You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advice required on 5 speed gearbox rebuild.

- Thread starter rizthewiz

- Start date

ng_randolph

Bjorn H

Not quite. The bearing race must be fully seated. You adjust preload using the appropriate shims between the retaining flange and housing (other end of the differential) upon assembly. This is quite critical, so be sure to follow the directions in the factory service manual.I think I may have worked this one out myself. Once I tighten the carrier cover to the correct torque it should seat the race so it is on zero preload.

Dr.Jeff

True Classic

I know you've already removed the bearing races, but I'll throw out another possible method for it. I haven't tried it on the X case yet (I'll be rebuilding three of them eventually), but this has worked for me on very similar races in other trans. Using two small "claw foot" pry bars, you can 'walk' out the races. The bars I'm referring to look like this:

The tip (red arrow) gets behind the race in the recess. Then they can lever the race up from side to side.

If the race isn't stuck you may get it with only one bar. But don't over do it in one spot or you could damage the case.

The tip (red arrow) gets behind the race in the recess. Then they can lever the race up from side to side.

If the race isn't stuck you may get it with only one bar. But don't over do it in one spot or you could damage the case.

Steve Hoelscher

True Classic

Peter, sorry for taking so long to follow up on this. Its been a hectic few days and we actually tried to have a mini vacation over Memorial Day weekend.

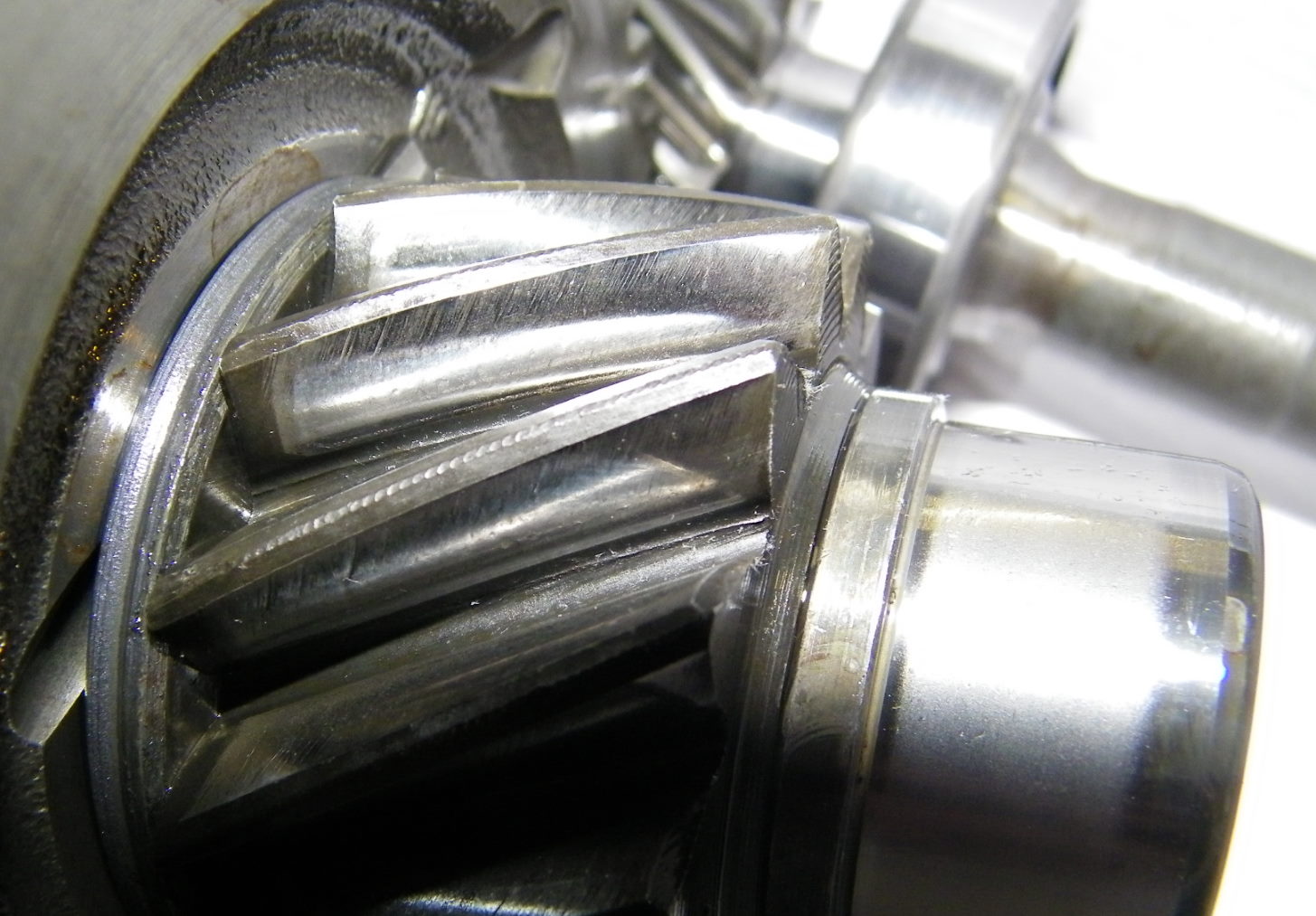

Anyway, it was this photo that told me what was likely the problem:

In this photo it was easy to see the rust on the input shaft above first gear.

