Steve Hoelscher

True Classic

I figured I should probably post this as a public service message. Especially with consideration that I have seen two of these instances in the last few months. And given that this is a known failure that I have been preaching about for more than a couple of decades...

Please don't try to roll start your X1/9 (or any car for that matter) in reverse. Or maybe I shouldn't post this because it would reduce my transmission business

So I tore down a customer core the other evening in preparation for another build. I knew the transmission had a tooth broken off reverse, likely from trying to bump start the car in reverse. But there is no way to know the extent of the damage. I was pretty sure that the input shaft was the one with the missing tooth due to the frequency of the "bang" when backing up.

And to deter you from thinking this is something you might get away with once in an emergency let me advise you that you certainly won't and the results are pretty catastrophic.

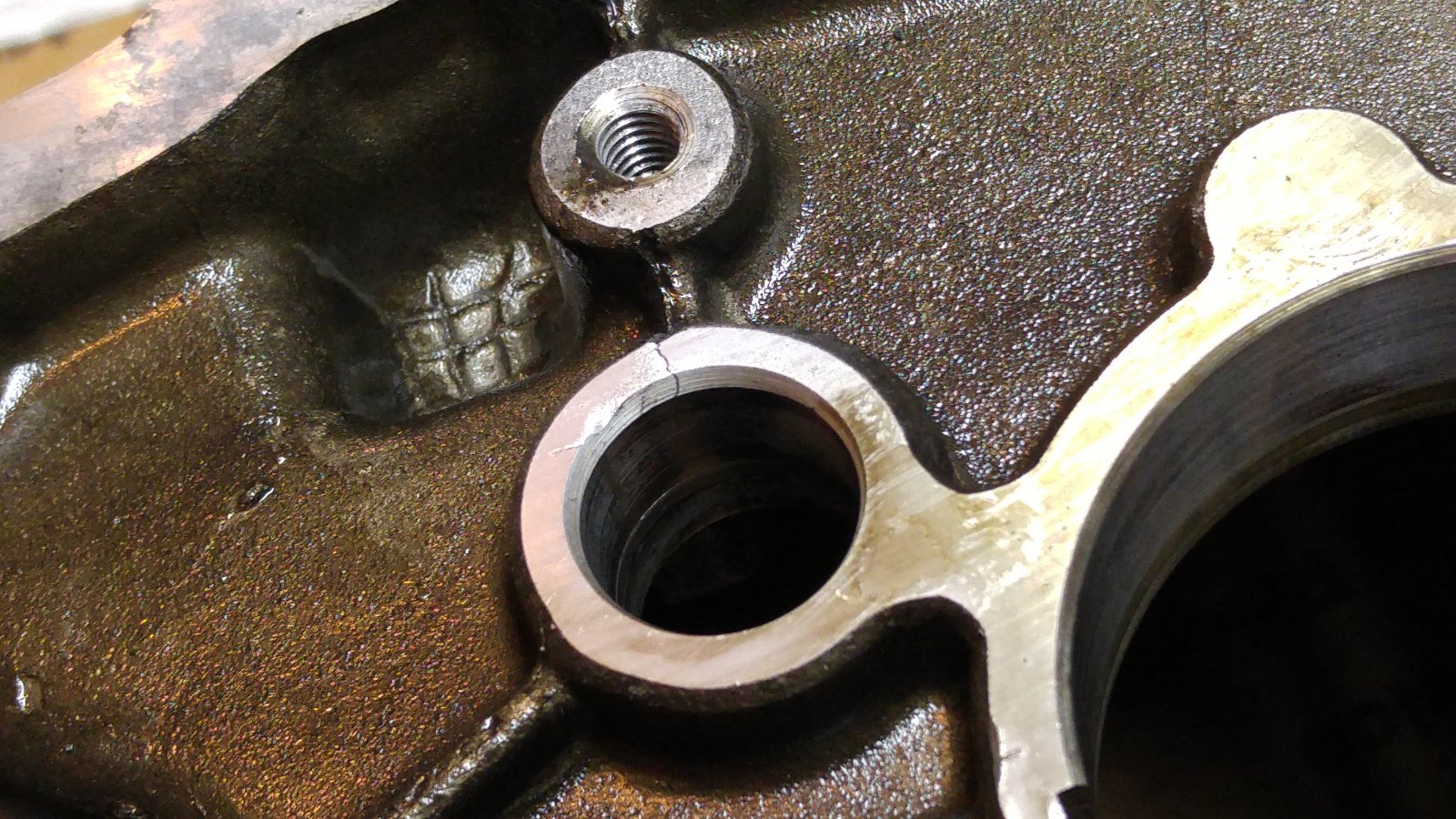

This is the input shaft. The missing tooth was attached to the magnet.

