You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electric fuel pump install

- Thread starter karhawk

- Start date

PaulD

Paul Davock

Add a relay

that is activated when the oil pressure light is on. Hook up your wire from the ignition switch to the common, and continue it to the pump from the terminal that on when the relay not activated (normally closed i think).

The pump will not come on until you build a bit of oil pressure, which could give you a bit more cranking. I would be interested knowing in how long this is if you choose to go this route.

You could remove this delay by adding an accusump unit, but in the event of a crash, that would defeat the function of shutting off the pump when the engine quit, until the accusump bled out all of its pressure.

Last year I crewed at vintage races where a corvette crashed and tore off a gas line, and the fuel pump kept running, feeding the fire that had started. The corner marshals were the heroes in this case, no one was hurt. (The car looked totaled, but it is back this year looking great.)

Another thought: that circuit already exists from the switch on the flap in the air metering unit. That will give you your relay. Of course in a race car, most of that circuitry will be gone.

Paul Davock

that is activated when the oil pressure light is on. Hook up your wire from the ignition switch to the common, and continue it to the pump from the terminal that on when the relay not activated (normally closed i think).

The pump will not come on until you build a bit of oil pressure, which could give you a bit more cranking. I would be interested knowing in how long this is if you choose to go this route.

You could remove this delay by adding an accusump unit, but in the event of a crash, that would defeat the function of shutting off the pump when the engine quit, until the accusump bled out all of its pressure.

Last year I crewed at vintage races where a corvette crashed and tore off a gas line, and the fuel pump kept running, feeding the fire that had started. The corner marshals were the heroes in this case, no one was hurt. (The car looked totaled, but it is back this year looking great.)

Another thought: that circuit already exists from the switch on the flap in the air metering unit. That will give you your relay. Of course in a race car, most of that circuitry will be gone.

Paul Davock

Last edited:

Pete Whitstone

True Classic

Pretty sure Karhawk just added

An electric fuel pump to replace his mechanical one on a carbureted car. If it was an FI car, the wiring to disconnect the pump under no engine pressure would already be present.

And hard starting with an electric pump should not be an issue on a carbed car, unless it's sat long enough for the fuel to have evaporated out of the bowl.

Pete

Another thought: that circuit already exists from the switch on the flap in the air metering unit. That will give you your relay. Of course in a race car, most of that circuitry will be gone.

Paul Davock

An electric fuel pump to replace his mechanical one on a carbureted car. If it was an FI car, the wiring to disconnect the pump under no engine pressure would already be present.

And hard starting with an electric pump should not be an issue on a carbed car, unless it's sat long enough for the fuel to have evaporated out of the bowl.

Pete

rachaeljf

True Classic

You can get relays that detect the ignition is running to turn on the pump. They are commonly used with L-Jet, for example on the Uno Turbo Mk1. They simply have an extra terminal connecting to the coil along with the usual terminals for a relay.

They are intended for FI but should be good for a carb car too.

The other option is an inertia switch.

They are intended for FI but should be good for a carb car too.

The other option is an inertia switch.

fiatmonkey

Tim Hoover

I did this as well. I tried a few things including using the connection form the oil sender as the ground (bad idea). Better would be a relay that accepts the second connector from the send to signal the relay and power to your switch.

The car is in storage for now so wouldn't be able to look at the setup unless I could find the diagram.

The car is in storage for now so wouldn't be able to look at the setup unless I could find the diagram.

I will be designing a kit at some point

...when I'm ready to put the engine into Mac-X.

My plan: Build an FI fuel delivery system close to stock to feed dual DCNF-40's. (which is obviously not stock)

I like the late model FI fuel delivery system. (if you can't tell already)

Since an FI system needs some fuel pump management, I'll be taking signals from 2 sources: (to activate the pump)

1. The oil pressure sender

2. An (approx) 5 second signal timer to indicate the ignition is active.

The signal will be re-settable with the ignition switch.

I'm guessing (at this point) that a roughly 5-second pump activation upon a key-start will get enough fuel into the carb floats to get things running. More on this as it develops.

In essence, the oil pressure sensor replaces the switch inside the AFM, and the 5-second timer replaces the Bosch ECU's "fuel pump on" timer.

There are a few ways of doing this and I'll find one that is easy, inexpensive, easily repairable and predictable.

Another project... :whistle:

...when I'm ready to put the engine into Mac-X.

My plan: Build an FI fuel delivery system close to stock to feed dual DCNF-40's. (which is obviously not stock)

I like the late model FI fuel delivery system. (if you can't tell already)

Since an FI system needs some fuel pump management, I'll be taking signals from 2 sources: (to activate the pump)

1. The oil pressure sender

2. An (approx) 5 second signal timer to indicate the ignition is active.

The signal will be re-settable with the ignition switch.

I'm guessing (at this point) that a roughly 5-second pump activation upon a key-start will get enough fuel into the carb floats to get things running. More on this as it develops.

In essence, the oil pressure sensor replaces the switch inside the AFM, and the 5-second timer replaces the Bosch ECU's "fuel pump on" timer.

There are a few ways of doing this and I'll find one that is easy, inexpensive, easily repairable and predictable.

Another project... :whistle:

Last edited:

Joe F

Hi Miles, Lo Maintenance

Put me down for a kit...

I have an electric pump feeding my carb and at cold start-up, I can hear it run hard for 2 or three seconds until it quiets down with back pressure (I have an overflow line from the carb to the tank).

I was thinking of a primer button in the cockpit for some start-up juice and have the oil pressure switch drive a relay to power the pump. I could go a week without driving the X and would'nt want to solely rely on the fuel in the floats...but I would be very interested in your solution, Bob.

I have an electric pump feeding my carb and at cold start-up, I can hear it run hard for 2 or three seconds until it quiets down with back pressure (I have an overflow line from the carb to the tank).

I was thinking of a primer button in the cockpit for some start-up juice and have the oil pressure switch drive a relay to power the pump. I could go a week without driving the X and would'nt want to solely rely on the fuel in the floats...but I would be very interested in your solution, Bob.

Copy the Scorpion system (X similar I think)

The fuel pump circuit for the Scorpion (X is similar I think) uses two relays. One powers the pump during cranking of the starter. The other powers the pump when the oil pressure light is off. In this way starting is easy and the pump has the emergency shut-off if you crash.

The relays are simple; a regular one for the start relay and a switching relay for the run relay. The run relay switch circuit is grounded at the oil pressure light.

The fuel pump circuit for the Scorpion (X is similar I think) uses two relays. One powers the pump during cranking of the starter. The other powers the pump when the oil pressure light is off. In this way starting is easy and the pump has the emergency shut-off if you crash.

The relays are simple; a regular one for the start relay and a switching relay for the run relay. The run relay switch circuit is grounded at the oil pressure light.

sdlsaginaw

Steven Lawson

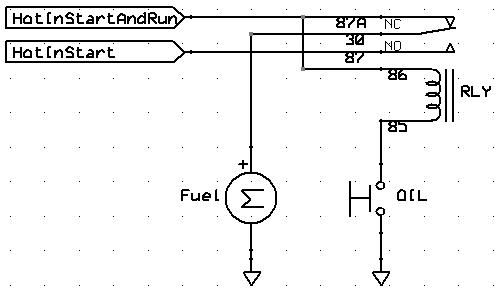

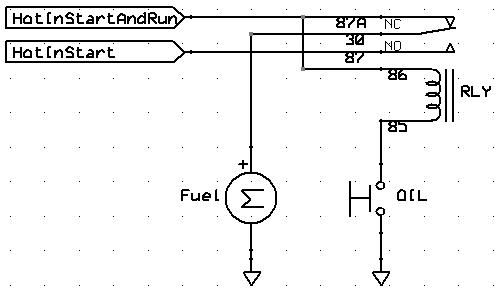

One single pole double throw relay. Coil ground to oil pressure switch. Other coil wire and normally open pin to "hot in start and run". Normally closed pin to "hot in start".

In this case, no oil pressure and cranking will power the pump via the "hot in start" line. Upon building oil pressure the relay will switch the pump over to "hot in start and run" and continue running. If the engine stops in a crash it loses oil pressure, relay switches back to "hot in start" but since you're not cranking the pump stops.

In this case, no oil pressure and cranking will power the pump via the "hot in start" line. Upon building oil pressure the relay will switch the pump over to "hot in start and run" and continue running. If the engine stops in a crash it loses oil pressure, relay switches back to "hot in start" but since you're not cranking the pump stops.

I have it wired to just the ignition switch how would I connect it to the oil light press. switch for safety?

thanks

Chris

See you in Oregon?

sdlsaginaw

Steven Lawson

nope

It has to be "hot in start and run" or the fuel pump will cut back over to the "hot in start" feed when you stop cranking. Basically the oil sensor fully controls whether the pump gets its power from "hot in start" or "hot in start and run"

BTW - the relay wiper powers the pump.

