You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 2400 mile ADVENTURE to buy my next 1974 X1/9 (WARNING - LONG READ & LOTS OF IMAGES):

- Thread starter zonker

- Start date

zonker

Just Another FIAT Freak

Suspense is over, thankfully. Car is home and even got it's first exterior wash in probably 2 years.Great adventure, like thriller with suspense.

dllubin

Don

Fiat must have had something unusual going on in 1974 when they assigned X1/9 serial numbers. I have a 6/74 build date but my SN is over a thousand higher than yours. This issue came up when I ordered a clutch/pressure plate from MWB. Matt sent me the tall PP based on the fact that he had never seen a true 74 with a short PP. It was determined later that the whole transaxle/pressure plate revision was tied to engine number 2050998 and above. My 74 had a higher engine number than that. The change was targeted at 75 production but somehow my car ended up with it. The only thing that I can think of is maybe they pulled off a bunch of cars for California builds and they ended up with SNs out of chronological build sequence.

zonker

Just Another FIAT Freak

Being you're the original owner, I cannot lay the PO stuff on you. I can attest that this '74 is a bit different than my last '74, which had a 6/74 build date. But if that happened on the assembly line or the previous ownership(s), I do not know.Fiat must have had something unusual going on in 1974 when they assigned X1/9 serial numbers. I have a 6/74 build date but my SN is over a thousand higher than yours. This issue came up when I ordered a clutch/pressure plate from MWB. Matt sent me the tall PP based on the fact that he had never seen a true 74 with a short PP. It was determined later that the whole transaxle/pressure plate revision was tied to engine number 2050998 and above. My 74 had a higher engine number than that. The change was targeted at 75 production but somehow my car ended up with it. The only thing that I can think of is maybe they pulled off a bunch of cars for California builds and they ended up with SNs out of chronological build sequence.

As for the clutch, yes the '74's did have the taller 45mm pressure plate, but were frequently replaced with the short 38mm one, and the shorter one will work on the original '74 model trans, but the taller one will not (clearance issue inside the bellhousing). This '74 has had a trans replacement prior to me so I do not think it's original. It had a later trans and a 38mm clutch cover. The way you can tell externally if your trans is the 75-78 model is if it has two electric switches (reverse light and 3-4 gear engagement). The 74 trans only has the one reverse light switch.

dllubin

Don

Actually, the 74 also has two switches. The second switch lets the seat belt interlock system know that the car is in gear. It is down at the bottom. I have a vague recollection of a Molex style plug with wiring along the lower cross member. What did the 3-4 gear engagement switch control?Being you're the original owner, I cannot lay the PO stuff on you. I can attest that this '74 is a bit different than my last '74, which had a 6/74 build date. But if that happened on the assembly line or the previous ownership(s), I do not know.

As for the clutch, yes the '74's did have the taller 45mm pressure plate, but were frequently replaced with the short 38mm one, and the shorter one will work on the original '74 model trans, but the taller one will not (clearance issue inside the bellhousing). This '74 has had a trans replacement prior to me so I do not think it's original. It had a later trans and a 38mm clutch cover. The way you can tell externally if your trans is the 75-78 model is if it has two electric switches (reverse light and 3-4 gear engagement). The 74 trans only has the one reverse light switch.

If the short PP can be used on the early 4 speed, I wonder why they bother to make both styles? Seems like the extra inventory would cost money.

zonker

Just Another FIAT Freak

Actually, the 74 also has two switches. The second switch lets the seat belt interlock system know that the car is in gear. It is down at the bottom. I have a vague recollection of a Molex style plug with wiring along the lower cross member. What did the 3-4 gear engagement switch control?

If the short PP can be used on the early 4 speed, I wonder why they bother to make both styles? Seems like the extra inventory would cost money.

Ah the 74's interlock system. That makes more sense. 3-4 gear switch was used I think on the dual point 124's to identify when to trigger the second set of points thereby altering the ignition timing.

Evolution of the breed. My understanding is the casting change for the 4 speed was needed in order to assist with new internals, which paved the way for a future 5 speed? At least that's what I heard around the water cooler. The synchros and sliders were changed at that time as well.

dllubin

Don

The most visible change was the steel shaft plug inside the bellhousing being replaced with aluminum as part of the bellhousing.Ah the 74's interlock system. That makes more sense. 3-4 gear switch was used I think on the dual point 124's to identify when to trigger the second set of points thereby altering the ignition timing.

Evolution of the breed. My understanding is the casting change for the 4 speed was needed in order to assist with new internals, which paved the way for a future 5 speed? At least that's what I heard around the water cooler. The synchros and sliders were changed at that time as well.

kmead

Old enough to know better

That DAF with the Vermont plate stands out. I presume there is a story around that one as well?At least that's what I heard around the water cooler.

zonker

Just Another FIAT Freak

Oh yeah. Grew up in Holland where those little cars were made a few miles from where I lived. They were everywhere. That one came from the DAF museum in Vermont, and was professionally transported to CA. I keep it registered in VT because you can't register it in CA. It's a 2 cyl air cooled 843cc boxer engine mounted up front with the first ever automotive application CVT trans mounted near the differential. The Van Doornes owned DAF as well as the patent rights to the CVT. To this day they get royalties for all other applications of this technology from scooters to snowmobiles to cars and trucks.That DAF with the Vermont plate stands out. I presume there is a story around that one as well?

