomplish this conversion I will need to replace entire control mechanism; the selector panel, solenoids, wiring, etc., between the two systems (AC and non-AC). Fortunately it is a fairly easy job, as many of the components that need to be replaced are a direct fit between them.

Beginning with the control panel. The vacuum control unit (pictured above) fits onto a "framework" that is mounted basically the same as that for the non-AC system. This allows both systems to be installed in the dashboard the same way:

Therefore the "framework" for the two control mechanisms can be interchanged. Like the non-AC system, this mechanism is held by a surround that fits into the dash. Both systems use the same surround. The face plates are different to correspond with the "push button" vs "lever" controls, but they are interchangeable. Here is the surround with the non-AC faceplate:

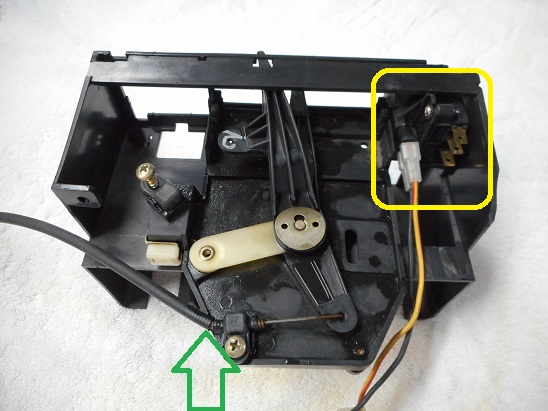

There is one "lever" control on the bottom of the AC version to operate the heater valve (ignore the green arrow and yellow box for now):

That lever is pretty much the same as on the non-AC system. So converting the heater valve control is simple, just use the existing one. The valve is located differently on the AC box so they have different length cables. But the original cable connects to the control lever in the same way (green arrow above).

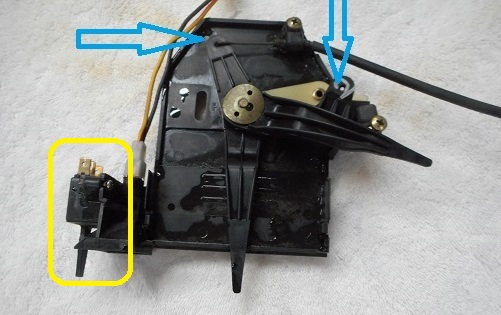

The two additional control levers from the non-AC system will need to be added. Since both control mechanisms fit the same it is easy to swap the non-AC mechanism with its levers as a complete unit (ignore the markings for now):

The AC system has a three speed blower vs the two speed one on the non-AC system. Therefore the control switch for the blower is different, but they are also interchangeable. So simply swap the switch (yellow boxes in the above pics) - they install with two screws. This allows the original wire harness for the blower to remain as it is.

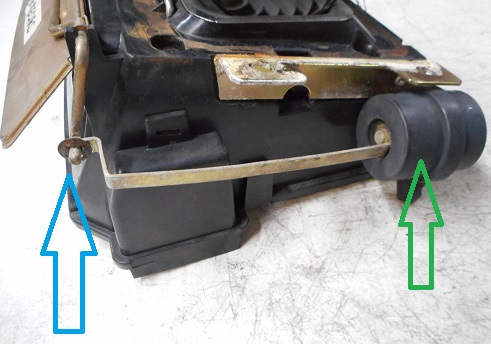

The cables that attach to this mechanism's levers (blue arrows above) operate two air doors ("flappers") on the non-AC box. One allows air to be directed up to the defrost vents. The other moves the main door at the top of the box to allow fresh air in from outside the vehicle. On the AC style box there are three doors, but two of them are inter-connected and move together (see #11, 12, 13 on the "AC diagram"). The reason for this is it provides a "recirculation" function for airflow (which can be used for both AC and heat). So effectively it has two doors as on the non-AC box. They are located differently and the airflow through the system moves differently, but the resultant functions are similar. Therefore the vacuum solenoids that operate those doors on the AC box can be removed and replaced with the cables from the non-AC box. Luckily the doors have points where the cable ends can easily attach to. Here is an example of the defrost duct and vacuum control solenoid (courtesy of Rodger); the blue arrow is the solenoid that will be removed and the yellow arrow is where the cable connects in its place:

The other door has a similar setup and is converted the same way - remove the solenoid (green arrow) and connect the cable (blue arrow):

Due to the different locations of the doors, the lengths of the cables from the non-AC systemmay not be [correction- ARE NOT] ideal when used on the AC box. I haven't reinstalled it yet to find out. [I just tried installing everything and found the cables need some alterations]. But the AC box even has the little provisions to anchor the cable sheaths, as if it was initially designed to be cable operated. [Correction- the AC box has some provisions that can be used to anchor some of the control cables, but others need to be added. I will make further comments about the cables in a later post]

