You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine Test Stand and Rebuild Project

- Thread starter davejake

- Start date

Dr.Jeff

True Classic

I recall some discussion about this several years ago. There were a few designs described (including the use of the engine bay structure from a parts car). Unfortunately I don't have a link to that thread. Then there was a related thread that discussed engine storage stands (vs test stands). But those were mostly wood supports attached to a furniture dolly. Although something like that might work? I've test run engines just sitting on the floor with the cherry picker attached to the top of it, to keep it from flopping over.

Looking at the pics you posted, the first one seems very overkill but I like the second one. Any more pics of it?

Looking at the pics you posted, the first one seems very overkill but I like the second one. Any more pics of it?

dllubin

Don

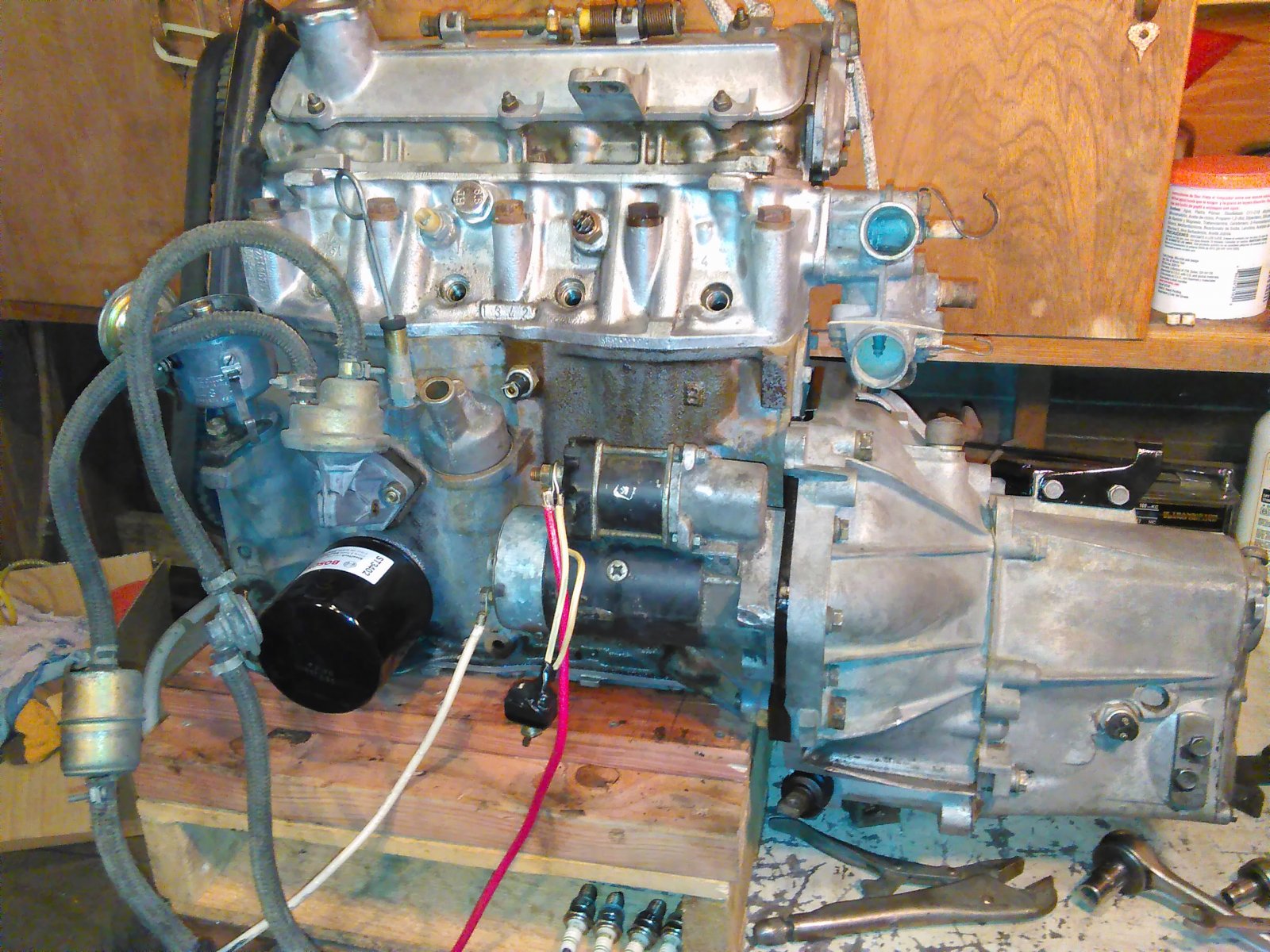

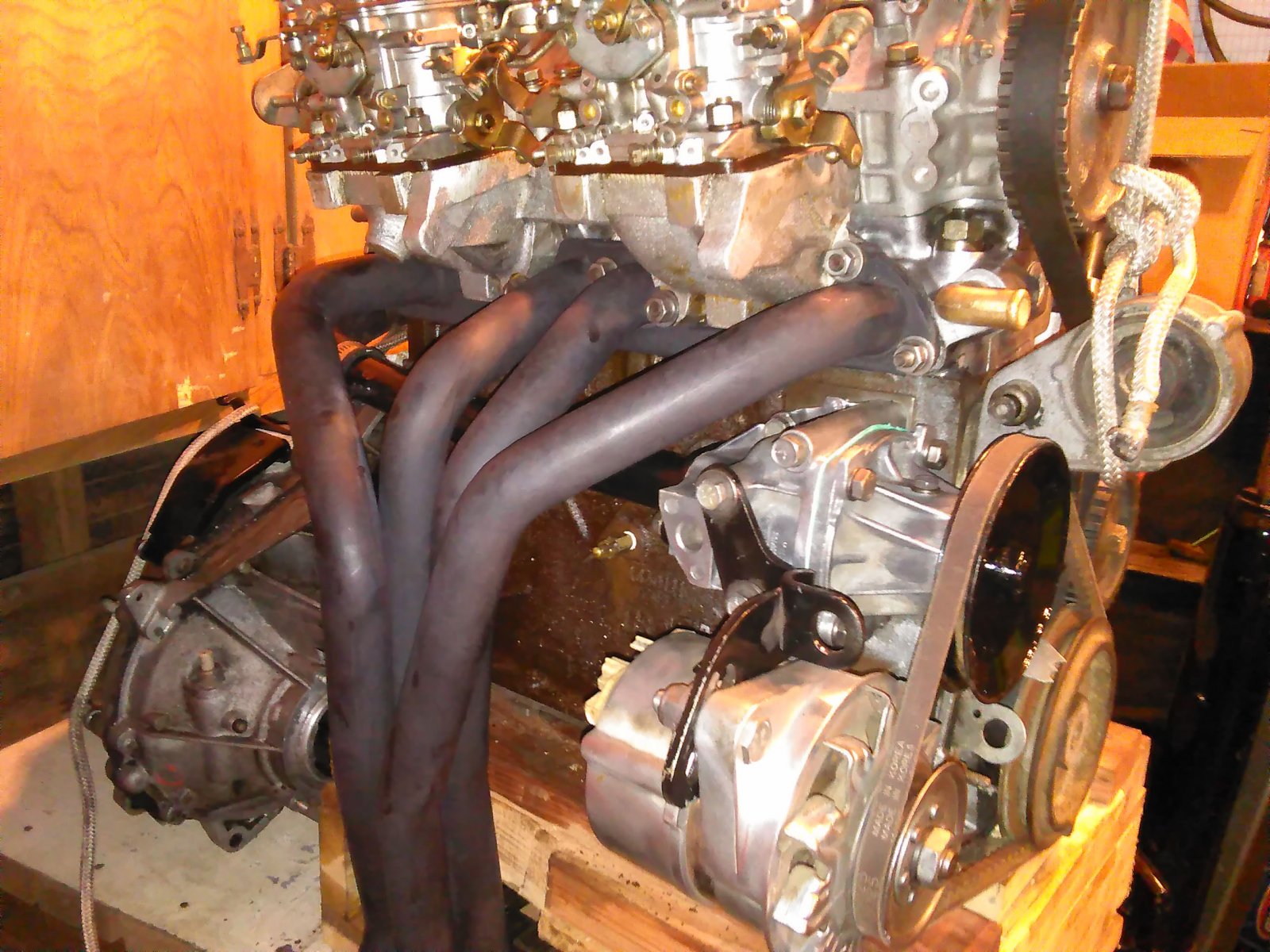

I used an engine stand that 7982X made to ship me an engine. It was shaped to contact the engine along the periphery of the oil pan (or block if no pan present).