Last edited:

Bjorn Nilson

True Classic

I had, or rather my ex-wife had a Volvo 66 "variomatic"which is basically a DAF in the early 90's. We called them "Belt Johan" here in Sweden. What I remember it constantly revved 4000 rpm at any speed, and I could probably reverse it in 130 km/h.

One of the cars I don't regret I've sold.

One of the cars I don't regret I've sold.

zonker

Just Another FIAT Freak

The 66 used a 4 cyl Renault water cooled motor. When the vacuum system on the variomatic fails to work, you get that 4000rpm feeling because the CVT only works on the centrifugal system so it doesn't ramp up the pulleys to lower the rpm at light loads so it feels like you're driving forever in a low gear.I had, or rather my ex-wife had a Volvo 66 "variomatic"which is basically a DAF in the early 90's. We called them "Belt Johan" here in Sweden. What I remember it constantly revved 4000 rpm at any speed, and I could probably reverse it in 130 km/h.

One of the cars I don't regret I've sold.

zonker

Just Another FIAT Freak

Oh the fun hours you have ahead@zonker Rob; about 9 months ago I purchased my ‘75 X/19 . Today is my first day on forum. Your purchase story inspired me to get my “ been stored in a garage for 15 years “ let’s get this party started story. Only my purchase was hiding in a garage 2 blocks from my house, so no road trip. Previous owner brought it to me on trailer, after wheeling & dealing with him for about 6 months to finally pry it away from him for yes, 1500. ( he inherited it from dear departed dad) I seen it outside his garage one day on a trailer, and so I pulled over & asked if it was for sale. 6 months later it was mine. He told me it was running when it was parked. Bought as is . I haven’t touched it yet other than sticking a tube in gas tank to check for any sign of gas and there’s a little in there smells like varnish. Anyway, after reading your story, I became scared and excited to start reaching out for help to start my resurrection process. Financially, I can only do 1 task right now and I’m thinking get gas tank cleaned out. I need advice on that please; ( what tools on down ) Thanks!

When I did this step on the yellow '74, fuel almost instantly came out clear, but I immediately had a leak around the fuel pump diaphragm. I disconnected the fuel hoses to the fuel pump and replaced all fuel lines and fuel filter as well as picking up a low pressure electric fuel pump at the local Autozone. The electric pump bolt pattern matched that of the carburetor fan mount so it was nearly a plug and play situation. The new pump has a fuel inlet filter to trap stuff before it enters the pump, main filter, or carb, so that's a plus. For wiring, it was simple, the ground terminal had an eyelet that fit on the mounting stud, and the 12v + wire was wired to the positive terminal on the ignition coil. The engineer types will tell you to wire in a relay and a rollover switch, and down the road I probably will do that to the little booger, but at this stage of the game, you just need to find out if the car will keep all it's fluids and run like it should so don't bother.

Last edited:

Bjorn Nilson

True Classic

I thought that was the whole idea with the belt system. -Maximum torque, always. I don't remember if our 66 behaved differently from other DAF or Volvo 66, but I don't think so.The 66 used a 4 cyl Renault water cooled motor. When the vacuum system on the variomatic fails to work, you get that 4000rpm feeling because the CVT only works on the centrifugal system so it doesn't ramp up the pulleys to lower the rpm at light loads so it feels like you're driving forever in a low gear.

zonker

Just Another FIAT Freak

If you keep your foot in it' negating any manifold vacuum then yes, it will ramp up to peak power band and keep the motor there. If you let off the gas, the increased manifold vacuum would actuate the vacuum side of the variator disc and move the pulley halves together for a low rpm economic cruise. The one I bought was like this - it would rap out that 2 cyl and stay there all the way to 80mph. If I was lucky it would drop to 3000 rpm at lower speeds. With it working correctly, it will motor on to 45mph at 2000-2500rpm, a much more enjoyable experience.I thought that was the whole idea with the belt system. -Maximum torque, always. I don't remember if our 66 behaved differently from other DAF or Volvo 66, but I don't think so.

BellaDavina’75 X/19

Low Mileage

Thank you for the reply. I will study your instructions and go from there. I’m a total rookie, so pleaseOh the fun hours you have ahead. Seriously though, just because it smells like varnish doesn't mean you need to pull the tank. The way I would attack this is to attach a vacuum bleeder to the hose where it reaches the carb. Start pulling the fuel into the bleeder reservoir until you completely drain the tank. Once you suction out the old fuel, add some new gas, then get a clear fuel filter so you can observe what kind of debris is being pulled thru the hose, and with the new fuel suction out a couple cups of fuel. If the filter stays relatively clear and no leaks are occurring on the hoses or near the fuel pump, it's good enough to attach to the carb to get the next step of the project started.

