lanciahf

True Classic

After my futile search for soft motor mounts I took Mike Haynes advice and made my own. He suggested making molds and pouring urethane. I decided on a Durometer rating of 40 from Mcmaster -Carr. http://www.mcmaster.com/#liquid-urethane/=14jvkh8

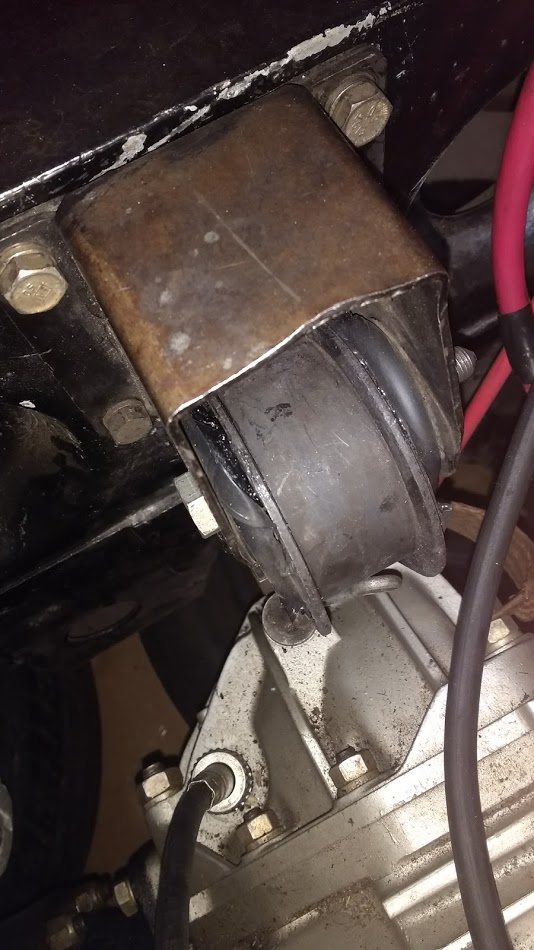

Scorpion mounts differ from X1/9 mounts. The metal sleeve where the bolt passes through protrudes 1/4" on each side of the mount and is encased in rubber.

I had a buddy make some molds out of wood. To center & recess the metal sleeve the mold has a 7/8 wide center hole and is about 1/4" deep. Two wood rings were glued to the molds to center the mount, they stick up about 1/8". A long bolt passes through the two pieces of wood holding the metal tube in place and the wood rings hold the mount centered. In order for the urethane not to stick to the wood I melted wax and brushed it on the wood.

My first attempt resulted in disaster as I did not apply enough wax and the urethane seeped out. I should have tested my molds first..... I thought the urethane would be thick enough not to leak out. So after much cleaning I was ready for another attempt and yes I had to buy another can.

My second attempt I borrowed some clay from my son and used it as a sealer.

This time the urethane stayed in place. After 24 hours I was able to remove the wood molds easy enough, but the long bolt was a pain. I should have applied wax to that also. As a result the metal sleeve spins in the urethane which I think is okay??? Anyway I coated the metal sleeve and Urethane in Loctite PL-30 caulk (Approved in all of the Honda Forums for quick motor mount fixes.) This should keep the sleeve from rotating and provide an added noise insulator. Trying to apply the caulk and be neat was not very successful.

I'll give the rubber a couple of days to get hard and reinstall the mounts.

Scorpion mounts differ from X1/9 mounts. The metal sleeve where the bolt passes through protrudes 1/4" on each side of the mount and is encased in rubber.

I had a buddy make some molds out of wood. To center & recess the metal sleeve the mold has a 7/8 wide center hole and is about 1/4" deep. Two wood rings were glued to the molds to center the mount, they stick up about 1/8". A long bolt passes through the two pieces of wood holding the metal tube in place and the wood rings hold the mount centered. In order for the urethane not to stick to the wood I melted wax and brushed it on the wood.

My first attempt resulted in disaster as I did not apply enough wax and the urethane seeped out. I should have tested my molds first..... I thought the urethane would be thick enough not to leak out. So after much cleaning I was ready for another attempt and yes I had to buy another can.

My second attempt I borrowed some clay from my son and used it as a sealer.

This time the urethane stayed in place. After 24 hours I was able to remove the wood molds easy enough, but the long bolt was a pain. I should have applied wax to that also. As a result the metal sleeve spins in the urethane which I think is okay??? Anyway I coated the metal sleeve and Urethane in Loctite PL-30 caulk (Approved in all of the Honda Forums for quick motor mount fixes.) This should keep the sleeve from rotating and provide an added noise insulator. Trying to apply the caulk and be neat was not very successful.

I'll give the rubber a couple of days to get hard and reinstall the mounts.