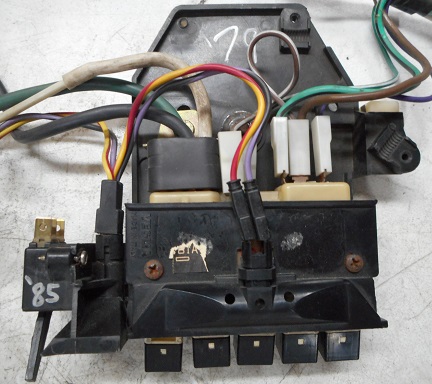

Now the control mechanism has been converted to manual cable operation, the 3-speed blower control has been retained, the heater valve is working, the HVAC box functions are converted, and everything fits into the car the same way as it was...with one exception, the wire harnesses. At this point I have only sorted out some of the differences between the systems' wires. For example the 3-speed blower motor, as described. Also the two control panels (AC and non-AC) have slightly different illumination, but that is only a matter of swapping the little light bulb holders between them. However there are other differences that I still need to address. If you look back at the pics of the "push button" control unit you see it has a vacuum hose connector and some electrical connectors (red):

The vacuum portion is now completely eliminated, but the wires from those electrical connectors still need to be sorted. Some of it is to activate the AC compressor. The X has a very funky (and inefficient) setup for the electrical portion of the AC system. I am eliminating all of the original AC wiring and utilizing a trinary switch in its place (more on this later). Therefore most or all of these wires at the control panel will also be eliminated. It appears the stock AC controls do not allow for adjustment of the air temp; operating the heater at the same time seems to be the only way to regulate it. I will add a AC temp control rheostat as part of my new AC wiring layout. I think the square hole for the old clock in the controls faceplate will be a good location for it. However at this time the car is gutted for body and paint work and the wire harnesses are wrapped in plastic so I cannot trace everything. This info will have to be added to the thread later.

Something that you may find odd when converting to the manual controls is the display icons on the control mechanism faceplace:

For one, the blower switch now has three speeds but the faceplate only shows two. However the switch itself operates correctly. Another thing is the color of the little "arrows". The lowest lever is for the heater valve and that has a blue arrow. The middle lever now operates the fresh air door and it has a red arrow. To me those two arrows should be opposite colors to correspond better with their functions. But unfortunately you cannot simply swap the positions of the controls, the levers themselves are different and will not work well if used differently. [Correction- I later realized that the non-AC box I have was not assembled correctly by someone in its past. The cables and levers were not in their correct positions. Therefore I was mistaken about the functions and icons on the faceplate. I'll add more on this later]. The top lever is still the defrost control, so that icon appears correct. And there is still the same window for the factory clock to the right. The original clock is horrible in my opinion and will be replaced by something else.

I'm sure I'll think of more general details and come up with more pics to also add later. I will start another post to further discuss the workings of the original vacuum control "push button" panel and why it has so many problems.

EDIT: One thing I forgot to mention is the rest of the vacuum system, beyond the control panel and solenoids at the dash/HVAC box. Naturally the vacuum source is from the engine. A single vac hose goes through the firewall to the spare tire well. I noticed the vac hose was partially smashed as it went through the firewall, which would have reduced the airflow through it. In the spare tire well the line goes into a vacuum canister that serves as a 'extra supply of negative pressure air'. From there another single vac line goes along the floor, on the right side of the center tunnel, in the joint between the floor and tunnel. The main wire harness that carries from the front to rear of the car and one of the AC barrier hoses also travel along the same place. On this '79 the soft vac line was under that large wire harness and AC hose, such that when the factory assembly line secured the harness and hose down they pinched off the vac hose. And I mean it was completely occluded, where no air could pass. So the whole vacuum control panel was inoperable since day one on this car. Thankfully all of that is now gone.

Thankfully all of that is now gone.

EDIT: The control levers and cables on the non-AC system are arranged with the defrost lever on top, the heater valve lever in the middle, and the fresh air level on the bottom (I had that wrong earlier). When converting the AC system to these manual controls you can connect the cables in the same locations - thereby retaining the correct icons on the faceplate. However the location of the "doors" on the AC box are different, so the two original cables from the non-AC box are too short to use on the AC box (the heater valve can retain the original AC style cable). I purchased some random control cables from the LADA parts supplier for very little money (links below). I will use them with any needed adjustments on this conversion. It is easy to shorten ones that are too long, but obviously not the opposite.