I modified it to use as an engine run stand by trimming it enough to accommodate the transaxle and the headers.

After I put the motor in the car, I added wheels to it for storing the old engine in the basement.

I modified it to use as an engine run stand by trimming it enough to accommodate the transaxle and the headers.

After I put the motor in the car, I added wheels to it for storing the old engine in the basement.

Attachments

Dr.Jeff

True Classic

I found the older thread I referenced earlier, plus a couple others.

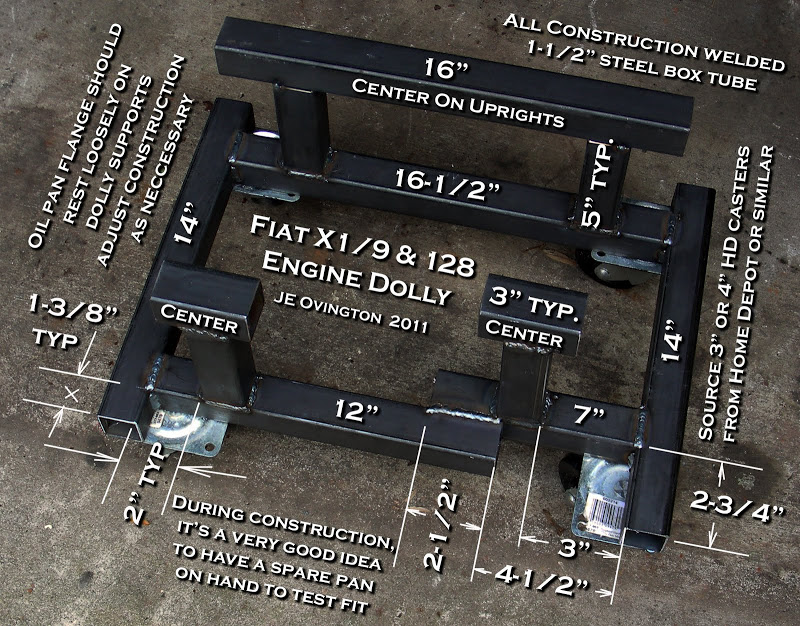

This one is more about "storage stands", but it has a nice illustration with the dimensions for a robust stand. That could easily be modified into a test run stand:

This thread sounds like it had some good info but all of the pics and links are dead, so not a lot of good stuff left to see:

Here is a thread with a video of someone using their heavy duty test stand:

And here is a mix of info, including some of the same stuff repeated. But a good read:

A few of my favorite pics from all of those threads...

This one is more about "storage stands", but it has a nice illustration with the dimensions for a robust stand. That could easily be modified into a test run stand:

anyone here ever build an engine cradle?

Has anyone here ever built an engine cradle? I obviously can't find ones for sale, so I need to make one. any pictures?

xwebforums.com

This thread sounds like it had some good info but all of the pics and links are dead, so not a lot of good stuff left to see:

Here is a thread with a video of someone using their heavy duty test stand:

And here is a mix of info, including some of the same stuff repeated. But a good read:

Engine Stand for X1/9 1300?

My 1300 engine which has been at the race shop for the last 10 months is now finished! But of course my X is not ready for the installation so is there an engine stand that fellow forum members use and recommend? The 1300 is fully assembled from the IDF's to the pan including the transmission.

xwebforums.com

A few of my favorite pics from all of those threads...