Having seen rust like this before its not uncommon for it to be on the exposed, polished, face of the gear teeth. 1st is likely rusted but the coarse tooth pitch and the ratio wouldn't likely result in a whine. The same is likely for 2nd. But later year gearsets have a finer tooth pitch on 3rd and any rust on them will cause pitting and a distinct whine. Thus I asked for a photo.

While its hard to see due to the angle and lighting my bet is that there is far more than what I can see in this photo.

The input shaft will need replacement. The pitting certainly causes the whine but it will also cause the teeth to eventually fail and it will begin shedding teeth and make a major mess.

It looks like 4th might be less affected but my guess is you'll see pitting on all of the input shaft's teeth, especially 1st through 3rd.

Anyway, it was this photo that told me what was likely the problem:

In this photo it was easy to see the rust on the input shaft above first gear.

Having seen rust like this before its not uncommon for it to be on the exposed, polished, face of the gear teeth. 1st is likely rusted but the coarse tooth pitch and the ratio wouldn't likely result in a whine. The same is likely for 2nd. But later year gearsets have a finer tooth pitch on 3rd and any rust on them will cause pitting and a distinct whine. Thus I asked for a photo.

While its hard to see due to the angle and lighting my bet is that there is far more than what I can see in this photo.

The input shaft will need replacement. The pitting certainly causes the whine but it will also cause the teeth to eventually fail and it will begin shedding teeth and make a major mess.

It looks like 4th might be less affected but my guess is you'll see pitting on all of the input shaft's teeth, especially 1st through 3rd.

Last edited:

Steve Hoelscher

True Classic

I know you've already removed the bearing races, but I'll throw out another possible method for it. I haven't tried it on the X case yet (I'll be rebuilding three of them eventually), but this has worked for me on very similar races in other trans. Using two small "claw foot" pry bars, you can 'walk' out the races. The bars I'm referring to look like this:

View attachment 32630

The tip (red arrow) gets behind the race in the recess. Then they can lever the race up from side to side.

If the race isn't stuck you may get it with only one bar. But don't over do it in one spot or you could damage the case.

Don't use that to try and pull the diff bearing race. You'll crack the case too easily. Remove the seal and drive it out from the back side.

Steve Hoelscher

True Classic

I think I may have worked this one out myself. Once I tighten the carrier cover to the correct torque it should seat the race so it is on zero preload.

You need to ensure the race is fully seated in the bellhousing half of the case. Then, after installing the outer case half install the outer race. You'll need to drive it in with a driver as it is a light press fit. Seat it against the diff bearing and then shim to spec in the service manual.

Dr.Jeff

True Classic

Although this method has worked for me many times with other similar trans, I can see why it wouldn't be a good idea for these old Fiat units. When I look at the images of case failures (such as in the thread linked below), it makes me think these aluminum castings are much more brittle than the ones I'm more familiar with (other makes of vehicles from the same era). There are times when a bearing race lives in a blind hole and no access from the other side. I have one of the pullers designed for such applications but at times it doesn't get the job done. And that's when I use the lever method. Luckily I've never had any damage from doing it, but as I say that's with other makes of 70's FWD trans. So I'll definitely avoid it with my X trans.Don't use that to try and pull the diff bearing race. You'll crack the case too easily.

Random Transmission Failures

There always seems to be some interest in some of the odd things I find with X1/9 transmissions. So I though I would start a thread for that instead of posting this stuff elsewhere. With this winter's round of transmission builds I have run across a couple of common issues I see regularly. I...

xwebforums.com

Steve Hoelscher

True Classic

Peter, you're welcome and I wish you luck. Incorrect diff preload will make for a lot of noise.

Jeff, the problem with that tool and the X case is the area it puts the force on as a fulcrum. The case isn't very strong there and they do have a tendency to crack.

I will note that I have one of those tools and a couple of variations. They usually work nicely but given how easy it is to drive out the race from the back side there is no need to take the risk.

Jeff, the problem with that tool and the X case is the area it puts the force on as a fulcrum. The case isn't very strong there and they do have a tendency to crack.

I will note that I have one of those tools and a couple of variations. They usually work nicely but given how easy it is to drive out the race from the back side there is no need to take the risk.

