Rupunzell

Bernice Loui

They put 4 spot welds on the US of A scorpion head light stops.. why?

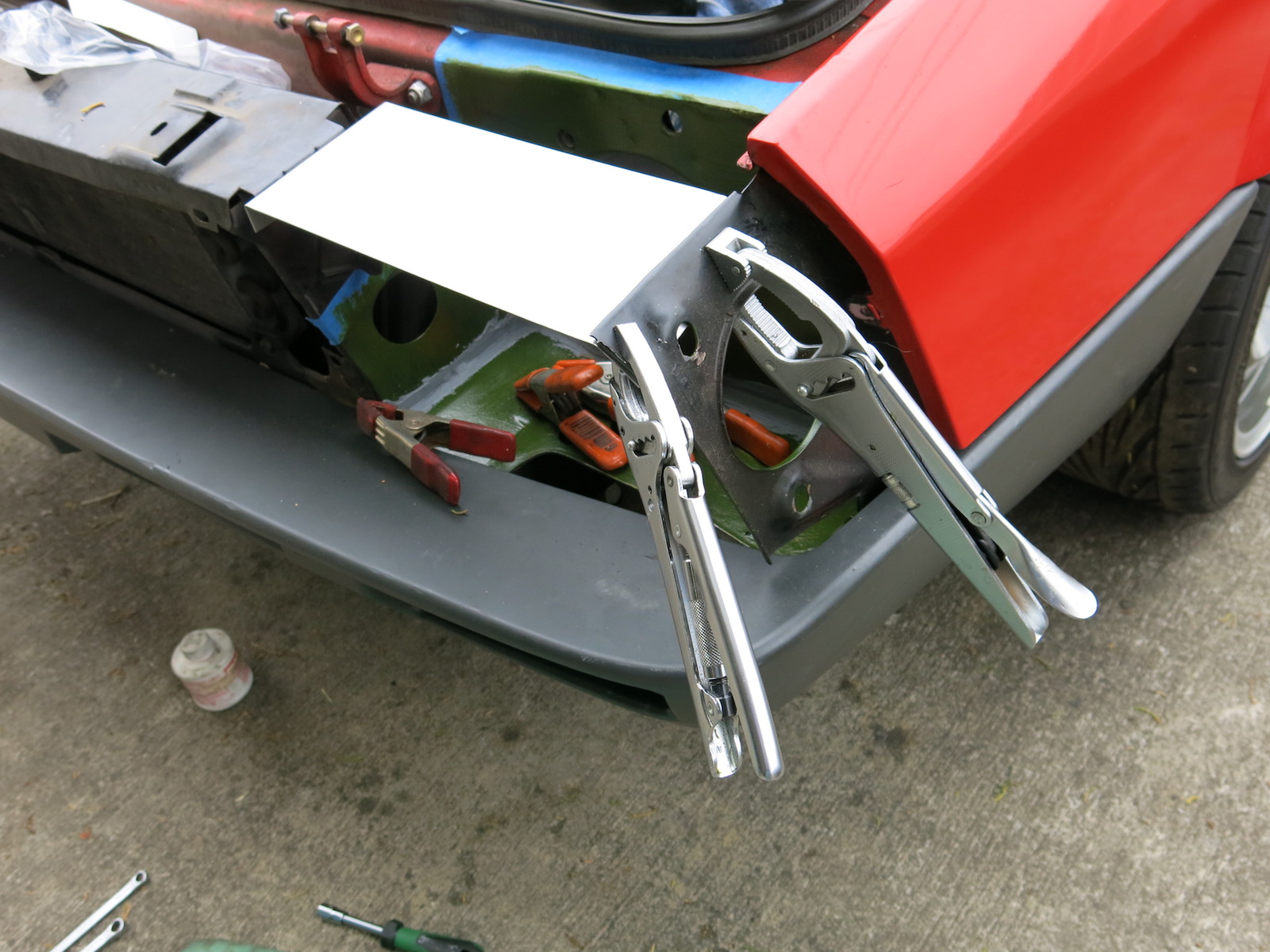

Stainless steel top plate fitting. This is the area that was cut out from the Monte to fit US of A

semi pop up headlights. SST was chosen due to no requirement for paint or finishing other than

clean up. The plate is held in by #10-32 bolts, washers and prevailing torque nuts, no welding.

Facom (French made) locking pliers at work stabilizing the plate position for holes to be drilled.