It has to be "hot in start and run" or the fuel pump will cut back over to the "hot in start" feed when you stop cranking. Basically the oil sensor fully controls whether the pump gets its power from "hot in start" or "hot in start and run"

BTW - the relay wiper powers the pump.

Steve, I think you meant to say; "Other coil wire and normally open pin to "hot in start". Normally closed pin to "hot in run".

This works as you intended.

CandBMotorworks

C&BMotorworks

There is a thread on this

I borrowed another member's scheme with a dual relay design. One relay turns the pump on when the key is turned to the start position, so fuel is delivered to the carb during start up before the oil pressure has come up. This avoids the problem where there is no pump because no oil pressure AND the carb bowl has no gas. The second relay runs the pump when the engine is operating and the ignition is in the on position. It's hard for me to hunt for the schematic from my blackberry but I'll try to add the link later if noone else does.

I borrowed another member's scheme with a dual relay design. One relay turns the pump on when the key is turned to the start position, so fuel is delivered to the carb during start up before the oil pressure has come up. This avoids the problem where there is no pump because no oil pressure AND the carb bowl has no gas. The second relay runs the pump when the engine is operating and the ignition is in the on position. It's hard for me to hunt for the schematic from my blackberry but I'll try to add the link later if noone else does.

ng_randolph

Bjorn H

This thread, perhaps? Steven's (sdlsaginaw's) circuit is more elegant, accomplishing the same with a single relay.

sdlsaginaw

Steven Lawson

Schematic

Here's the schematic...

Here's the schematic...

Last edited:

CandBMotorworks

C&BMotorworks

Well that was my thread...

ng_randolph: Kudos.

Kudos.

Anyway, I got mine working rather well. Thanks.

Steven's is certainly simpler. I bought the 5 post relays, so it seems like I've got a bit of overkill and could potentially eliminate one. But since my system works, I'm not inclined to redo it for elegance and possibly introduce another day of frustration. Call it the "if it ain't broke, don't fix it" plan.

Not being an expert on electronics, I usually have to think these things through quite a bit. So, pardon me for "talking" through it:

First, during engine operation the oil pressure sender is normally "open" (i.e., no ground), so that the light in the dash does not come on while there is oil pressure. That being the case, the relay would only switch to 87 if there was a loss of pressure.

The start circuit is connected to post 87 and when you turn the key to the start position, the switch is turned on because the oil pressure sender is grounded to light the dash light because there is no oil pressure. So, power is sent to the pump.

When you release the key from "start", the engine is running, there is oil pressure, the switch turns off (a good thing so that the relay isn't always running hot) and the power to the pump comes from the 87a ignition 'on' circuit. But only so long as there is oil pressure. If there is a loss of oil pressure, then the switch turns on and, because the key is not in the "start" position, there is no power and the pump shuts off.

Nice.

ng_randolph:

Anyway, I got mine working rather well. Thanks.

Steven's is certainly simpler. I bought the 5 post relays, so it seems like I've got a bit of overkill and could potentially eliminate one. But since my system works, I'm not inclined to redo it for elegance and possibly introduce another day of frustration. Call it the "if it ain't broke, don't fix it" plan.

Not being an expert on electronics, I usually have to think these things through quite a bit. So, pardon me for "talking" through it:

First, during engine operation the oil pressure sender is normally "open" (i.e., no ground), so that the light in the dash does not come on while there is oil pressure. That being the case, the relay would only switch to 87 if there was a loss of pressure.

The start circuit is connected to post 87 and when you turn the key to the start position, the switch is turned on because the oil pressure sender is grounded to light the dash light because there is no oil pressure. So, power is sent to the pump.

When you release the key from "start", the engine is running, there is oil pressure, the switch turns off (a good thing so that the relay isn't always running hot) and the power to the pump comes from the 87a ignition 'on' circuit. But only so long as there is oil pressure. If there is a loss of oil pressure, then the switch turns on and, because the key is not in the "start" position, there is no power and the pump shuts off.

Nice.

ng_randolph

Bjorn H

That would work if the oil pressure switch was closed when there was oil pressure, open with no oil pressure. The stock pressure switch works the other way around. Closed to turn on the warning light with no oil pressure, open to leave the light off once there is sufficient pressure.

Last edited:

sdlsaginaw

Steven Lawson

Whoops

Forgot the oil switch is backwards. Duh! I'll redraw.

Ok. schematic updated for normally closed oil switch.

Forgot the oil switch is backwards. Duh! I'll redraw.

Ok. schematic updated for normally closed oil switch.

Last edited: