Dr.Jeff

True Classic

I have a set of 4 Koni struts for the X1/9. They are new (as in never been used), but old (as in manufactured back in the 80's). Due to their extended shelf existence I decided the best thing would be to service them before installation. In this case I refer to a "service" as a complete tear down, inspection, cleaning, seal replacement, fluid replacement, and reassembly. This is opposed to a "rebuilding", which would include those items plus replacement of the bushing, any worn/damaged parts, and possibly revalving. I did not take photos until most of the work had been done but here is a brief summary (not intended to be a detailed "how to"). The photos I have (at the end) will help to follow the description, but a little back and forth may be needed to see things as we go along.

These Koni's were specifically made for the X1/9 application, to replace the stock struts. So they had standard spring perches and install using the stock mounts. Their dampening is 'adjustable', but only for rebound (compression is not adjustable). I'm not sure how their valving compares to the original stock Fiat struts, but imagine they were considered an upgrade and therefore firmer. Depending on the springs utilized, the dampening could be externally adjusted to suit. For my use I am converting them to coil-over units. Therefore I cut off the stock spring perches and added retaining rings to allow the addition of threaded collars. The springs that will be used are stiffer than the stock springs but not by a lot. I want a decent quality ride for normal street driving, but a little firmer for handling and to prevent bottoming out - they will have an adjustable ride height enable lowering the car (purely for aesthetics).

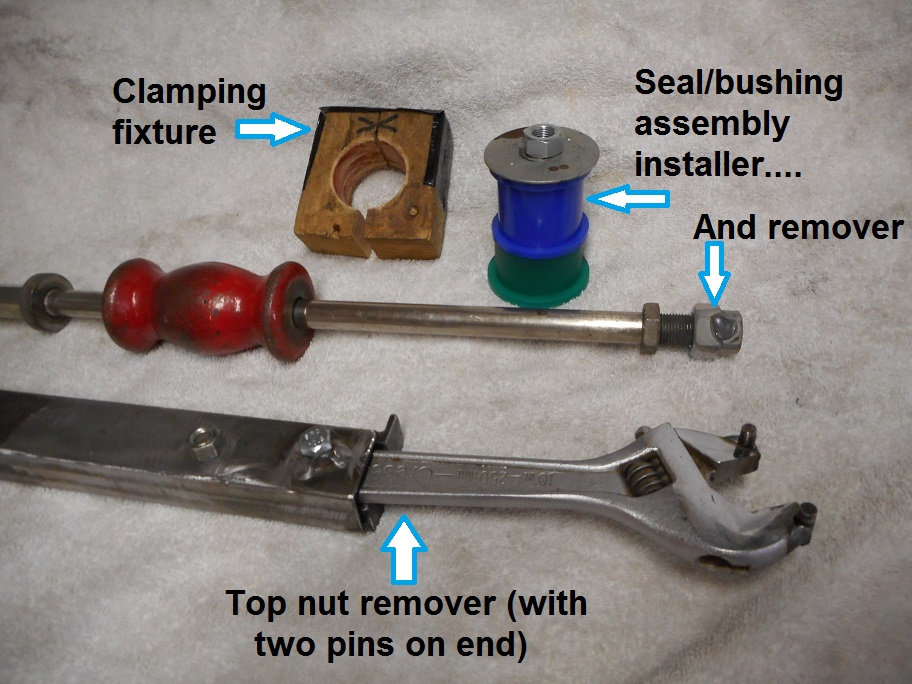

Disassembly begins by removing the top nut (collar or cap). These nuts have a pair of holes in the top of them and round circumference. Therefore you can't use a regular style wrench, but must use a special removal tool. These tools are available but not worth the cost for my needs, so I made one. I also made a simple wood fixture to hold the housing in a large vice while working on it.

After that nut is removed, the seal / rod-bushing assembly is pulled out. This does not come out easily; there is a O-ring to seal it into the outer tube (housing), and some sort of force is needed to slide it upward. I fashioned another tool to do that, utilizing a slide hammer and adapter piece. For reassembly, the seal/rod-bushing assembly must be pressed back into the housing. I used a couple of left over urethane bushings to do that.

Next the main shaft (rod) can be drawn out, along with the inner tube assembly. The bottom end of the inner tube holds a valve disc assembly. Connected to the end of the main rod there is another valve assembly. One valve controls compression movement, the other rebound movement. There is a stack of thin discs in these valves. By replacing the discs you can revalve (tune) the dampening action as desired for compression and for rebound. For my needs I wanted a slightly firmer overall dampening effect but did not want to completely revalve it. So I replaced the fluid with a heavier weight suspension fluid instead.

