Dr.Jeff

True Classic

I had a thought for a duct design that could allow for a much larger opening area (increased air flow) while still blending with the X's body lines....let me know what you think.

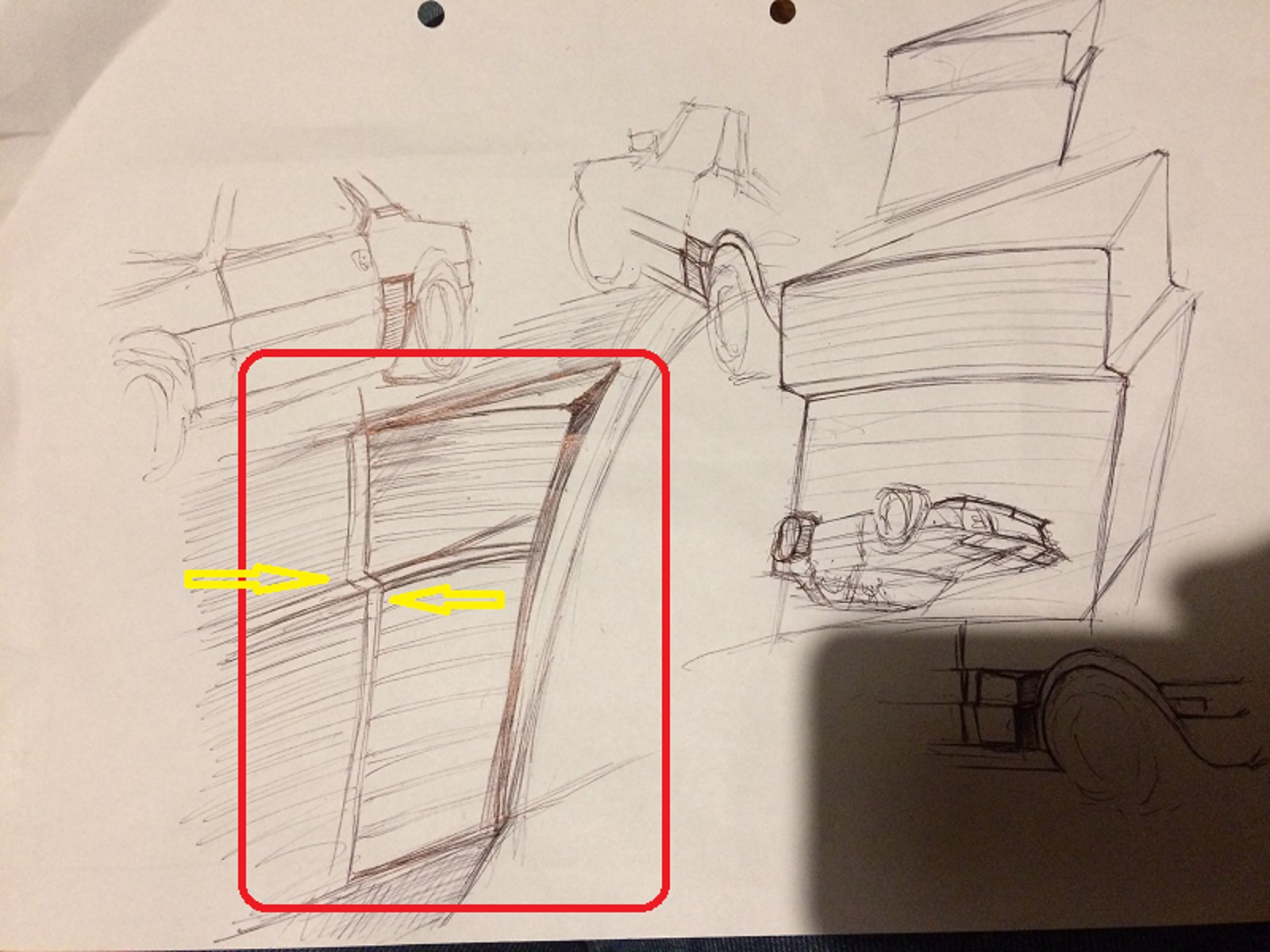

One aspect we have discussed is trying to keep the stock body lines in tact, by integrating the duct into the 'recessed' portion on the sides of the X as it is in stock trim. However this greatly limits the overall size of the duct; going taller (top to bottom) crosses over those body recess lines, and going wider (extended further out to the sides) makes them stick out too far and therefore not proportional. But looking at the drawings offered by Janis earlier, I wonder if proper proportions and a continuation of the body lines could be done on a larger duct/scoop. The thought is to make the duct larger by some ratio (designers need to input here), say 1/3 of it above the upper body line, 1/3 of it below the lower body line, and naturally the last 1/3 the same size as the recess. Then add the same recessed lines (from the body) onto the duct itself. See how Janis did this on the lower portion of the circled image:

