Wow, did not expect such a response

I will answer the questions or provide comments:

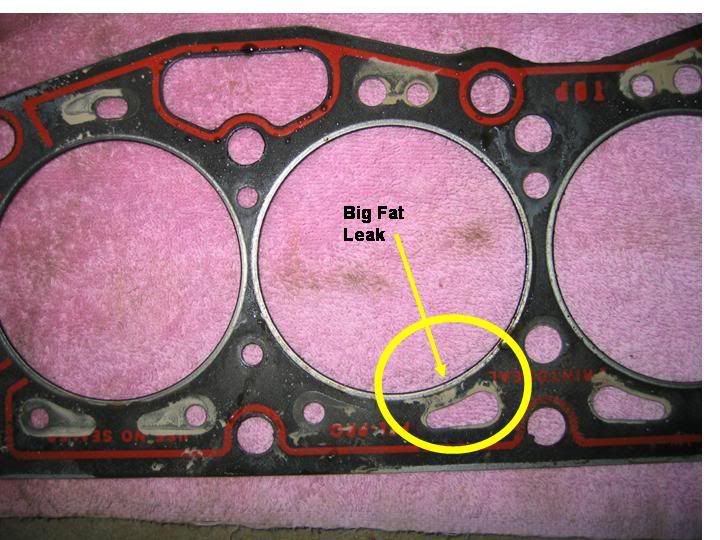

1) Yes it was retorqued, the first felpro I used failed quickly but was not however retorqued, called a friend at Federal Mogul and he said definitely they need to be retorqued, more of a marketing gimmick for service guys

2) The head was milled a couple of years back to bump my compression to 10.55/1 I am confident it is flat, it has less than 500 miles on it in fact this is the gasket installed for that mod.

3) The block may not be perfect, never have taken a cut from it and certainly could be a contributor (the failure is worse on the head side though - hmmm)

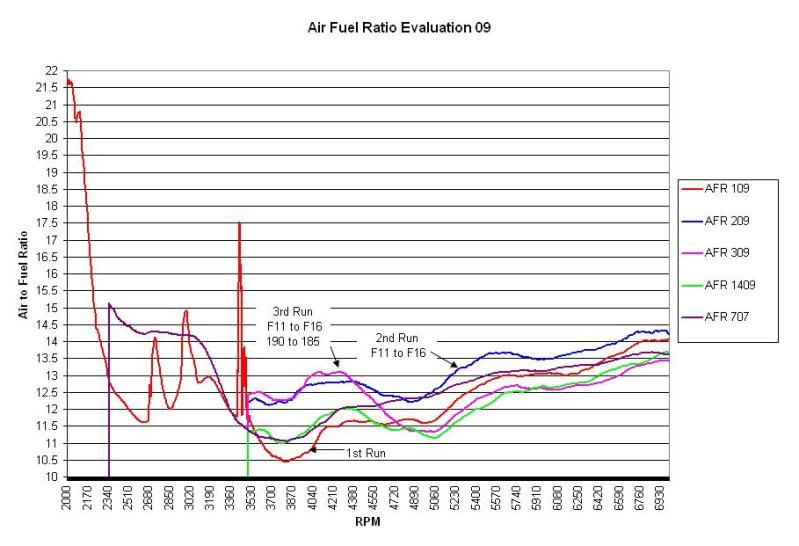

4) Lean condition, not very likely. I have a rich running condition I can't seem to get just right.

5) The bore is stock, never machined. If the gasket overhangs the bore then it is certainly NFG.

5) I have had this engine together for 18yrs now and modified when I wanted to try something new. I have never had a stock gasket fail but the two Blowpros (yes I find that funny - and accurate) failed - you do the math

6) Timing is a possibility however full advance is 36-38deg and the ramp up profile is the same as FI dist- nothing alarming there

I got a crack up at some of the responses. Frankly no one really knows what the failure mode was. Is is heat, cyclic fatigue, or a pressing defect? No one really knows. The point of posting this information is to inform folks of a problem I had with these gaskets. Volunteering a prognosis is your prerogative so have at it, seems that was a popular trend recently with Armageddon end of the world etc- you get the drift. For those who are contemplating a head gasket replacement I suggest you use stock. I think Paul summed it up very well. For my engine there could be reason for speculation but his, hmmmm not really.