lezesig1

expatriot

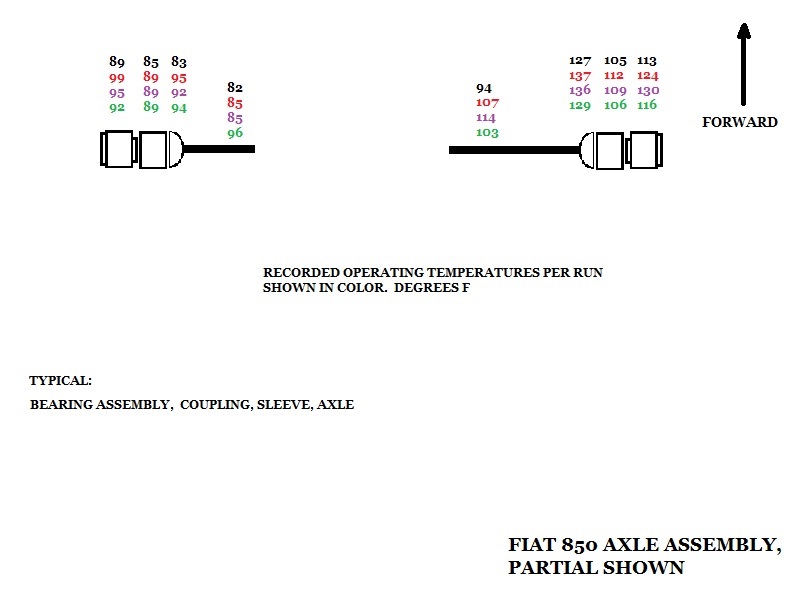

AXLE ASSEMBLY OPERATING TEMPERATURE.

Perceived heat difference between the left side and right side after driving.

Hand on parts after driving told me that there was a difference. I measured it. Please see the attached rough sketch.

My right side runs hotter.

Anybody else noticed this difference ?

Note: Brake drum left side and right side are cool to barely warm to the touch. Easy braking on each run.

Apron and axle spline are well lubricated and sealed. Spline mesh is good on each side.

Ideas ????

Thanks upfront for any insight

lezesig

'72spi

Perceived heat difference between the left side and right side after driving.

Hand on parts after driving told me that there was a difference. I measured it. Please see the attached rough sketch.

My right side runs hotter.

Anybody else noticed this difference ?

Note: Brake drum left side and right side are cool to barely warm to the touch. Easy braking on each run.

Apron and axle spline are well lubricated and sealed. Spline mesh is good on each side.

Ideas ????

Thanks upfront for any insight

lezesig

'72spi