Dr.Jeff

True Classic

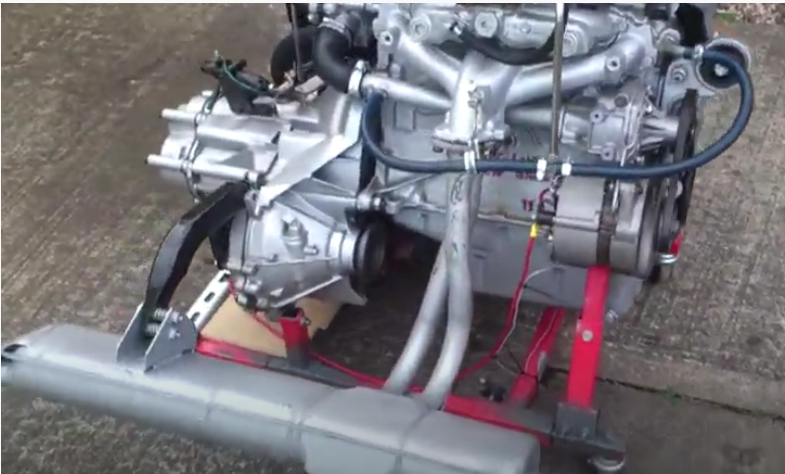

There are two basic approaches that I like, and I'm not sure which one I'd do. Both are similar in that they start with a square-shaped tube frame on wheels, then built up from there. The difference is one has braces extending up to the most convenient bolt hole locations around the lower aspects of the engine/trans, while the other replicates the stock X1/9 engine mounts. The first two pics I posted above are examples of the first approach (although the blue one is a Honda engine). The last picture I posted is an example of the second approach - although I don't think it needs to be nearly this robust...I'd only use the bottom frame with an extension in the front for the snail mount and another extension for the dog bone. So without all the other framework, and the tubes would be much smaller to keep it light and compact. That way it can also be used as a storage stand.

Dr.Jeff

True Classic

Here's a question. Would you want it with a radiator/cooling system, full fuel system, gauges, etc, so you can run it for extended periods? That would be a nice way to tune it, perform the heat cycles for a head retorque, check for leaks after getting to full operating temp, etc. Therefore the stand will need to be a little larger to accommodate these extra things.

davejake

3 is company too!

Yes, definitely thinking of building something to run and tune an engine for an extended period of time. Especially now that I have aquired 4 engines this year! I have some work to do!!!Here's a question. Would you want it with a radiator/cooling system, full fuel system, gauges, etc, so you can run it for extended periods? That would be a nice way to tune it, perform the heat cycles for a head retorque, check for leaks after getting to full operating temp, etc. Therefore the stand will need to be a little larger to accommodate these extra things.

PaulD

Paul Davock

Here's a question. Would you want it with a radiator/cooling system, full fuel system, gauges, etc, so you can run it for extended periods? That would be a nice way to tune it, perform the heat cycles for a head retorque, check for leaks after getting to full operating temp, etc. Therefore the stand will need to be a little larger to accommodate these extra things.

If space is not an issue, see the Redline rebuilds test stand.

check 15 minutes in.

Dr.Jeff

True Classic

That's the trade off; the size of the stand can get quite large by the time you add several features to it. So depending on how often you will actually use it, it may become more of a storage issue than it is worth. In one of those threads I referenced someone suggested to just drop the engine into the car to do all of your testing. In many cases that may be more practical (although it would be nice to work on it completely exposed). I've debated if it might be better to build an improved engine/trans installation rig than a test stand. In other words make it much easier to get the powertrain in and out of the car; my current method works but isn't great.If space is not an issue

MikeHynes

True Classic

I use a "stand" very much like the one Don built (above) to remove and install the drivetrain. I like having unfettered access to everything when I'm building the drivetrain. It's a lot easier to be able to lift the chassis up and roll the drivetrain in and out, than to try to wrangle it around under the car. And it's just easier to fit everything, especially the manifolds, before its installed.

I don't recommend that you start the engine when it's mounted like that, but I do turn it over with the starter before I install it to make sure everything is Oaky Doaky before it goes in.

I need to get off my duff and build an engine run-in stand!

I don't recommend that you start the engine when it's mounted like that, but I do turn it over with the starter before I install it to make sure everything is Oaky Doaky before it goes in.

I need to get off my duff and build an engine run-in stand!

Dr.Jeff

True Classic

Same here. What I need to improve is the way I lift the car to get the drivetrain/roller-cart under it. I've been using a cherry picker but it gets in the way. I need to build a frame for my hoist so I can lift it from above.I use a "stand" very much like the one Don built (above) to remove and install the drivetrain.

However I'm also considering adapting a "lifting" mechanism to raise/lower the engine from underneath. Maybe something like I described here:

Engine Stand for X1/9 1300?