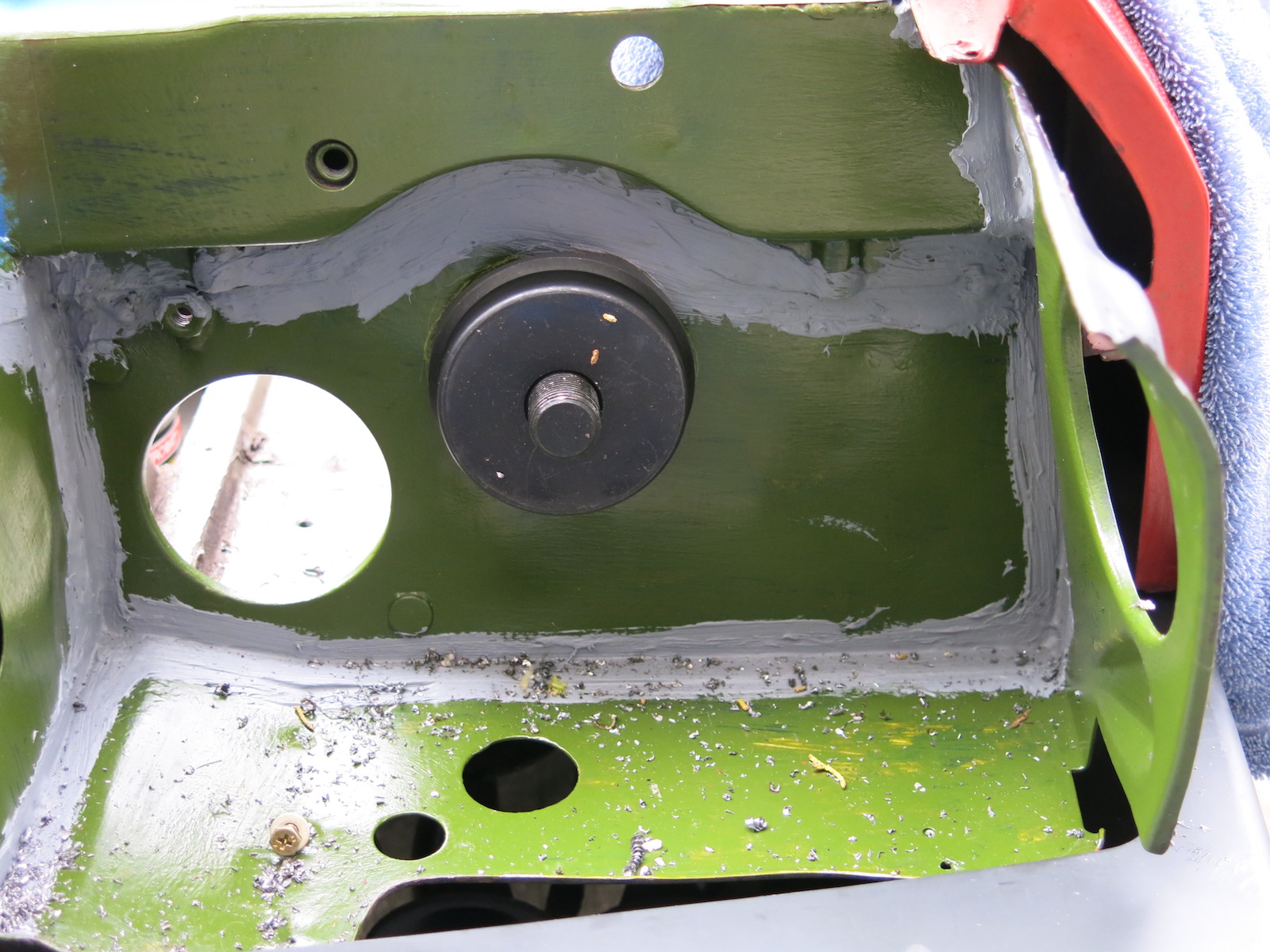

Locating where the missing bulb hole for the Monte head lamp assembly needs to be.

Much a "one punch deal"..

bulb hole location, then center drill, drill out to 75mm hydraulic punch die hole.

Set up the 75mm dia hydraulic hole punch.

The hydraulic hole punch piston.

Makes a good round hole. The polymer surround on the back of the Monte HL is

to keep flying Goooo out of the frunk.

