Ok... report time. Hesitantly, and with fingers crossed, I think we might have gotten it right.

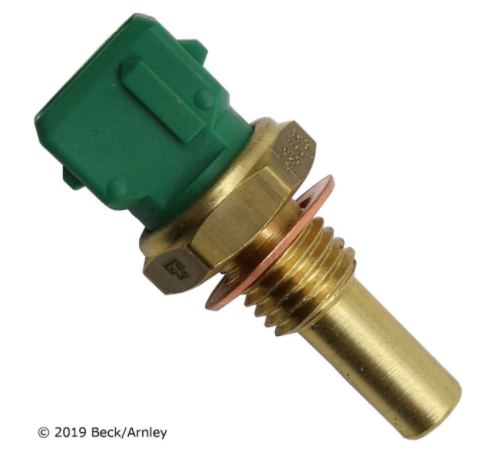

The part arrived from Midwest Bayless about an hour ago. I had a few minutes, so I headed out to the garage. In trying to remove the connector, I ended up pulling the wires out-- oops. Took a bit of fiddling around trying to find an angle to get the wrench onto the old sensor. Got it out, got the new one in, and only lost an ounce or two of antifreeze in the process! Had to work a bit to get the pins back into the connector, and got the connector reinstalled.

Go to start the car, and it doesn't want to start... it just really, really didn't want to start. Just cranked and cranked with no popping or attempting to catch. Gave it a shot of ether (which I hate doing) and it finally started. Idled fine, at about 800rpm, when cold. As it started to warm up, the idle dropped to around 500rpm, and it wanted to stall... but didn't. I goosed it a bit, and it came back to life. Used a piece of duct tape to hold the idle around 1000rpm, and it proceeded to run fine for the next 30 minutes. As soon as I removed the tape, the idle dropped back down again, and it wanted to stall (but didn't!). I also stopped and restarted it a couple of times, and it started back up fine when warm, which it hasn't been doing.

When it finally stops raining (it's rained every day here since the middle of June), I'm going to make an appointment to get it inspected, and say a little prayer than it makes it there without leaving me stranded!

So I'm left with 2 questions...

- I've read the section of the FSM that talks about how to adjust the idle, and I don't really understand what it wants me to do. I'd welcome any explanation. I'd like to bring it up to run about 1000rpm when warm-- it seemed happy there.

- As noted in one of the early posts in this thread, the temp gauge doesn't move as the car warms up. I do have a spare dash, and can swap that in to see if the gauge itself has gone bad, but I'm open to any other troubleshooting ideas you guys might have.

As always, thanks for your patience, responsiveness, and willingness to help.