lezesig1

expatriot

Condition: Side window self drooping, with very little

downward pressure to lower the glass without using the

window crank handle.

Not sealing well.

All door innards were inspected for excessive wear and none found.

Felts, wipers, tracks, cables, gears, shafts, appropriate lube points

all checked good.

No doubt this dilema is solvable by fitment and adjustment of all the many

internal door parts. It's a question of setting the entire assembly into balance

to not have a window pane self droop.

OR

Add a FIAT approved external enhancement device (smile).

Here is my solution. No doubt there are others to address

this issue.

24 Procured a wire-rod, then shaped a hook

and finger pull.

Note: .160 rod diameter used. Steel, cold formed.

85 Procuded a machine screw, nut, and washer.

Note: Chose a 10-24 with a flanged head

(not shown), standard hexnut, and flat washer

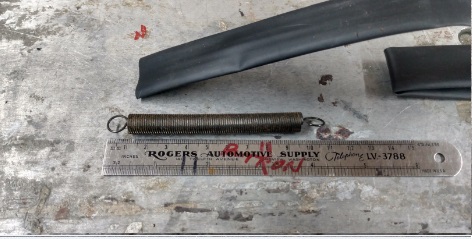

20 Procuded a tension spring.

Procured a section of heatshrink

Note: Chose a closed end spring of 19 (.040) wire gauge

and 120mm in length. Applied heatshrink to the spring to

make an open ended tube. Not too tight.

44 Applied finish to the components. Stud assembly

and finger pull/hook.

Note: Fingernail polish. Enamel, fast cure,

and fairly durable.

79 Drilled and mounted 10-24 threaded insert.

i.e. nutsert, keensert, etc.

Note: Replacing sheet metal screw hole with threaded

hole to allow for more secure stud arrangement.

Fowardmost hole, second from bottom.

Close-up pic of hook securing window hand crank

handle.

Pic showing secured window hand crank handle

under slight tension.

Note: 10-24 anchor stud with minumum exposure. Just enough

to allow for the spring clearance to the door vinyl.

Note: Clocking of window handle with pane raised to full

up position.

Observations.....Worked much better than anticipated. Took very little tension

to lock the glass into the full up position. Blends in well with the stock interior.

Service life on this fitment should be very long. Quick ease of use.

downward pressure to lower the glass without using the

window crank handle.

Not sealing well.

All door innards were inspected for excessive wear and none found.

Felts, wipers, tracks, cables, gears, shafts, appropriate lube points

all checked good.

No doubt this dilema is solvable by fitment and adjustment of all the many

internal door parts. It's a question of setting the entire assembly into balance

to not have a window pane self droop.

OR

Add a FIAT approved external enhancement device (smile).

Here is my solution. No doubt there are others to address

this issue.

24 Procured a wire-rod, then shaped a hook

and finger pull.

Note: .160 rod diameter used. Steel, cold formed.

85 Procuded a machine screw, nut, and washer.

Note: Chose a 10-24 with a flanged head

(not shown), standard hexnut, and flat washer

20 Procuded a tension spring.

Procured a section of heatshrink

Note: Chose a closed end spring of 19 (.040) wire gauge

and 120mm in length. Applied heatshrink to the spring to

make an open ended tube. Not too tight.

44 Applied finish to the components. Stud assembly

and finger pull/hook.

Note: Fingernail polish. Enamel, fast cure,

and fairly durable.

79 Drilled and mounted 10-24 threaded insert.

i.e. nutsert, keensert, etc.

Note: Replacing sheet metal screw hole with threaded

hole to allow for more secure stud arrangement.

Fowardmost hole, second from bottom.

Close-up pic of hook securing window hand crank

handle.

Pic showing secured window hand crank handle

under slight tension.

Note: 10-24 anchor stud with minumum exposure. Just enough

to allow for the spring clearance to the door vinyl.

Note: Clocking of window handle with pane raised to full

up position.

Observations.....Worked much better than anticipated. Took very little tension

to lock the glass into the full up position. Blends in well with the stock interior.

Service life on this fitment should be very long. Quick ease of use.