KBabcock

True Classic

Just finished replacing just about all the major heater hose and thought I would do a quick write up of the process. In this project I replaced the 4 main hose which attach to the metal pipes running under the car, The short 90 degree piece attached to the thermostat housing and the heater core hose running from the engine to the small metal pipe running under the car. The few remaining lines where already replaced so I omitted them here.

Let's start with 4 main hoses off the Metal pipe under the car. The two in the back are pretty straight forward and hardest thing was pulling them out and pushing them in because they are large 90 molded pieces.

Let me state a few things before proceeding, I was replacing this hoses and using new compression bands, worm screw type clamps for 1.25" hose and 5/8" hose but because the metal tubes under the car in the rear did not have much of a lip at the ends I decided to go with Stainless Steel T-Bolt Clamps with Rounded Bands on the rear main pipe ends, they wider and will hold better. These were 41-46mm size to fit 1.25" hoses.

Because I was not reusing the hoses I cut off any stubborn hoses with a utility knife. I suggest cutting the rubber pipes about 2" parallel to the metal pipe and not all the way through to avoid scaring the metal pipe. Once you slip a screw driver between the pipe and the rubber hose the remaining rubber will just split the rest of the way.

So back to the rear pipes going into the engine bay. Once you remove the pipes from the tubes and engine you need to pull them out. The passenger side comes out easiest up through the engine bay while I found the Driver's side comes out easiest from under the car pulling down. These were pretty straight forward. One more note my car is an 85 and has a metal coating on the pipes under the car which were corroding into a white powder, I wired brushed them down and painted them before installing the hoses.

Next up are the front two hose from the pipes to the radiator. The one on the drivers side is very straightforward and easy. The one on the passenger side is hard to get at on the radiator connection up top. I heard a lot of people talking about this one and was starting to get worried about having to deal with it. It turned out to be not that bad for me. Like all the clamps, spray them the day before with penetrating oil and let sit 24 hours. This did not help one of the clamps, they are a odd compression design and the head snapped off. I used a bolt cutter to cut the treated screw and it came right off. To get to the bolt up top I used a long 1/4" extension with a universal joint and had no problems on my car, your mileage may very.

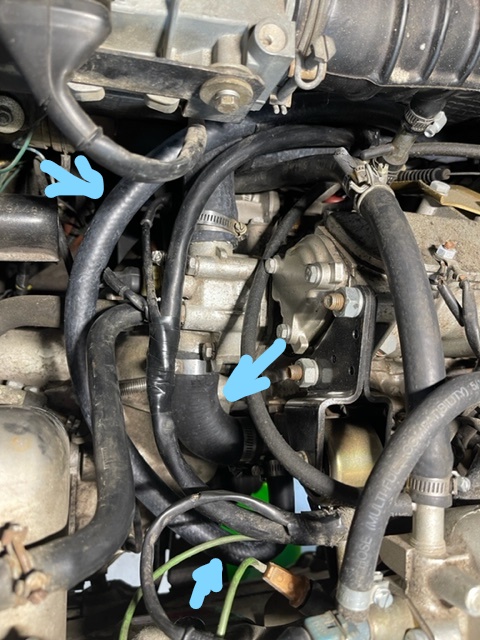

Now this next hose I thought would be easy but due to its location there is a lot of stuff in the way. To get to this and the heater core hose (They are right next to each other) I removed the top of the air filter with the intake pipe. Also remove the access panel in the Truck to better access to these hoses. This is a small 90 degree hose about 5"x5" and I just cut it off which made that part easy. The new pipe is very hard to fit, I highly recommend letting it sit in the sun for 30 minutes or in front of a heat to make it more pliable. Because of the two hose fitting being so close together you have to really push and twist this hose to get it on, use a large screw drive but be careful not to damage the pipe. This pipe is shown with the center arrow. The other two arrow show the hose to the heater core pipe which we will address now.

