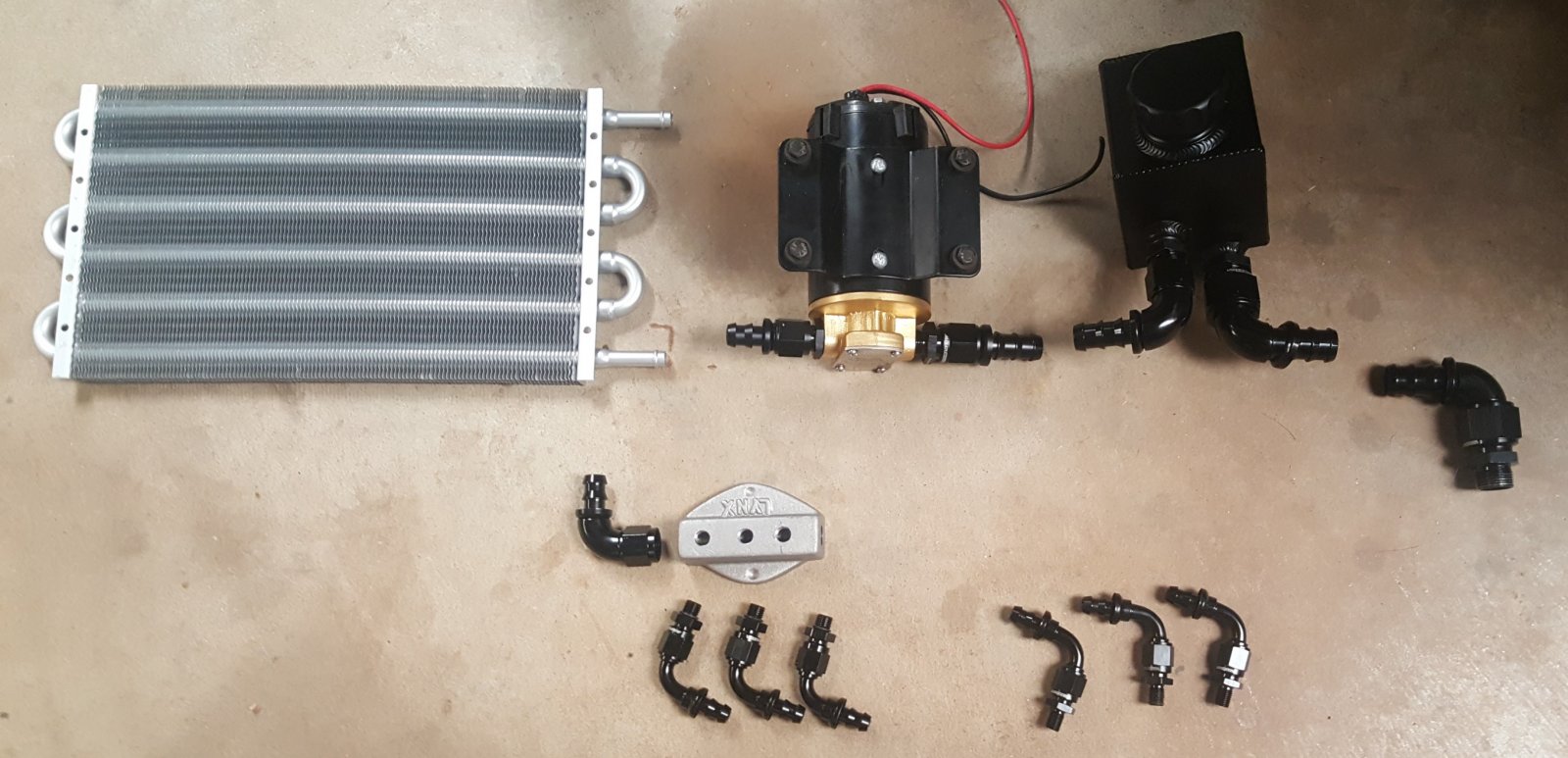

Most of the fittings and parts for the transmission oil cooler system also arrived.

A general schematic layout of the parts

From the transmission oil drain plug (M22 x 1.5 fitting) it's two -12AN 90's (all full flow fittings except the -6) into the generic (chinese) alloy power steering oil reservoir. Two reasons for this... I want to increase the overall capacity of the system, and this adds about 400ml (in total I'm hoping to get almost 4 litre of oil in the system, standard is about 3.2 litres from memory, so about 25% more) plus it acts as a "buffer" for the system. As I've chosen a pump (on price as this is all lemons dollars cost) that isn't able to run 100% of the time, I've designed the system with a variable delay loop timer (I'm thinking 20 seconds on / 20 seconds off cycles) .and because of the constant on/off cycling the system will work much better with a surge reservoir ahead of the pump. it also adds a very easy fill and level check point, the screw on cap is tight fitting with an O ring seal. Where its mounted the level in the tank will be the level in the trans.

Outlet from the buffer tank / inlet to the pump is -10AN, The original fitting in the tank was a tiny m14 x 1.5 ORB barb, and an -10 to M14 fitting has a tiny thru hole, so I enlarged the hole in the tank and tapped it to M16 x 1.6 which has a 11mm thru hole. (the pump has a 11mm thru hole 3/8 bsp to -10 fitting. Such large fitting and lines are needed on the sucton side of the pump to eliminate resistance to flow.

Outlet from the pump to the cooler is -8AN. Not in the picture (still waiting) are the to 1/2 inch to -8 male compression fittings that will slide over the co0ler tubes and with a compression olive secure to them giving a -8AN male fitting on the tube and the straight -8 female hose ends that will thread over them

The three way junction block and fittings are to distribute the cooled oil back into the transmission, 1 x - 8 line in., 3 x -6 lines out

I'm going to drill / tap 3 x 10 x 1,25 holes right above 3 / 4 and 5 gears to flood them with cooled oil from above, rather than just relying on splash lubrication, the discharge hole in the M10 fittings is just over 3mm and will be the flow restrictor. The system (by calculation) should move about 4 litres a minute of running.

hopefully this stops two of the issues these transmissions seem to have when used hard.

3rd gear and 4th gear I have seen sieze the bush to the cluster shaft/inside of the gear, and I've seen 4th and fifth gears competely destroyed. with teeth turned into powdered metal.. both related to lubrication / oil temp issues IMO so this system should (fingers crossed) eliminate these known problems.

The trouble I have is that I have no idea how much heat I need to dissapate from the oil, and no idea (in real terms) what the 14000BTU's of capacity the cooler has "looks" like in terms of degrees of temp dropped per volume of oil, I haven't bothered to work it out... the only real test is testing the car and measuring the oil temps with the sytsem on and off.

If the system doesn't have enough cooling capacity, the option to add a second identical cooler is available.

I could loop them in series, joined with a thermostat to bypass the second cooler if the oils temp is too low (so the oil never gets too cold) as the three way junction/ditribution block has a second inlet at the other end and I already have a suitable thermostat.

edit 24/03/2021

after a few design changes / improvements, this is the final setup going into the lemons racer.

1. pickup from the oil drain plug on the transmission (M22 x 1.5) -10 90 elbow

2. the pump, for the lemon it's budget buy at just under $100aud. can't be run continuously so will cycleon a loop on/off for 20 second, (it's a bit of a gamble if this pump is really suitable for the job, but Im backing it will last the 16 to 20 hours I need it to)

3. a one way check valve to ensure the oil doesn't drain back when the system is turned off

4. the inlet to oil cooler one

5. the oil thermostat. if trans oil temp is under 90C the oil will then exit and go to the oil reservoir tank (8)

6. outlet from oil thermostat

7. outlet from oil cooler two. If the oil temp is more than 90c when it gets to the thermostat it will pass thru oil cooler two

8. the oil reservoir tank, 2 litre capacity

9. inlet to oil reservoir

10. inlet to oil reservoir

11. discharge check valve. this is to stop the oil draining from the tank when the pump cycles off, it's adjustable (3 to 8 psi) so I can set the "cracking" pressure it needs to open, probably quite low at about 5psi

12. a ball valve, so that the system can be turned off when not in use / overnight, this is a "just in case" as the check valve (11) will not have sufficient residual pressure on it's dischage side to full seat the internal ball.

13. the three way distribution block and fittings that will feed the oil into the transmission casing directly above 3, 4 and 5 gearsets. includes a fitting to put an mechanical temp gauge thermocouple which wil read the temp of the cooled oil returning to the transmission.

all up this is maybe $600 of lemons spend. The chinese oil coolers were $100aud for the pair. The 2 litre resevoir was $60aud. The two check valves ($40 for the discharge valve) and the big bunch of fittings adds up to about $250

It also adds easily 2.5 litres of extra oil capacity to the system, the 2 litre reservoir, plus the capacity of the coolers and the lines means the trans will have close to 6 litres of oil circulating, so pretty much halves it's duty cycle as well as keeping it at a safe temperature.

the dual oil coolers may seem like overkill to some, but it's to allow for varied ambient temps, one race could be at 15/20C and another easily could be 35/40C ambient on the day, ths way the oil won't get too cold on a cold day

SteveC