Although these units had never been used the insides were rather dirty. The original fluid in them was petroleum based and degrades over time, even without use. Plus a minute amount of moisture in the air trapped inside them contributes to further decay. To thoroughly clean them, everything needs to be completely disassembled (including the valve assemblies, etc). Keep track of all the little bits and be sure to replace them the same way they came out. I used synthetic suspension fluid of approximately 40% heavier viscosity. But that does not equate to a 40% stiffer action (it has less of an effect than the numbers might suggest). New Viton seals and reassembly in the opposite order.

Here are some pics. They were taken during assembly, but I will show them in reverse order to represent disassembly:

1) The complete strut assembly, with modified outer housing and coil-over threaded sleeve.

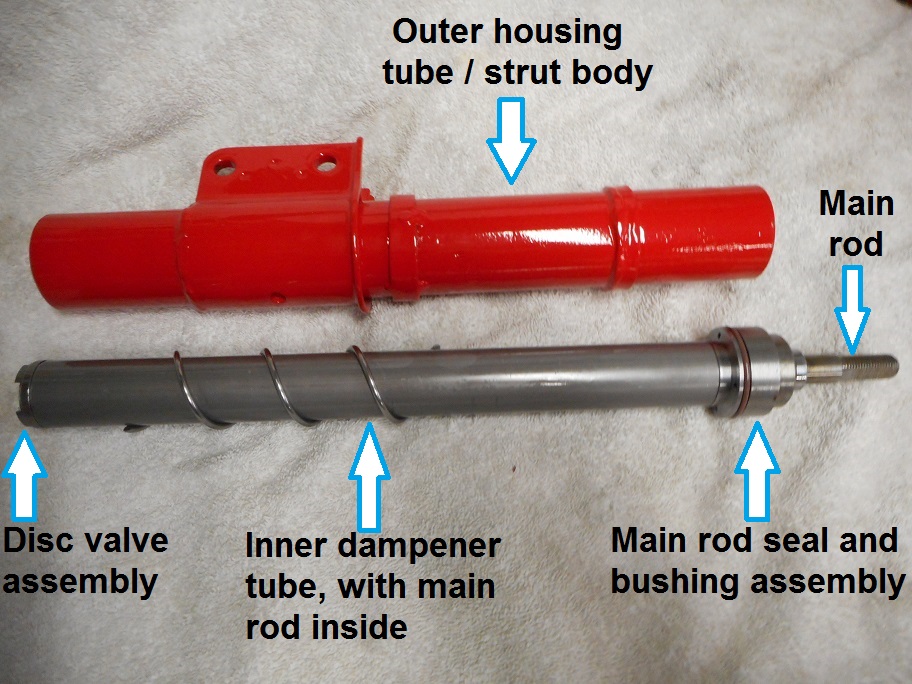

2) The outer tube/housing and the inner tube dampener assembly.

3) Top nut/cap. Notice pair of small holes through it (not well shown here). The removal tool has a pair of pins that attach into these holes.

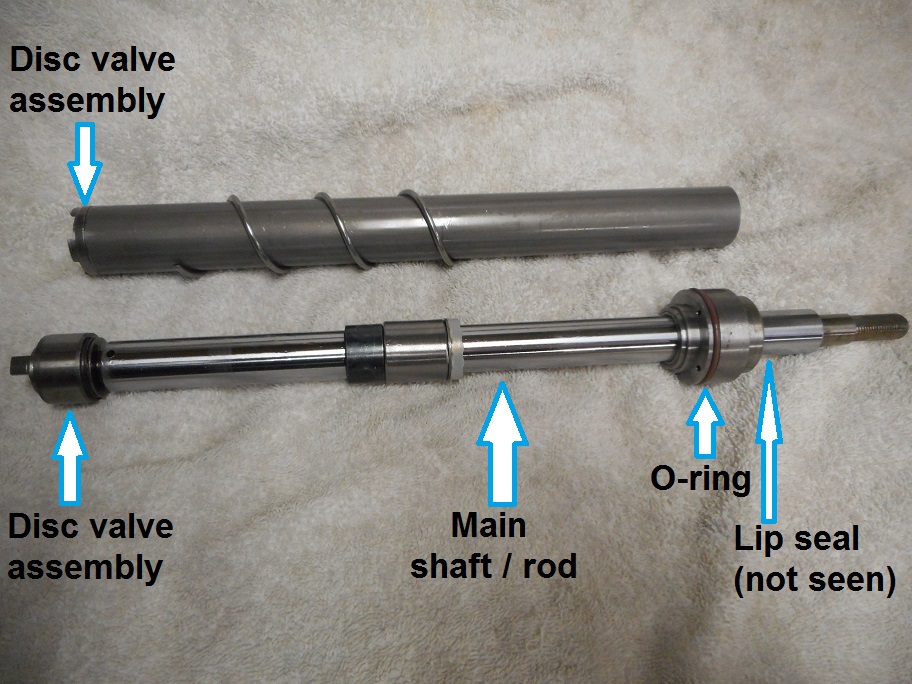

4) Main rod/shaft and inner dampener tube. The rod slides through the seal/bushing assembly. There are two disc valves; one is on the inner tube, and the other on the rod.