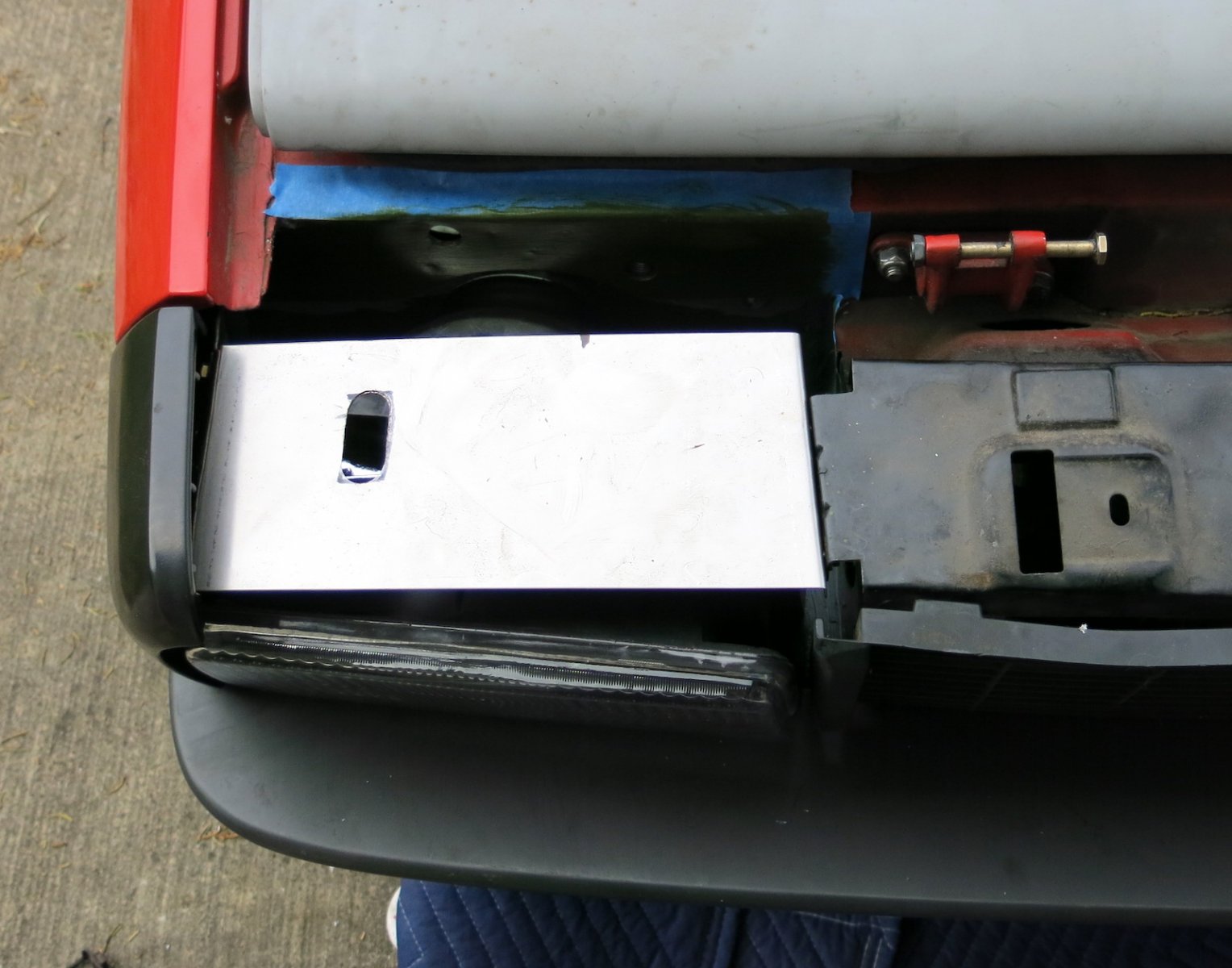

Top view of the set plate. The slot was done on the BP milling machine. Sharpiee marker

location marks for the nose top brakes is just visible on the edges of this slot.

Top view with the Monte head lamp in place.

View of the front with missing Monte parts in place.

Headlamps fit and look proper now. Next will be making all the brackets needed.

Bernice

Stainless steel top plate fitting. This is the area that was cut out from the Monte to fit US of A

semi pop up headlights. SST was chosen due to no requirement for paint or finishing other than

clean up. The plate is held in by #10-32 bolts, washers and prevailing torque nuts, no welding.

Facom (French made) locking pliers at work stabilizing the plate position for holes to be drilled.

Locating where the missing bulb hole for the Monte head lamp assembly needs to be.

Much a "one punch deal"..

bulb hole location, then center drill, drill out to 75mm hydraulic punch die hole.

Set up the 75mm dia hydraulic hole punch.

The hydraulic hole punch piston.

Makes a good round hole. The polymer surround on the back of the Monte HL is

to keep flying Goooo out of the frunk.

Top view of the set plate. The slot was done on the BP milling machine. Sharpiee marker

location marks for the nose top brakes is just visible on the edges of this slot.

Top view with the Monte head lamp in place.

View of the front with missing Monte parts in place.

Headlamps fit and look proper now. Next will be making all the brackets needed.

Bernice