LADA control cables, two options:

ladapower.com

I got this one. More on it later.

ladapower.com

I got this one. More on it later.

ladapower.com

There may be more options available as well.

ladapower.com

There may be more options available as well. I purchased one of these two (don't recall which one at the moment). Tomorrow I will dig them out, measure the lengths, and look at the part number to identify which ones I got. You may wish to choose another set, or find some from another Fiat or different car. See the following EDIT for more information on the Lada cables.

EDIT: After more testing different arrangements for the control cables I've come up with what I think will work best. I purchased a kit of new cables from the Lada parts source (linked above). I got the one for a 1700 (the first link). The length of these three cables will work great for my conversion to manual controls, as we will see.

As I stated earlier the AC control panel has one lever, located on the bottom of the mechanism. Normally that operates the "heater valve". On the non-AC control panel there are three levers, also with one located on the bottom, but here it operates a different function...the heater valve is controlled by the middle lever. This means the two cables face in opposite directions as they exit the mechanism (the middle and lower levers have cable attachment points on opposite sides). To maintain the correct icon arrangement on the faceplate you will need to swap the heater cable to the middle lever, but this affects the orientation - aiming to the passenger side vs the drivers side (as it did before). I believe the original AC system heater control cable can still be used but it isn't ideal due to the redirection needed. A longer cable would help. Or you may choose to use different levers on the control mechanism; that will orient the direction of the cables much better, allowing the use of shorter ones. But that will also make the icons on the faceplate wrong. In my case I won't be retaining the original heater valve. I'm using one from a VW, mounting it next to the heater core - like where the non-AC box does. So the original non-AC heater cable would work, although I will use one of the new cables (the middle length in the Lada kit - which is just right for my arrangement).

The cable for the "defrost" control also needs to loop around from the opposite direction. Same reason, the orientation of the control levers is different compared to the location of the "flapper" doors on the two boxes. That makes it rather long to prevent binding. I measure it to be around 35" long. Much longer than any of the stock X cables. Fortunately the longest cable in the Lada kit I bought is the right length.

The third lever (now the bottom one) controls the "recirculation" (or "fresh air") function. As it turns out the distance between the control mechanism lever and the attachment to the "flapper" door (for the recirculation) is very short. The orientation of the control mechanism points the cable directly toward the door, so that cable only needs to be about 10" long. The shortest cable in the Lada kit is longer than this but it can easily be cut down to work.

As you can see that kit of cables from Lada works really well for this conversion. And they are incredibly affordable. Even better, the ends all have the correct "attachment shapes" to connect them to everything. Having all new cables makes the controls work much better. All this makes them a great deal for this project.

It is a bit of a struggle getting the cables in their proper locations, orienting them around everything, and attaching them to their related connections. Just doing trial assembly on the workbench was a bitch, I am not looking forward to doing this in the car. And things may end up changing as a result. But at the moment that's the plan.

I have a '79 X (1500 5-speed) with factory air conditioning. This thread is not about rebuilding or restoring the system; others like @LarryC have already done a supreme job of documenting that. My intent is about making the AC system more to my personal preference by doing some modifications to it - such as changing how it is operated by the dash controls. I credit @Rodger for motivating me to try this, similar to some mods he made using a "add-on" aftermarket AC system. This will be presented in a few sections as I progress through the project.

The whole HVAC system is very different with "AC" vs a non-AC model. Here's diagrams of both systems:

The two boxes are configured differently and the internal airflow is directed differently. One advantage with the AC version is the two outermost air vents on the dash are actually connected to the HVAC box. Aside from that the general functions are similar - with the AC box adding the AC option - but they are laid out quite differently and therefore have many components that are not interchangeable.

For example the heater core (#19 on the diagram) is different, as discussed in this thread: https://xwebforums.com/forum/index.php?threads/ac-equipped-x1-9-heater-core.40503/#post-373131. My core leaks so I need to either repair or replace it.

Another difference is the blower assembly is a "squirrel cage" style rather than a "fan blade" one. Another forum member is looking into a suitable replacement for the blower motor on the AC style (#30 on the diagram). Fortunately mine is working fine.

Yet another major difference is the controls for the HVAC system; on the AC version they are vacuum operated (not shown on the diagram) vs the manual levers/cables on a non-AC system (#6 on that diagram). I've found this vacuum control setup to be rather problematic. For one thing they tend to get "vacuum" leaks from multiple points, plus the vacuum solenoids that actuate the "flapper doors" (air circulation control) seem to have a limited operation. As a result I find the airflow through the box isn't well controlled and therefore the system does not function well. Furthermore the operation of the "push button" control panel is a bit finicky and can be prone to breaking. Here is the main vacuum control mechanism:

As you can see it has a combination of vacuum and electrical connections. Pushing "in" any of the control buttons causes the others to pop back up so only one function operates at a time. The buttons actually slide into the unit to activate various vacuum and electrical circuits internally. More on that in a minute. This replaces most of the cables and levers on a non-AC control panel.