Dr.Jeff

True Classic

Steve and Peter, would it help to try and polish out the rusty surfaces? I realize that would be a bit time consuming for the gear teeth. But if it will help the current shaft to live longer and run quieter, then that gives greater opportunity to find a suitable replacement. Or are there any surface finishing techniques that will work here...blasting, tumbling, dipping, coatings?I'll reassemble and use this until I can source a replacement input shaft.

Steve Hoelscher

True Classic

Jeff, I haven't tried it but I doubt polishing would fix the problem. The hardened surface gets pitted from the rust and polishing won't remove the pitting. If polishing removed the pitting then running the gear would as well.

The rust actually pits the surface and that's where the whine comes from. I wouldn't invest the time and effort to try and polish. Midwest-Bayless sells the shafts. There are three versions. The one in the photo is one of the two later versions. If you don't know what year, count the teeth on first gear.

The rust actually pits the surface and that's where the whine comes from. I wouldn't invest the time and effort to try and polish. Midwest-Bayless sells the shafts. There are three versions. The one in the photo is one of the two later versions. If you don't know what year, count the teeth on first gear.

So I am in the process of trying to calculate the shim thickness required for the diff preload. I have assembled the case halves without a gasket as I want to have the shims ready before final assembly.

The current shims are 2.05 mm and 0.20 mm. I have calculated the clearance with just the 2.05 mm shim installed. The most stable clearance I can get is 0.27 mm. The specs in the manual require a clearance between 0.08 to 0.12 mm. Meaning that I require a shim of 1.90 -1.86 mm.

I am intending to use RTV as a gasket. Will the thickness of the RTV affect these measurements on final assembly?

Alternatively, the paper gasket I have is 0.64 mm. If I use this it would add that amount to the shim required.

Do my calculations appear correct? This to me is the most complicated and crucial part of the rebuild and I hope to get it right this time.

Many thanks

Peter

The current shims are 2.05 mm and 0.20 mm. I have calculated the clearance with just the 2.05 mm shim installed. The most stable clearance I can get is 0.27 mm. The specs in the manual require a clearance between 0.08 to 0.12 mm. Meaning that I require a shim of 1.90 -1.86 mm.

I am intending to use RTV as a gasket. Will the thickness of the RTV affect these measurements on final assembly?

Alternatively, the paper gasket I have is 0.64 mm. If I use this it would add that amount to the shim required.

Do my calculations appear correct? This to me is the most complicated and crucial part of the rebuild and I hope to get it right this time.

Many thanks

Peter

Steve Hoelscher

True Classic

If you are going to use a gasket, you MUST use the gasket when setting up the preload. Measuring the gasket and adding it to the clearance will result in excessive preload and the diff bearings failing.

RTV will not affect the preload tolerance. However, it is crucial that the case be torqued properly.

Having done dozens of these I can tell you that its as much art as science (or mathematics). Shimming valves is far easier. I was able to obtain an inventory of shims so I don't have to calculate shim thickness and order the desired thickness, assuming I can find the designated size.

RTV will not affect the preload tolerance. However, it is crucial that the case be torqued properly.

Having done dozens of these I can tell you that its as much art as science (or mathematics). Shimming valves is far easier. I was able to obtain an inventory of shims so I don't have to calculate shim thickness and order the desired thickness, assuming I can find the designated size.

lookforjoe

True Classic

How is the diff preload set on these? On the Volvo & Honda transaxles there are preload shims behind one of the carrier bearing races, so the races are pressed fully into the seats. It seems odd that the race would not be up against whatever seat/ridge is present in the Fiat transaxle, IMO.

EDIT - never mind, as I went through the posts, the later ones didn't show - I believe I understand from Steve's post why that race is not set further out (recessed in the casing) now.

EDIT - never mind, as I went through the posts, the later ones didn't show - I believe I understand from Steve's post why that race is not set further out (recessed in the casing) now.

Last edited:

Steve Hoelscher

True Classic

This is why I tell people not to trust everything you read on the internet. The signal to noise ratio is pretty good on this forum but in many other car forums the "consensus" results from whoever has the time to fill the threads with their posts. Example: I read a post where a guy was checking the engine oil level with the engine running. There was great debate among the participants that; "yes, checking the oil level with the engine running was the only way to get an accurate reading". This despite the fact that the owners and service manuals state that the engine should be at operating temperature and off. No amount of rational explanation could dissuade them. Now, it is "common knowledge" on that forum that you check the oil level with the engine running.

To check the diff bearing preload, follow the service manual guidelines. I have seen lots of diff bearing failures over the years. Frequently from units that were recently rebuilt and didn't have the bear preload properly set. I had a few failures myself in units I built early on and didn't do it properly.

Anybody that says to put any amount of torque on the seal carrier when checking preload either has no idea how bearings work, or has never built one of these units successfully.