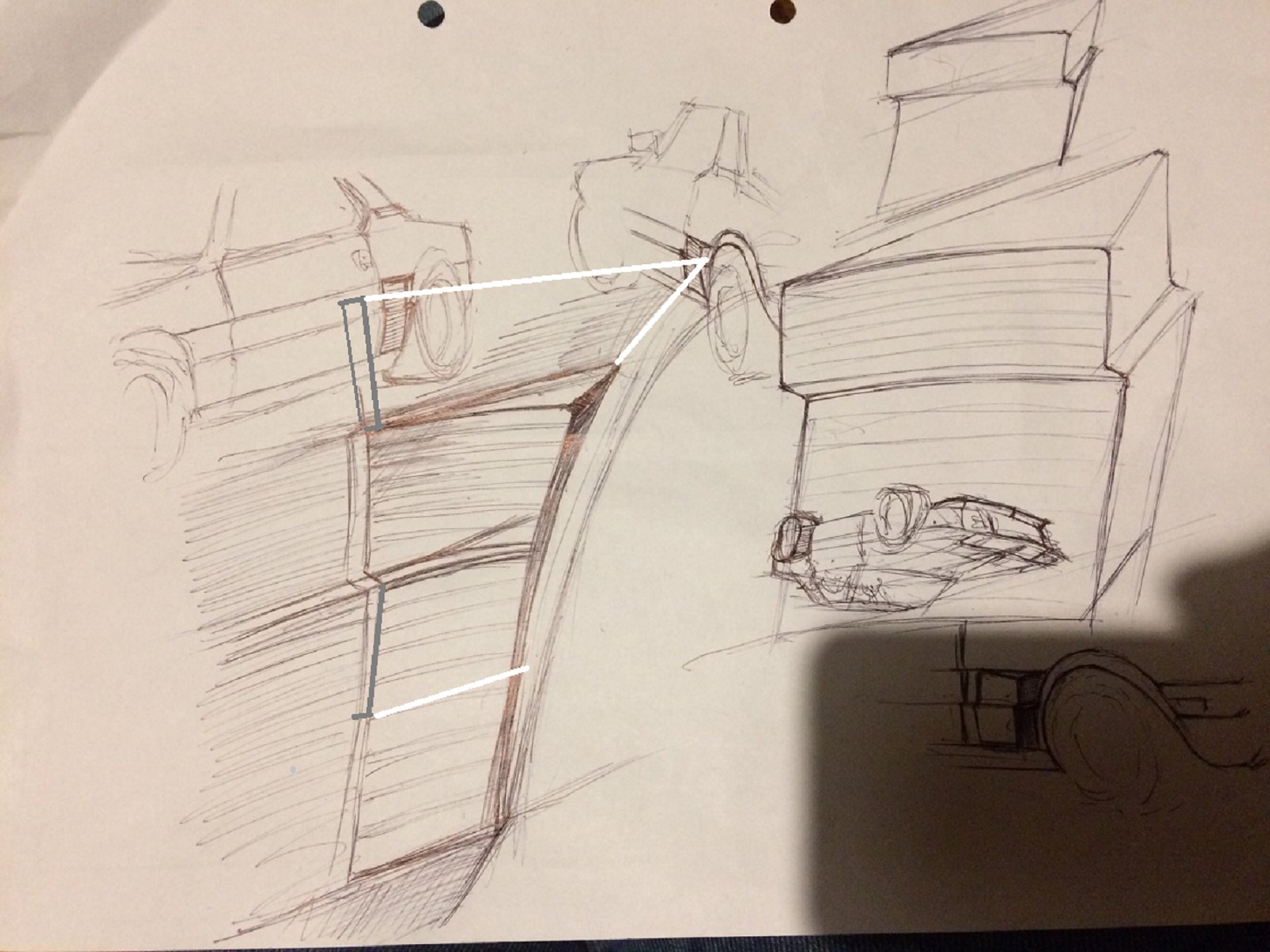

But my thought is to do something like this to both the top and bottom portions, with the overall size being proportioned as just described. So the duct is twice (3 times?) the height but has both body lines (upper and lower aspects of the recess) in it. This added height allows for greater surface area (intake size) without having to go wider (further out) to the sides. And the continuation of the body lines help integrate the added size of it into the X's general design. Naturally the underlying bodywork will need to be modified to allow for a greater opening into the engine bay. Unfortunately I cannot draw or Photoshop this, hopefully someone gets the idea and helps with some sort of image to visualize it. But I'll make a feeble attempt to use "Paint" and add some grey and white lines on Janis' illustration to help convey the idea (although it needs to have more 'rounded' contours than I can do with "Paint"):

Apologizes to Janis for the 'graffiti' on his illustrations.

One aspect we have discussed is trying to keep the stock body lines in tact, by integrating the duct into the 'recessed' portion on the sides of the X as it is in stock trim. However this greatly limits the overall size of the duct; going taller (top to bottom) crosses over those body recess lines, and going wider (extended further out to the sides) makes them stick out too far and therefore not proportional. But looking at the drawings offered by Janis earlier, I wonder if proper proportions and a continuation of the body lines could be done on a larger duct/scoop. The thought is to make the duct larger by some ratio (designers need to input here), say 1/3 of it above the upper body line, 1/3 of it below the lower body line, and naturally the last 1/3 the same size as the recess. Then add the same recessed lines (from the body) onto the duct itself. See how Janis did this on the lower portion of the circled image:

But my thought is to do something like this to both the top and bottom portions, with the overall size being proportioned as just described. So the duct is twice (3 times?) the height but has both body lines (upper and lower aspects of the recess) in it. This added height allows for greater surface area (intake size) without having to go wider (further out) to the sides. And the continuation of the body lines help integrate the added size of it into the X's general design. Naturally the underlying bodywork will need to be modified to allow for a greater opening into the engine bay. Unfortunately I cannot draw or Photoshop this, hopefully someone gets the idea and helps with some sort of image to visualize it. But I'll make a feeble attempt to use "Paint" and add some grey and white lines on Janis' illustration to help convey the idea (although it needs to have more 'rounded' contours than I can do with "Paint"):

Apologizes to Janis for the 'graffiti' on his illustrations.