5) Close up of the two valve assemblies. These are what can "tune" the shock ('revalving') by changing the discs inside them.

6) Close up of the main rod seal and bushing assembly. There are two seals; a O-ring to seal the assembly to the outer housing, and a lip seal to seal the main rod as it travels up and down. The lip seal is what wears and allows fluid to leak outside of the strut. A sleeve bushing inside this assembly is what the rod rides on. When it wears the rod gets side-to-side play, allowing other things to wear out quickly.

7) Some simple tools I made to work on the Koni's.

Later I might take a photo of the completed coil-over strut assembly ready to be installed. I can also give a few more servicing details and photos if requested.

These Koni's were specifically made for the X1/9 application, to replace the stock struts. So they had standard spring perches and install using the stock mounts. Their dampening is 'adjustable', but only for rebound (compression is not adjustable). I'm not sure how their valving compares to the original stock Fiat struts, but imagine they were considered an upgrade and therefore firmer. Depending on the springs utilized, the dampening could be externally adjusted to suit. For my use I am converting them to coil-over units. Therefore I cut off the stock spring perches and added retaining rings to allow the addition of threaded collars. The springs that will be used are stiffer than the stock springs but not by a lot. I want a decent quality ride for normal street driving, but a little firmer for handling and to prevent bottoming out - they will have an adjustable ride height enable lowering the car (purely for aesthetics).

Disassembly begins by removing the top nut (collar or cap). These nuts have a pair of holes in the top of them and round circumference. Therefore you can't use a regular style wrench, but must use a special removal tool. These tools are available but not worth the cost for my needs, so I made one. I also made a simple wood fixture to hold the housing in a large vice while working on it.

After that nut is removed, the seal / rod-bushing assembly is pulled out. This does not come out easily; there is a O-ring to seal it into the outer tube (housing), and some sort of force is needed to slide it upward. I fashioned another tool to do that, utilizing a slide hammer and adapter piece. For reassembly, the seal/rod-bushing assembly must be pressed back into the housing. I used a couple of left over urethane bushings to do that.

Next the main shaft (rod) can be drawn out, along with the inner tube assembly. The bottom end of the inner tube holds a valve disc assembly. Connected to the end of the main rod there is another valve assembly. One valve controls compression movement, the other rebound movement. There is a stack of thin discs in these valves. By replacing the discs you can revalve (tune) the dampening action as desired for compression and for rebound. For my needs I wanted a slightly firmer overall dampening effect but did not want to completely revalve it. So I replaced the fluid with a heavier weight suspension fluid instead.

Although these units had never been used the insides were rather dirty. The original fluid in them was petroleum based and degrades over time, even without use. Plus a minute amount of moisture in the air trapped inside them contributes to further decay. To thoroughly clean them, everything needs to be completely disassembled (including the valve assemblies, etc). Keep track of all the little bits and be sure to replace them the same way they came out. I used synthetic suspension fluid of approximately 40% heavier viscosity. But that does not equate to a 40% stiffer action (it has less of an effect than the numbers might suggest). New Viton seals and reassembly in the opposite order.

Here are some pics. They were taken during assembly, but I will show them in reverse order to represent disassembly:

1) The complete strut assembly, with modified outer housing and coil-over threaded sleeve.

2) The outer tube/housing and the inner tube dampener assembly.

3) Top nut/cap. Notice pair of small holes through it (not well shown here). The removal tool has a pair of pins that attach into these holes.

4) Main rod/shaft and inner dampener tube. The rod slides through the seal/bushing assembly. There are two disc valves; one is on the inner tube, and the other on the rod.

5) Close up of the two valve assemblies. These are what can "tune" the shock ('revalving') by changing the discs inside them.

6) Close up of the main rod seal and bushing assembly. There are two seals; a O-ring to seal the assembly to the outer housing, and a lip seal to seal the main rod as it travels up and down. The lip seal is what wears and allows fluid to leak outside of the strut. A sleeve bushing inside this assembly is what the rod rides on. When it wears the rod gets side-to-side play, allowing other things to wear out quickly.

7) Some simple tools I made to work on the Koni's.

Later I might take a photo of the completed coil-over strut assembly ready to be installed. I can also give a few more servicing details and photos if requested.