To check the diff bearing preload, follow the service manual guidelines. I have seen lots of diff bearing failures over the years. Frequently from units that were recently rebuilt and didn't have the bear preload properly set. I had a few failures myself in units I built early on and didn't do it properly.

Anybody that says to put any amount of torque on the seal carrier when checking preload either has no idea how bearings work, or has never built one of these units successfully.

GregS

ProjectX

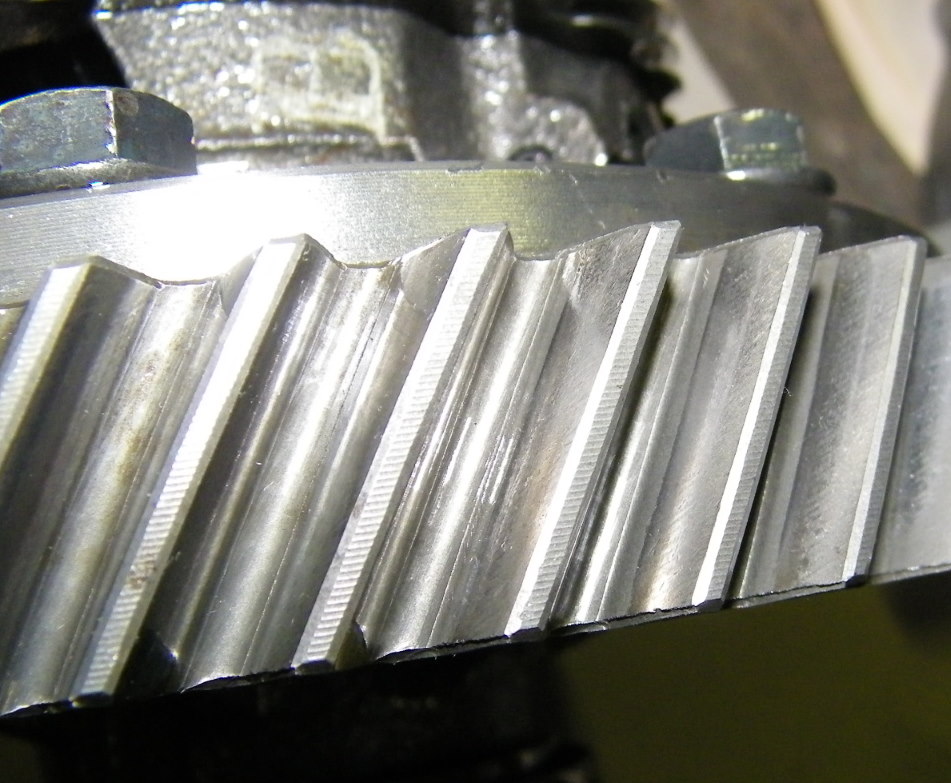

Thanks for confirming preload Steve. This photo is of my diff bearing (preload done the correct way), it has only done about 2,000km in my track car, it doesn't look too good to me so will be replaced (both). The gearbox has a noticeable whine at high speed, full power in fifth, could this be the bearings? The crown wheel and pinion aren't too bad, but not perfect, 5th gears look fine.

Steve Hoelscher

True Classic

Hi Greg,

That bearing race does look like it was too tight. That would absolutely cause a whine that was louder, and higher pitched, tracking with speed.

Also, the pinion shaft race looks pretty tired. That particular race is a common to show excessive wear. I replace them in most every unit I build.

I would be curious as to what oil you are using. The pinion gear seems to show wear that is perpendicular to the axis of the shaft. This typically results from the oil breaking down and not adequately lubricating the face of the pinion teeth. That said, getting good photos of the wear on the face of a gear tooth is difficult. So I might be seeing a reflection or a pattern from oil residue.

That bearing race does look like it was too tight. That would absolutely cause a whine that was louder, and higher pitched, tracking with speed.

Also, the pinion shaft race looks pretty tired. That particular race is a common to show excessive wear. I replace them in most every unit I build.

I would be curious as to what oil you are using. The pinion gear seems to show wear that is perpendicular to the axis of the shaft. This typically results from the oil breaking down and not adequately lubricating the face of the pinion teeth. That said, getting good photos of the wear on the face of a gear tooth is difficult. So I might be seeing a reflection or a pattern from oil residue.

GregS

ProjectX

Steve, I have replaced all the bearings since then, they all showed similar signs of wear despite the low mileage. The oil was Castrol Manual Syntrans 75W-80 GL4 full synthetic. I have been using it also in my road X 4 speed for over 10 years without issue.

I have now changed to Redline MTL in both trans just in case.

I have now changed to Redline MTL in both trans just in case.

Steve Hoelscher

True Classic

Greg, Castrol Synthetic is a good GL4 lubricant and one I suggest as an alternate assuming MTL isn't available.