The reverse gear on the input shaft is machined into the shaft. There is no way to replace or repair the shaft. The otherwise perfect input shaft is now expensive scrap metal.

Of course the missing tooth and the bang you hear when backing spread its cancer to the reverse idler gear and the 1-2 slider. Both of which are also now scrap.

As is a typical of this kind of damage the reverse idler shaft was bent, which is also destined for the scrap pile. You can see the contact point at each end of the shaft and the gap down the side of the straight edge. This is a 14mm ('81-'82) transmission.

I often find the reverse idler shafts bent in transmissions with recent rebuilds and completely shredded reverse gears. Because the person doing the rebuild didn't know to check to see if the shaft was true and if not replace it. The bent shaft then substantially weakens reverse and thus shreds the new parts in very short order.

So this transmission needs; an input shaft, a reverse idler gear and shaft and a 1-2 slider. That's about $500 in parts before I even get to the gear stack, that will likely need a gear or two, a set of synchros, a 3-4 slider and at least a couple of shift forks. But we're not through yet. When that shaft bent the end with the o-ring sits in a boss in the aluminum case. That case boss will not accommodate the bending of the shaft. So the boss is cracked and the case is now scrap.

It is important to note that when evaluating one of these transmissions for rebuild there are 5 major "components" that are necessary; the case, the input shaft, the gear stack, the diff and the shift rails/forks. Diffs and shift rails/linkages are not usually damaged and I have lots of spares/parts for these when they are. Gear stacks are wear items and replacing components there is just part of a typical rebuild. So when evaluating a core for rebuild the for my purposes the critical components are: The case, the input shaft, gear stack. In this case the case and input shaft are unuseable. As is a major component in the gear stack (the 1-2 slider) and the reverse idler. Basically, the core is 75% scrap and it would cost less to buy another core than to buy the replacement parts.

So keep that in mind the next time you select reverse in your X. You'll save us both a lot of headache.

Please don't try to roll start your X1/9 (or any car for that matter) in reverse. Or maybe I shouldn't post this because it would reduce my transmission business

So I tore down a customer core the other evening in preparation for another build. I knew the transmission had a tooth broken off reverse, likely from trying to bump start the car in reverse. But there is no way to know the extent of the damage. I was pretty sure that the input shaft was the one with the missing tooth due to the frequency of the "bang" when backing up.

And to deter you from thinking this is something you might get away with once in an emergency let me advise you that you certainly won't and the results are pretty catastrophic.

This is the input shaft. The missing tooth was attached to the magnet.

The reverse gear on the input shaft is machined into the shaft. There is no way to replace or repair the shaft. The otherwise perfect input shaft is now expensive scrap metal.

Of course the missing tooth and the bang you hear when backing spread its cancer to the reverse idler gear and the 1-2 slider. Both of which are also now scrap.

As is a typical of this kind of damage the reverse idler shaft was bent, which is also destined for the scrap pile. You can see the contact point at each end of the shaft and the gap down the side of the straight edge. This is a 14mm ('81-'82) transmission.

I often find the reverse idler shafts bent in transmissions with recent rebuilds and completely shredded reverse gears. Because the person doing the rebuild didn't know to check to see if the shaft was true and if not replace it. The bent shaft then substantially weakens reverse and thus shreds the new parts in very short order.

So this transmission needs; an input shaft, a reverse idler gear and shaft and a 1-2 slider. That's about $500 in parts before I even get to the gear stack, that will likely need a gear or two, a set of synchros, a 3-4 slider and at least a couple of shift forks. But we're not through yet. When that shaft bent the end with the o-ring sits in a boss in the aluminum case. That case boss will not accommodate the bending of the shaft. So the boss is cracked and the case is now scrap.

It is important to note that when evaluating one of these transmissions for rebuild there are 5 major "components" that are necessary; the case, the input shaft, the gear stack, the diff and the shift rails/forks. Diffs and shift rails/linkages are not usually damaged and I have lots of spares/parts for these when they are. Gear stacks are wear items and replacing components there is just part of a typical rebuild. So when evaluating a core for rebuild the for my purposes the critical components are: The case, the input shaft, gear stack. In this case the case and input shaft are unuseable. As is a major component in the gear stack (the 1-2 slider) and the reverse idler. Basically, the core is 75% scrap and it would cost less to buy another core than to buy the replacement parts.

So keep that in mind the next time you select reverse in your X. You'll save us both a lot of headache.

Last edited: