jimmyx

True Classic

I'll start this thread in the right place as the "New Addition" thread is veering off the rails now.

Finished up the right side floor pan. Patches welded in, wire brushed metal and hit it with rust converter. Unless it's blasted, there is always rust there. After that applied 2 coats of rust encapsulator. Will lay down the generic Dynamat after the left side is completed. I was hopeful that the left side could be repaired the same way, but the amount of damage is right on the line, so I ordered a pan on ebay and will use maybe half of it for the repair.

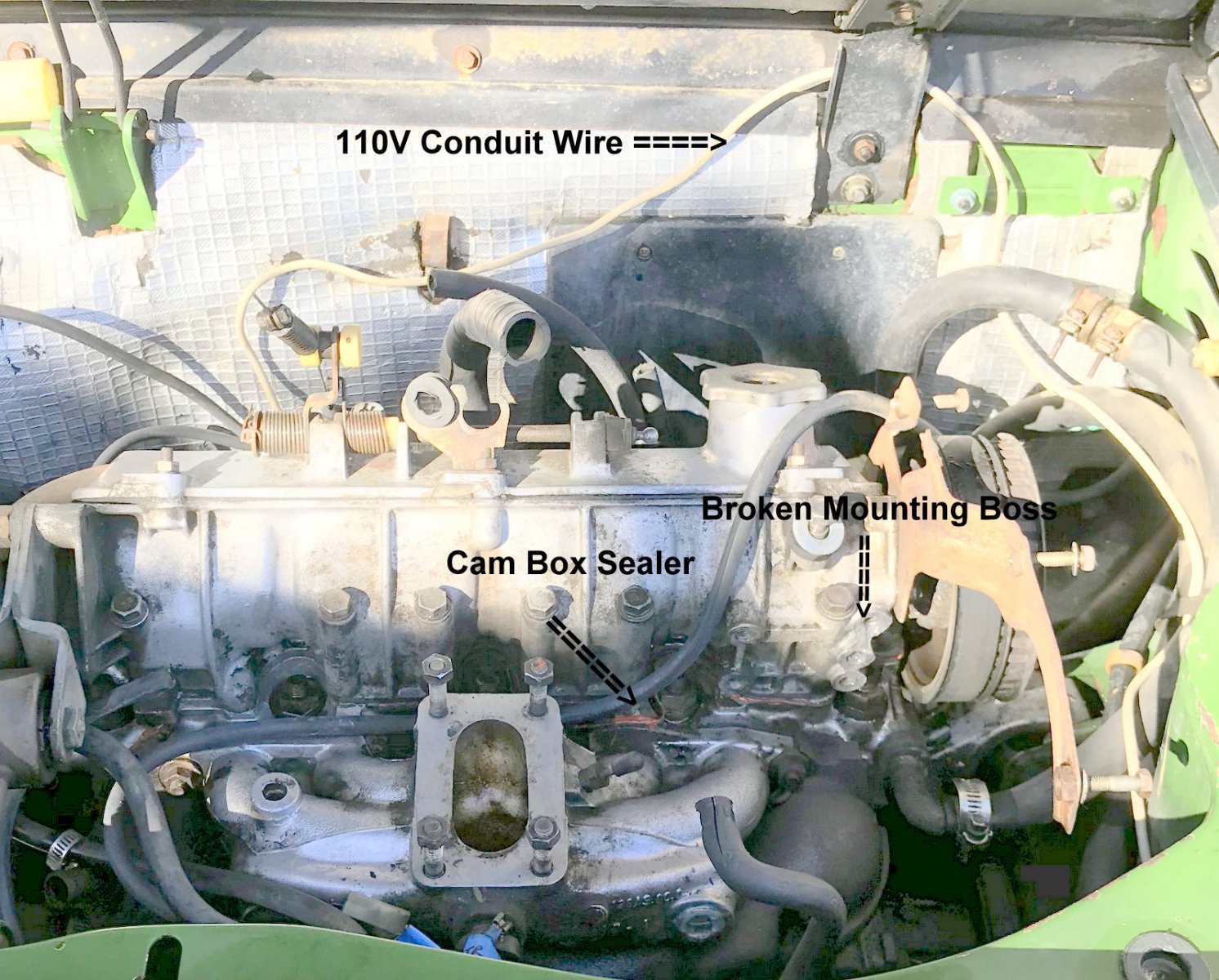

I decided to hit the engine with a power washer to see what's going on back there. We all have experienced the DPO, but this one has suffered the DPOS (dreaded prior owner's shop). The PO had zero mechanical inclination as evidenced by a mountain of repair invoices, so he had to pay good money to have some idiot make a mess. Alternator was changed at some point to an internally regulated 1-wire. The shop must have run out of wire for the alternator to starter lug feed wire, so hey, let's just use something out of the building's old fuse box and mount it behind a hood hinge just for good measure. Air pump bracket is held by 4 bolts - why waste time? Just use 2 so the mounting point breaks off the head. The cam box was removed as evidenced by the cheap RTV. Why would the cam box need to be removed? Probably to get the head off to replace the gasket after an engine got a little too toasty. All this with just a cursory look, who knows what other mechanical horrors are hiding in the shadows. I was hoping to change all the fluids and rubber to see how this would run. Have to scrap those plans as it is a fools errand. The oil smells like spar varnish - identical to the fuel tank. Better off to just drop this lump out and see if it's a candidate for a rebuild.

Finished up the right side floor pan. Patches welded in, wire brushed metal and hit it with rust converter. Unless it's blasted, there is always rust there. After that applied 2 coats of rust encapsulator. Will lay down the generic Dynamat after the left side is completed. I was hopeful that the left side could be repaired the same way, but the amount of damage is right on the line, so I ordered a pan on ebay and will use maybe half of it for the repair.

I decided to hit the engine with a power washer to see what's going on back there. We all have experienced the DPO, but this one has suffered the DPOS (dreaded prior owner's shop). The PO had zero mechanical inclination as evidenced by a mountain of repair invoices, so he had to pay good money to have some idiot make a mess. Alternator was changed at some point to an internally regulated 1-wire. The shop must have run out of wire for the alternator to starter lug feed wire, so hey, let's just use something out of the building's old fuse box and mount it behind a hood hinge just for good measure. Air pump bracket is held by 4 bolts - why waste time? Just use 2 so the mounting point breaks off the head. The cam box was removed as evidenced by the cheap RTV. Why would the cam box need to be removed? Probably to get the head off to replace the gasket after an engine got a little too toasty. All this with just a cursory look, who knows what other mechanical horrors are hiding in the shadows. I was hoping to change all the fluids and rubber to see how this would run. Have to scrap those plans as it is a fools errand. The oil smells like spar varnish - identical to the fuel tank. Better off to just drop this lump out and see if it's a candidate for a rebuild.