lookforjoe

True Classic

EDIT - Gen2 is entirely different than Gen1 shown in this post (link to later post)

I'm in the process of parts gathering for an AWD conversion on my Volvo C30. This was something I was considering down the road, however, a mint condition (besides the fact they just rolled it ) S40 AWD has come up, so that will be the donor for all the drivetrain parts I need, besides the manual AWD trans.

Anyhow, a major concern with the conversion is the Haldex controller. Some people have had success using a newer gen controller (3, vs. 2 that came with the S40/V50), others no so much. A work around that VW guys have developed is a manual controller. I need help with aspects of building the controller, and I know we have some tech-savy guys on here, I just don't recall who.

I can't post a link to the thread as it is closed/paid members only. I've added a screenshot of the post description of the Arduino/controller circuitry and a basic schematic.

I have no clue how to compile code, or how or where to load it, and they don't explain any of that - presumably assumption is one already knows that stuff. No one is active on that forum currently, so no one has replied to any of my requests for directions or clarification.

The wiring diagram is incomplete, and I can't tell for example how the stepper motor wiring ties into the Arduino via the PCB, since no connections are illustrated.

Three primary components are:

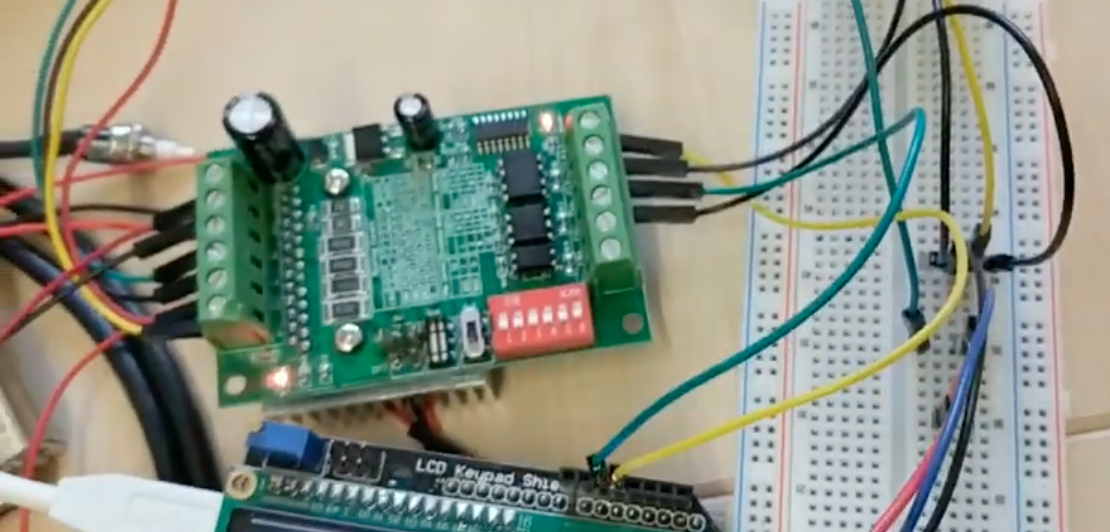

Arduino Uno, TB6560 3A, J204a display

So, any help on basic directions for compiling/loading code, and thoughts on what makes sense regarding the actual control inputs from the PCB shown to the actual stepper motor.

Video of one being tested here:

and alternate here:

Thanks in advance for any input!

Schematic doesn't show TB6560 ?

EDIT: Found this link for wiring Arduino to stepper controller

https://tronixlabs.com.au/news/tutorial-l298n-dual-motor-controller-module-2a-and-arduino/

and this, probably more useful, but I don't have stepper pin out

https://www.instructables.com/id/ARDUINO-UNO-TB6560-Stepper-motor-driver/

TB6560 Connection to arduino

pin 9 (Step pin) to CLK+,

pin 8 (Dir pin) to CW+,

CLK- and CW- connect to GND arduino.

Do not connect EN+ and EN- to any ARDUINO PIN.

Stepper motor connection, you need to know which color is A+, A-, B+ and B-, according to the stepper motor spec. sheet.

I'm in the process of parts gathering for an AWD conversion on my Volvo C30. This was something I was considering down the road, however, a mint condition (besides the fact they just rolled it ) S40 AWD has come up, so that will be the donor for all the drivetrain parts I need, besides the manual AWD trans.

Anyhow, a major concern with the conversion is the Haldex controller. Some people have had success using a newer gen controller (3, vs. 2 that came with the S40/V50), others no so much. A work around that VW guys have developed is a manual controller. I need help with aspects of building the controller, and I know we have some tech-savy guys on here, I just don't recall who.

I can't post a link to the thread as it is closed/paid members only. I've added a screenshot of the post description of the Arduino/controller circuitry and a basic schematic.

I have no clue how to compile code, or how or where to load it, and they don't explain any of that - presumably assumption is one already knows that stuff. No one is active on that forum currently, so no one has replied to any of my requests for directions or clarification.

The wiring diagram is incomplete, and I can't tell for example how the stepper motor wiring ties into the Arduino via the PCB, since no connections are illustrated.

Three primary components are:

Arduino Uno, TB6560 3A, J204a display

So, any help on basic directions for compiling/loading code, and thoughts on what makes sense regarding the actual control inputs from the PCB shown to the actual stepper motor.

Video of one being tested here:

and alternate here:

Thanks in advance for any input!

Schematic doesn't show TB6560 ?

EDIT: Found this link for wiring Arduino to stepper controller

https://tronixlabs.com.au/news/tutorial-l298n-dual-motor-controller-module-2a-and-arduino/

and this, probably more useful, but I don't have stepper pin out

https://www.instructables.com/id/ARDUINO-UNO-TB6560-Stepper-motor-driver/

TB6560 Connection to arduino

pin 9 (Step pin) to CLK+,

pin 8 (Dir pin) to CW+,

CLK- and CW- connect to GND arduino.

Do not connect EN+ and EN- to any ARDUINO PIN.

Stepper motor connection, you need to know which color is A+, A-, B+ and B-, according to the stepper motor spec. sheet.

Last edited: