Made some progress!

With the exception of glassing in the nose are of some RC airplanes I built as a kid, this is my first fiberglass project. It's going surprisingly well thus far.

I used a diamond tip cutting wheel (thanks HF for a $4 pack of five) and trimmed the inner piece, leaving a mold for the frame which fits the contours of the firewall. I epoxied a swatch from an old thick t-shirt to the perimeter and left as much slack in the center as I could get without causing wrinkles on the sides. Let it cure... Waxed a balloon, let it dry, and then pressed it into the center of the frame to make a large cavity where the distributor will fit. Painted it with resin, let it cure, and removed the balloon.

Wifey isn't loving the fumes from the resin which I am struggling to contain in the basement (gives her headaches

) and it's too cold in the garage, so I will take a few days off, and then go to the local maker space and reinforce the back-side of the bulge with more glass mat. After that, I'll wax it up and attempt to pull-off a completed part ready for paint. Having some fun with this...

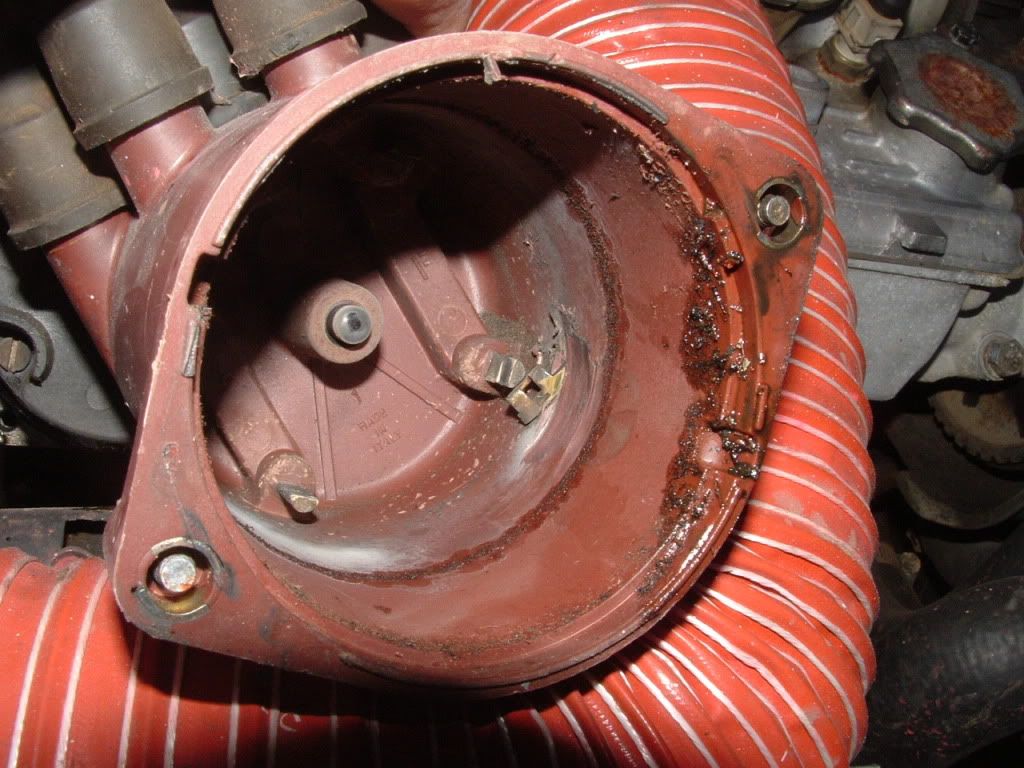

Frame with t-shirt slack t-shirt material.

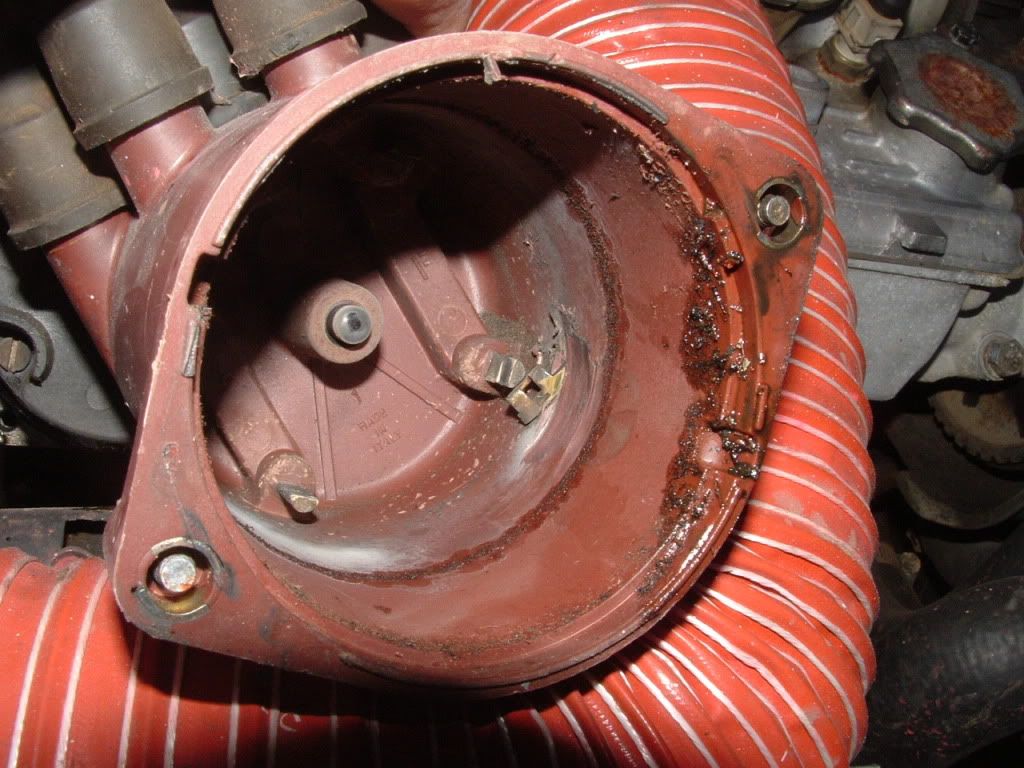

Back-side showing the frame with cut-away center section.

Waxed balloon pressed into place with tape on the backside holding it against the frame. Applying resin.

Current state of frame with "Buddha belly" modification. Will test-fit today and fully expect it to accommodate the longer distributor but to interfere with spare tire (which is ok since I carry an inflator and green slime instead).