So, a little update on my exhaust journey. I had been playing with one of the exhaust inserts from Car Chemistry and had modified it to be able to insert it just downstream from my V clamp connection. I had secured it with a small bolt through the exhaust pipe. I felt it had made an improvement in the exhaust loudness, but after a couple of more drives to sort out some suspension issues, I noticed a rattling coming from the exhaust around 3,000 RPM. I assumed that the insert was causing the rattle, so I dropped the exhaust to take a look and found that the insert was no longer where it was supposed to be....

I snaked a camera down the exhaust and found it laying in the catalytic converter where it had actually damaged some of the honeycomb. It also looked kind of melted! I tried to shake it back out, but it was not coming. I thought I could maybe get it with one of those pickup tools that have the little claw fingers on the end. So I tried to work it around the bend and through the flex coupling, but then one of claws snagged on the flex mesh. Now it wouldn't go further and I couldn't pull it back out either. Crap!!!!

At this point, I was max frustrated and didn't see much of a way out so I cut the exhaust between the cat and the coupler and hoped I would be able to weld it back together. I freed the claw of the tool and fished out the insert from the cat.

I was pretty amazed that it looked like that. I am not sure if it got deformed like that from the heat coming from the header or if it was a result of being next to the honeycomb of the cat. I don't think it could have gotten around the bend and through the flex coupler in it's original configuration, so I assume it happened before it let go. Either way, it was a disaster.

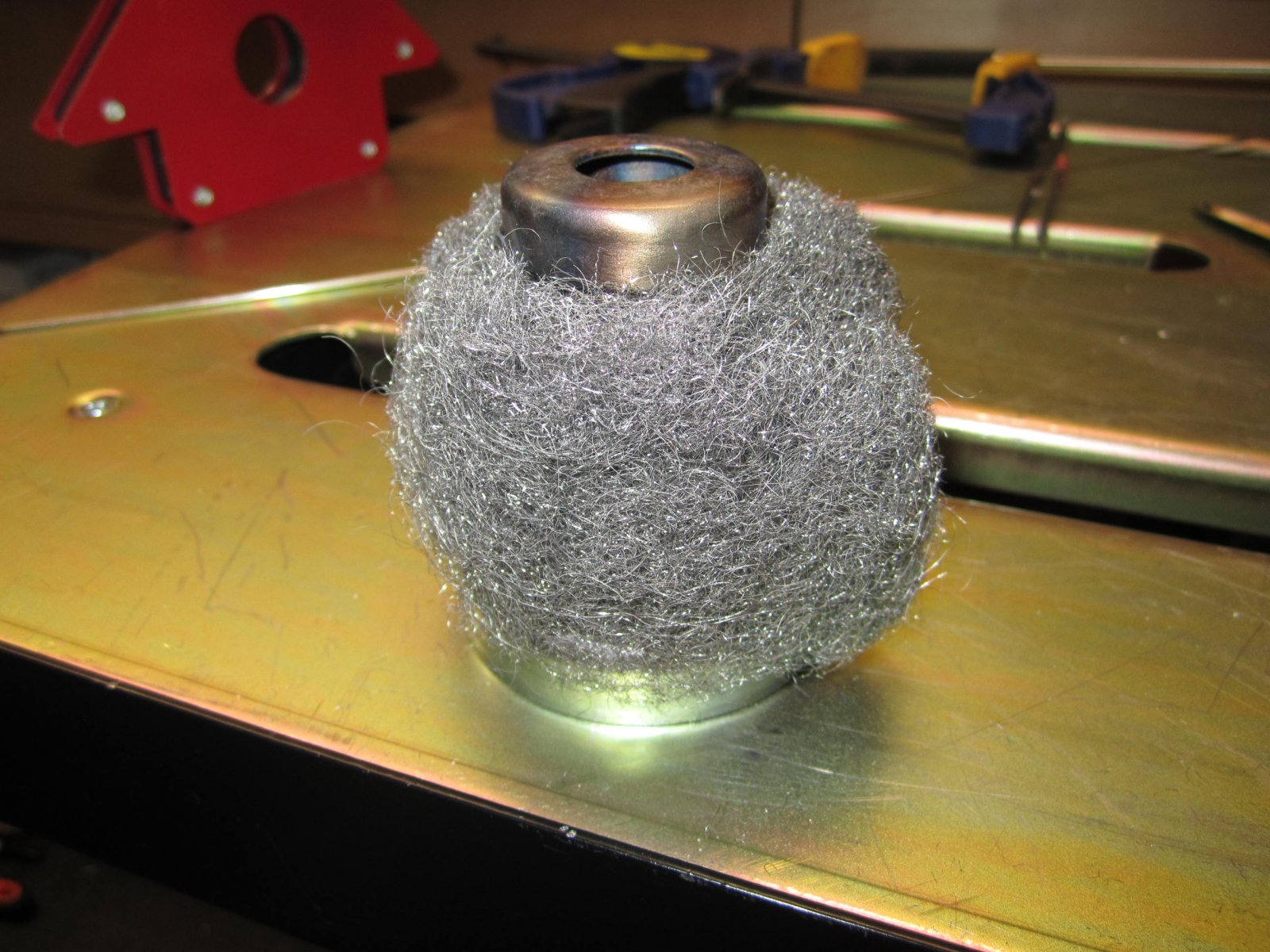

I was able to get the exhaust put back together although getting to the joint directly below the muffler was really hard to reach with the TiG torch. Not the prettiest weld but I got it done and back in. I still wanted to quiet down the exhaust so I took the remaining piece of the insert that I had cut off that had one ring on it. I tack welded a small cap that Car Chemistry says you can use to tone down the exhaust and then wrapped the insert with stainless steel wool from Car Chemistry. I was not about to put it where I tried it before, so I put it inside the tailpipe. I had also changed the exhaust tip to the same one that Hussein used, but rather than weld it on, I bolted it on with two Allen head stainless bolts. That way, I could remove it to get access to the insert if I wanted to take it out or change the steel wool as it degrades over time. I took it out for drive today and was quite happy with the new sound.

My motto for this whole build project has been "Live and learn". Another self-inflected lesson in automotive artistry under my belt.