Due in part to the typical problems with most vacuum operated systems (e.g. leaks), and in part to the fact this engine is getting a turbo (positive manifold pressure rather than vacuum), I've decided to convert my AC controls from vacuum operated to the manual "cable" operated one as used on the non-AC system. I find the cable system to be much more positive feeling in use, offers better control of the HVAC functions, is more reliable (although it also has its own potential issues), and looks more suited to the interior style of the X. To accomplish this conversion I will need to replace entire control mechanism; the selector panel, solenoids, wiring, etc., between the two systems (AC and non-AC). Fortunately it is a fairly easy job, as many of the components that need to be replaced are a direct fit between them.

Beginning with the control panel. The vacuum control unit (pictured above) fits onto a "framework" that is mounted basically the same as that for the non-AC system. This allows both systems to be installed in the dashboard the same way:

Therefore the "framework" for the two control mechanisms can be interchanged. Like the non-AC system, this mechanism is held by a surround that fits into the dash. Both systems use the same surround. The face plates are different to correspond with the "push button" vs "lever" controls, but they are interchangeable. Here is the surround with the non-AC faceplate:

There is one "lever" control on the bottom of the AC version to operate the heater valve (ignore the green arrow and yellow box for now):

That lever is pretty much the same as on the non-AC system. So converting the heater valve control is simple, just use the existing one. The valve is located differently on the AC box so they have different length cables. But the original cable connects to the control lever in the same way (green arrow above).

The two additional control levers from the non-AC system will need to be added. Since both control mechanisms fit the same it is easy to swap the non-AC mechanism with its levers as a complete unit (ignore the markings for now):

The AC system has a three speed blower vs the two speed one on the non-AC system. Therefore the control switch for the blower is different, but they are also interchangeable. So simply swap the switch (yellow boxes in the above pics) - they install with two screws. This allows the original wire harness for the blower to remain as it is.

The cables that attach to this mechanism's levers (blue arrows above) operate two air doors ("flappers") on the non-AC box. One allows air to be directed up to the defrost vents. The other moves the main door at the top of the box to allow fresh air in from outside the vehicle. On the AC style box there are three doors, but two of them are inter-connected and move together (see #11, 12, 13 on the "AC diagram"). The reason for this is it provides a "recirculation" function for airflow (which can be used for both AC and heat). So effectively it has two doors as on the non-AC box. They are located differently and the airflow through the system moves differently, but the resultant functions are similar. Therefore the vacuum solenoids that operate those doors on the AC box can be removed and replaced with the cables from the non-AC box. Luckily the doors have points where the cable ends can easily attach to. Here is an example of the defrost duct and vacuum control solenoid (courtesy of Rodger); the blue arrow is the solenoid that will be removed and the yellow arrow is where the cable connects in its place:

The other door has a similar setup and is converted the same way - remove the solenoid (green arrow) and connect the cable (blue arrow):

Due to the different locations of the doors, the lengths of the cables from the non-AC system

Now the control mechanism has been converted to manual cable operation, the 3-speed blower control has been retained, the heater valve is working, the HVAC box functions are converted, and everything fits into the car the same way as it was...with one exception, the wire harnesses. At this point I have only sorted out some of the differences between the systems' wires. For example the 3-speed blower motor, as described. Also the two control panels (AC and non-AC) have slightly different illumination, but that is only a matter of swapping the little light bulb holders between them. However there are other differences that I still need to address. If you look back at the pics of the "push button" control unit you see it has a vacuum hose connector and some electrical connectors (red):

The vacuum portion is now completely eliminated, but the wires from those electrical connectors still need to be sorted. Some of it is to activate the AC compressor. The X has a very funky (and inefficient) setup for the electrical portion of the AC system. I am eliminating all of the original AC wiring and utilizing a trinary switch in its place (more on this later). Therefore most or all of these wires at the control panel will also be eliminated. It appears the stock AC controls do not allow for adjustment of the air temp; operating the heater at the same time seems to be the only way to regulate it. I will add a AC temp control rheostat as part of my new AC wiring layout. I think the square hole for the old clock in the controls faceplate will be a good location for it. However at this time the car is gutted for body and paint work and the wire harnesses are wrapped in plastic so I cannot trace everything. This info will have to be added to the thread later.