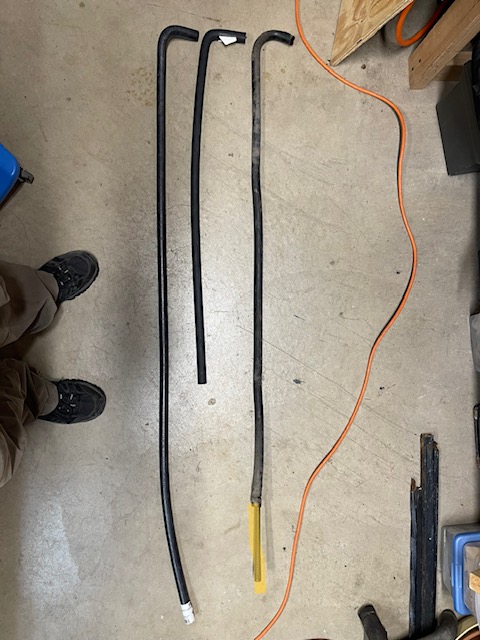

The heater core line is different then the others because you need to sourse this line yourself. The other lines I installed where available from Midwest Bayless or Vicks. For this line they say just use standard 5/8" heater hose. This is not a good idea in my book because the hose attaches to the engine facing the back of the car and needs to do a U-turn to get to the front of the engine where it drops under the car. It is very easy for it to crimp as its a tighter turn. You are best to find a hose with a molded 90 turn. Below are three hoses. The one on the right is the hose I removed (OEM), you can see the 90 bend after 4 to 5 inches. The yellow highlight at the end of this hose is just a piece of pipe I had to put into the hose to straighten it for the picture, just ignore it. This line is 48" on the long section. The hose in the center was a NAPA part someone recommended and was two short, it was on 36" on the long end. The one on the left is the one I sourced. It is a 90 degree molded bend 5" x 60", this is 12" longer than the OEM hose. When I ordered it I did not know the correct size exactly so went with the upper limit. As it turned out this was a good move. It allowed me to run the pipe in a way that limited interference. You can see this hose in the picture above with the blue arrows at the top and bottom of the picture. Notice the 90 bend and you will see why you want it and not a straight hose. This part was bought on ebay https://www.ebay.com/itm/164547786341 the seller was called KE-Sales. But if you type 5/8" Heater hose molded 90 degree 5"x60" You will find a number of people selling them. The 60" is also easier to sourse then a 48".

Update thanks to Dan, NAPA Part (5"x60") which was only $25 https://www.napaonline.com/en/p/NBH9814

I feel the 48" would have been two short. When all was done I had 4" of extra hose cut off the 60" end.

So that's it, if anyone has any other tips please add them in. Enjoy.

Let's start with 4 main hoses off the Metal pipe under the car. The two in the back are pretty straight forward and hardest thing was pulling them out and pushing them in because they are large 90 molded pieces.

Let me state a few things before proceeding, I was replacing this hoses and using new compression bands, worm screw type clamps for 1.25" hose and 5/8" hose but because the metal tubes under the car in the rear did not have much of a lip at the ends I decided to go with Stainless Steel T-Bolt Clamps with Rounded Bands on the rear main pipe ends, they wider and will hold better. These were 41-46mm size to fit 1.25" hoses.

Because I was not reusing the hoses I cut off any stubborn hoses with a utility knife. I suggest cutting the rubber pipes about 2" parallel to the metal pipe and not all the way through to avoid scaring the metal pipe. Once you slip a screw driver between the pipe and the rubber hose the remaining rubber will just split the rest of the way.

So back to the rear pipes going into the engine bay. Once you remove the pipes from the tubes and engine you need to pull them out. The passenger side comes out easiest up through the engine bay while I found the Driver's side comes out easiest from under the car pulling down. These were pretty straight forward. One more note my car is an 85 and has a metal coating on the pipes under the car which were corroding into a white powder, I wired brushed them down and painted them before installing the hoses.

Next up are the front two hose from the pipes to the radiator. The one on the drivers side is very straightforward and easy. The one on the passenger side is hard to get at on the radiator connection up top. I heard a lot of people talking about this one and was starting to get worried about having to deal with it. It turned out to be not that bad for me. Like all the clamps, spray them the day before with penetrating oil and let sit 24 hours. This did not help one of the clamps, they are a odd compression design and the head snapped off. I used a bolt cutter to cut the treated screw and it came right off. To get to the bolt up top I used a long 1/4" extension with a universal joint and had no problems on my car, your mileage may very.

Now this next hose I thought would be easy but due to its location there is a lot of stuff in the way. To get to this and the heater core hose (They are right next to each other) I removed the top of the air filter with the intake pipe. Also remove the access panel in the Truck to better access to these hoses. This is a small 90 degree hose about 5"x5" and I just cut it off which made that part easy. The new pipe is very hard to fit, I highly recommend letting it sit in the sun for 30 minutes or in front of a heat to make it more pliable. Because of the two hose fitting being so close together you have to really push and twist this hose to get it on, use a large screw drive but be careful not to damage the pipe. This pipe is shown with the center arrow. The other two arrow show the hose to the heater core pipe which we will address now.

The heater core line is different then the others because you need to sourse this line yourself. The other lines I installed where available from Midwest Bayless or Vicks. For this line they say just use standard 5/8" heater hose. This is not a good idea in my book because the hose attaches to the engine facing the back of the car and needs to do a U-turn to get to the front of the engine where it drops under the car. It is very easy for it to crimp as its a tighter turn. You are best to find a hose with a molded 90 turn. Below are three hoses. The one on the right is the hose I removed (OEM), you can see the 90 bend after 4 to 5 inches. The yellow highlight at the end of this hose is just a piece of pipe I had to put into the hose to straighten it for the picture, just ignore it. This line is 48" on the long section. The hose in the center was a NAPA part someone recommended and was two short, it was on 36" on the long end. The one on the left is the one I sourced. It is a 90 degree molded bend 5" x 60", this is 12" longer than the OEM hose. When I ordered it I did not know the correct size exactly so went with the upper limit. As it turned out this was a good move. It allowed me to run the pipe in a way that limited interference. You can see this hose in the picture above with the blue arrows at the top and bottom of the picture. Notice the 90 bend and you will see why you want it and not a straight hose. This part was bought on ebay https://www.ebay.com/itm/164547786341 the seller was called KE-Sales. But if you type 5/8" Heater hose molded 90 degree 5"x60" You will find a number of people selling them. The 60" is also easier to sourse then a 48".

Update thanks to Dan, NAPA Part (5"x60") which was only $25 https://www.napaonline.com/en/p/NBH9814

I feel the 48" would have been two short. When all was done I had 4" of extra hose cut off the 60" end.

So that's it, if anyone has any other tips please add them in. Enjoy.

Attachments

Last edited: