TonyK

True Classic

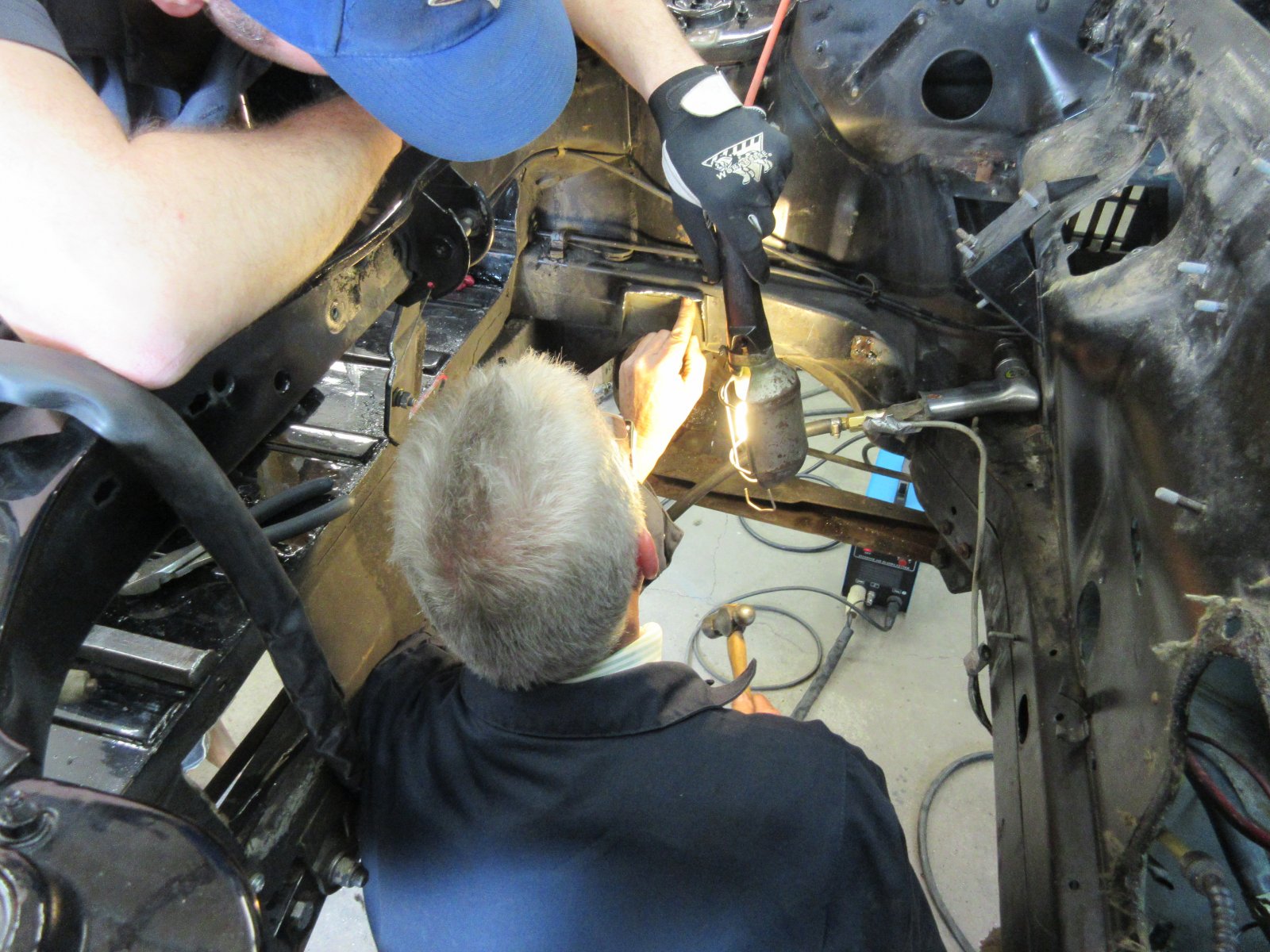

April 13/2019 Bob arrived yesterday and we have been working in the shop most of the day preparing for the installation of the engine. My nephew Mike stopped by to help and see what was going on. Here are a few pictures of what we have been doing and where we are. End of day one.

TonyK.

Grimsby Ontario Canada,

With Bob Martin from Radcliff Kentucky.

TonyK.

Grimsby Ontario Canada,

With Bob Martin from Radcliff Kentucky.