Something that you may find odd when converting to the manual controls is the display icons on the control mechanism faceplace:

For one, the blower switch now has three speeds but the faceplate only shows two. However the switch itself operates correctly.

I'm sure I'll think of more general details and come up with more pics to also add later. I will start another post to further discuss the workings of the original vacuum control "push button" panel and why it has so many problems.

EDIT: One thing I forgot to mention is the rest of the vacuum system, beyond the control panel and solenoids at the dash/HVAC box. Naturally the vacuum source is from the engine. A single vac hose goes through the firewall to the spare tire well. I noticed the vac hose was partially smashed as it went through the firewall, which would have reduced the airflow through it. In the spare tire well the line goes into a vacuum canister that serves as a 'extra supply of negative pressure air'. From there another single vac line goes along the floor, on the right side of the center tunnel, in the joint between the floor and tunnel. The main wire harness that carries from the front to rear of the car and one of the AC barrier hoses also travel along the same place. On this '79 the soft vac line was under that large wire harness and AC hose, such that when the factory assembly line secured the harness and hose down they pinched off the vac hose. And I mean it was completely occluded, where no air could pass. So the whole vacuum control panel was inoperable since day one on this car.

EDIT: The control levers and cables on the non-AC system are arranged with the defrost lever on top, the heater valve lever in the middle, and the fresh air level on the bottom (I had that wrong earlier). When converting the AC system to these manual controls you can connect the cables in the same locations - thereby retaining the correct icons on the faceplate. However the location of the "doors" on the AC box are different, so the two original cables from the non-AC box are too short to use on the AC box (the heater valve can retain the original AC style cable). I purchased some random control cables from the LADA parts supplier for very little money (links below). I will use them with any needed adjustments on this conversion. It is easy to shorten ones that are too long, but obviously not the opposite.

LADA control cables, two options:

Lada Niva 1700 Heating + Ventilation Control Cables Kit

Lada Niva 1700 Heating + Ventilation Control Cables Kit Heating 1700

Lada 21011 2101 2102 1200 1300 Heating + Ventilation Control Cables Kit

Lada 21011 2101 2102 1200 1300 Heating + Ventilation Control Cables Kit Heating

EDIT: After more testing different arrangements for the control cables I've come up with what I think will work best. I purchased a kit of new cables from the Lada parts source (linked above). I got the one for a 1700 (the first link). The length of these three cables will work great for my conversion to manual controls, as we will see.

As I stated earlier the AC control panel has one lever, located on the bottom of the mechanism. Normally that operates the "heater valve". On the non-AC control panel there are three levers, also with one located on the bottom, but here it operates a different function...the heater valve is controlled by the middle lever. This means the two cables face in opposite directions as they exit the mechanism (the middle and lower levers have cable attachment points on opposite sides). To maintain the correct icon arrangement on the faceplate you will need to swap the heater cable to the middle lever, but this affects the orientation - aiming to the passenger side vs the drivers side (as it did before). I believe the original AC system heater control cable can still be used but it isn't ideal due to the redirection needed. A longer cable would help. Or you may choose to use different levers on the control mechanism; that will orient the direction of the cables much better, allowing the use of shorter ones. But that will also make the icons on the faceplate wrong. In my case I won't be retaining the original heater valve. I'm using one from a VW, mounting it next to the heater core - like where the non-AC box does. So the original non-AC heater cable would work, although I will use one of the new cables (the middle length in the Lada kit - which is just right for my arrangement).

The cable for the "defrost" control also needs to loop around from the opposite direction. Same reason, the orientation of the control levers is different compared to the location of the "flapper" doors on the two boxes. That makes it rather long to prevent binding. I measure it to be around 35" long. Much longer than any of the stock X cables. Fortunately the longest cable in the Lada kit I bought is the right length.

The third lever (now the bottom one) controls the "recirculation" (or "fresh air") function. As it turns out the distance between the control mechanism lever and the attachment to the "flapper" door (for the recirculation) is very short. The orientation of the control mechanism points the cable directly toward the door, so that cable only needs to be about 10" long. The shortest cable in the Lada kit is longer than this but it can easily be cut down to work.

As you can see that kit of cables from Lada works really well for this conversion. And they are incredibly affordable. Even better, the ends all have the correct "attachment shapes" to connect them to everything. Having all new cables makes the controls work much better. All this makes them a great deal for this project.

It is a bit of a struggle getting the cables in their proper locations, orienting them around everything, and attaching them to their related connections. Just doing trial assembly on the workbench was a bitch, I am not looking forward to doing this in the car. And things may end up changing as a result. But at the moment that's the plan.

Last edited: