dragonsgate

True Classic

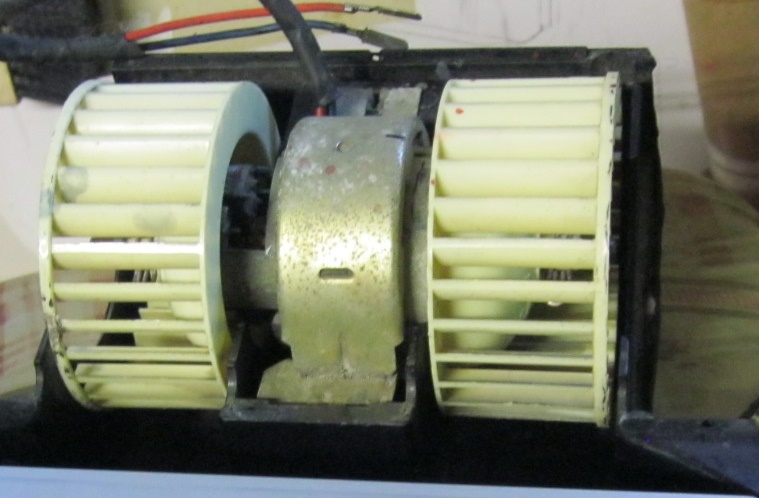

Anyone know what the amp draw is on X19 A/C motors?

This one in particular. I think it is from a 1975.

This one in particular. I think it is from a 1975.

You can make your multimeter into a high current ammeter if it has a reasonably accurate low value resistance measurement function. You could measure the resistance across the fuse for the circuit with the system off. Then you can measure the voltage across it with the motor running and use Ohm's Law I = V/ R. To improve the resistance measurement accuracy, measure the resistance of the leads touching just each other and subtract it from the value measured across the fuse.Did some testing and the older motor I am using for A/C is a lot more drag than the blower motor from the 84 X.

With just the 84 fan motor running and I spin the alternator up to 2000 to 3500 rpm I get 13.35 volts on the multi meter.

With everything unplugged I get 13.5 volts and it drops to 12.2 when I hit the A/C switch at 3500 rpm.

One would think I would have electrician tools but I don't have anything but a multi meter that only goes up to 10 amps.

Everything in the electric drive system is pretty much plug and play so I rely on the expertise of others.

I just ordered a better meter for when I work on the old motor and am looking for a newer more efficient setup that I could possibly adapt.