On the subject of engine stands and equipment to remove/install them, I've been thinking about adapting another item I have. It is a motorcycle lift jack, like this... If a engine cradle (similar to the ones discussed earlier in this thread) could be attached to the top of this, the engine...

xwebforums.com

Dr.Jeff

True Classic

Regarding the amount of space a full testing stand takes up. Perhaps a removable attachment could be made to add to an existing "storage stand". Something that holds the extra components (for cooling, fuel, etc), and can easily be added when doing engine running, but removed and when only using the stand for storage. At least that way they are separate components and easier to make room for.

dllubin

Don

I found my stand was stable enough to run the engine long enough (~20-30 sec) to confirm it was worth trying in the car. The first time I did it, I had it connected to an engine crane on top just in case it was not stable. It turned out not to be an issue. I thought about connecting it to water but really did not have a need to run it that long.

Video: Engine running on stand

Video: Engine running on stand

MikeHynes

True Classic

It looks like the stand that Jon built might accommodate a SOHC engine too. But the front of the SOHC engine would be at the other end. Makes sense as the rad hoses would be at opposite ends of the two engines. And, there looks to be a bar up high to mount the dog bone engine mount as well. Also looks like it's wide enough to mount the lower crossmember too.does anyone have a design to build an Engine Test Stand for an X1/9 1500 engine? Like Jon Logan built?

View attachment 39741

Maybe you already have a pic of and engine test stand that will work with a SOHC engine? (And the DOHC too.)

It would also make sense to use a Spider radiator in such a dual purpose engine stand, especially if you had a spare, the Spider comes stock with an electric fan. You wouldn't need the entire trans either, just the bellhousing to mount the starter and lower motor mount.

To me it makes sense to leave as much room as possible to access the engine. And, from what I have seen you don't need a lot of support to keep it from flopping over when it revs.

Dr.Jeff

True Classic

I like your idea of making it break down. I was looking at a few examples online and I think it could be "modular". With the basic engine stand being the base and a attachable second module for the radiator, fuel tank/pump, battery/ignition, control panel, etc, all on one "bolt on" frame. The base could be similar to something like that Honda one or the Fiat one you showed earlier, including the transmission:I think we are going to build something like this. Perhaps even bolt the base together so it can be broken down when not in use:

View attachment 39805

This can be used as a storage or work stand when the extra module is removed. Then just bolt on the second upright frame to make it a test run stand. The extra module could be along these lines, made to easily attach to the base frame:

With all of the needed items to enable running the engine on one frame it is easy to change it over. And being two modular components would make storage much easier.

Now you've got me thinking about this for myself. I build different engines from various makes of vehicles. So I'd make the base engine stand a simple square frame with individual "bolt on" attachments to mount each type of engine I work on, therefore it's "convertible". And the add-on engine run module would work for any of them.

So it would look a bit like this; the red square is the basic base, the interchangeable black uprights are designed for each type of engine, and the removable square frame on the end would have everything needed to run the engines (more than shown here):

Last edited:

Dr.Jeff

True Classic

That's exactly how I do it. Most of my DIY projects are made from scraps that I have laying around or from the "remnants" pile at the metal yard. And my designs usually change as I progress through them.@Dr.Jeff yes, this is the direction we are headed! We have a local metal supply shop that sells "odds & ends" at a discount, so I think my son & I will head there in the coming weeks. This will mostly likely be another of our Design on the Fly projects!

You may just talk me into doing this also.

If I make one I don't think I'd try to create an elaborate control panel. Things like oil pressure and coolant temp can be checked with simple mechanical gauges connected directly to the engine via short hoses. The RPM's can be monitored with a typical "Tach/Dwell" meter clipped onto a plug wire. The battery can be connected from the car by jumper cables. A spare fuel pump stuck into a common 5-gallon "jerry" can of gas. Plus a toggle switch to feed 12V to the coil, ECU, etc. That's all I'd need.

PaulD

Paul Davock

If I make one I don't think I'd try to create an elaborate control panel. Things like oil pressure and coolant temp can be checked with simple mechanical gauges connected directly to the engine via short hoses. The RPM's can be monitored with a typical "Tach/Dwell" meter clipped onto a plug wire.

For a fresh engine, I would want the gauges to be where I could see them all at once. I would want to see the oil pressure immediately, and if there was a new cam, keep it between 2000 and 2500 RPM for 20 minutes to break it in. It could be difficult if I had to move about the engine to take all of the readings. A helper would make this possible though.