When I did this step on the yellow '74, fuel almost instantly came out clear, but I immediately had a leak around the fuel pump diaphragm. I disconnected the fuel hoses to the fuel pump and replaced all fuel lines and fuel filter as well as picking up a low pressure electric fuel pump at the local Autozone. The electric pump bolt pattern matched that of the carburetor fan mount so it was nearly a plug and play situation. The new pump has a fuel inlet filter to trap stuff before it enters the pump, main filter, or carb, so that's a plus. For wiring, it was simple, the ground terminal had an eyelet that fit on the mounting stud, and the 12v + wire was wired to the positive terminal on the ignition coil. The engineer types will tell you to wire in a relay and a rollover switch, and down the road I probably will do that to the little booger, but at this stage of the game, you just need to find out if the car will keep all it's fluids and run like it should so don't bother.

Oh the fun hours you have ahead. Seriously though, just because it smells like varnish doesn't mean you need to pull the tank. The way I would attack this is to attach a vacuum bleeder to the hose where it reaches the carb. Start pulling the fuel into the bleeder reservoir until you completely drain the tank. Once you suction out the old fuel, add some new gas, then get a clear fuel filter so you can observe what kind of debris is being pulled thru the hose, and with the new fuel suction out a couple cups of fuel. If the filter stays relatively clear and no leaks are occurring on the hoses or near the fuel pump, it's good enough to attach to the carb to get the next step of the project started.

When I did this step on the yellow '74, fuel almost instantly came out clear, but I immediately had a leak around the fuel pump diaphragm. I disconnected the fuel hoses to the fuel pump and replaced all fuel lines and fuel filter as well as picking up a low pressure electric fuel pump at the local Autozone. The electric pump bolt pattern matched that of the carburetor fan mount so it was nearly a plug and play situation. The new pump has a fuel inlet filter to trap stuff before it enters the pump, main filter, or carb, so that's a plus. For wiring, it was simple, the ground terminal had an eyelet that fit on the mounting stud, and the 12v + wire was wired to the positive terminal on the ignition coil. The engineer types will tell you to wire in a relay and a rollover switch, and down the road I probably will do that to the little booger, but at this stage of the game, you just need to find out if the car will keep all it's fluids and run like it should so don't bother

zonker

Just Another FIAT Freak

No worries, if you have any questions that might seem tough to ask in a public forum, you can always private message me here.Bear with me

BellaDavina’75 X/19

Low Mileage

Thank you so muchNo worries, if you have any questions that might seem tough to ask in a public forum, you can always private message me here.

kmead

Old enough to know better

Don’t hesitate to post any question on the workshop forum related to your car. We have all been a ‘newbie’ at some point on these cars. We don’t mind answering questions or vectoring you to the right answer. I would strongly suggest buying a few manuals to assist with your repairs. The Haynes manual is a good one with great illustrations, it may not have all the correct answers due to being produced in England for an EU car but it does cover how to get it apart and back together very well. The factory manual is available here on the WIKI and also can be had from another website called MiraFiori.com if you become a member (just signup, no fees).View attachment 59609Hi family, honestly I’m guessing on how to use this website, I don’t own a computer I’m on a cell phone, so even right now I’m guessing that this reply is directed @zonker . I’ve never been in a forum, chat whatever it’s called but I’m ready to learn ; hit or miss .I’ll self teach . & thank y’all so much for your patience. This is my version of “ James Dean’s “ little bastard which is also nick named “lil bastard” can’t wait for the day to paint that on the Back ! WHOA

Again post up a question and you will enjoy the benefit of many members experience in helping you fix up your X.

’’

zonker

Just Another FIAT Freak

A little update on the yellow '74 I affectionately call the lil' booger:

After the drive home, the clutch pedal was dropping to the floor. I found that the clutch slave adjustment ball was not secured in position with a locknut and backed it self off to the point where the rod was barely articulating the pressure plate. A stop nut solved that problem, as well as a new clutch slave return spring.

Since that day, I've put about another 500 miles on him and so far nothing new has broken. This means my time spent on it has been to fix/upgrade what has not been attended to.

First was electrical. The car had been equipped with no less than 3 fuse panels, and exposed and unused wires everywhere. The gauge cluster had the jumping speedo needle issue and the only other item that worked on it was an intermittent tach needle and the low fuel light. I sourced a UK 1300 X1/9 "gunsight" style instrument panel and replaced the 3 fuse boxes with one from a 124 Spider (same 12 fuses but all are standard size). It did require I move fuse 11 to the dome light fuse since the source current for the 124 fuse box has a common source current for 11/12 and the X1/9 does not.

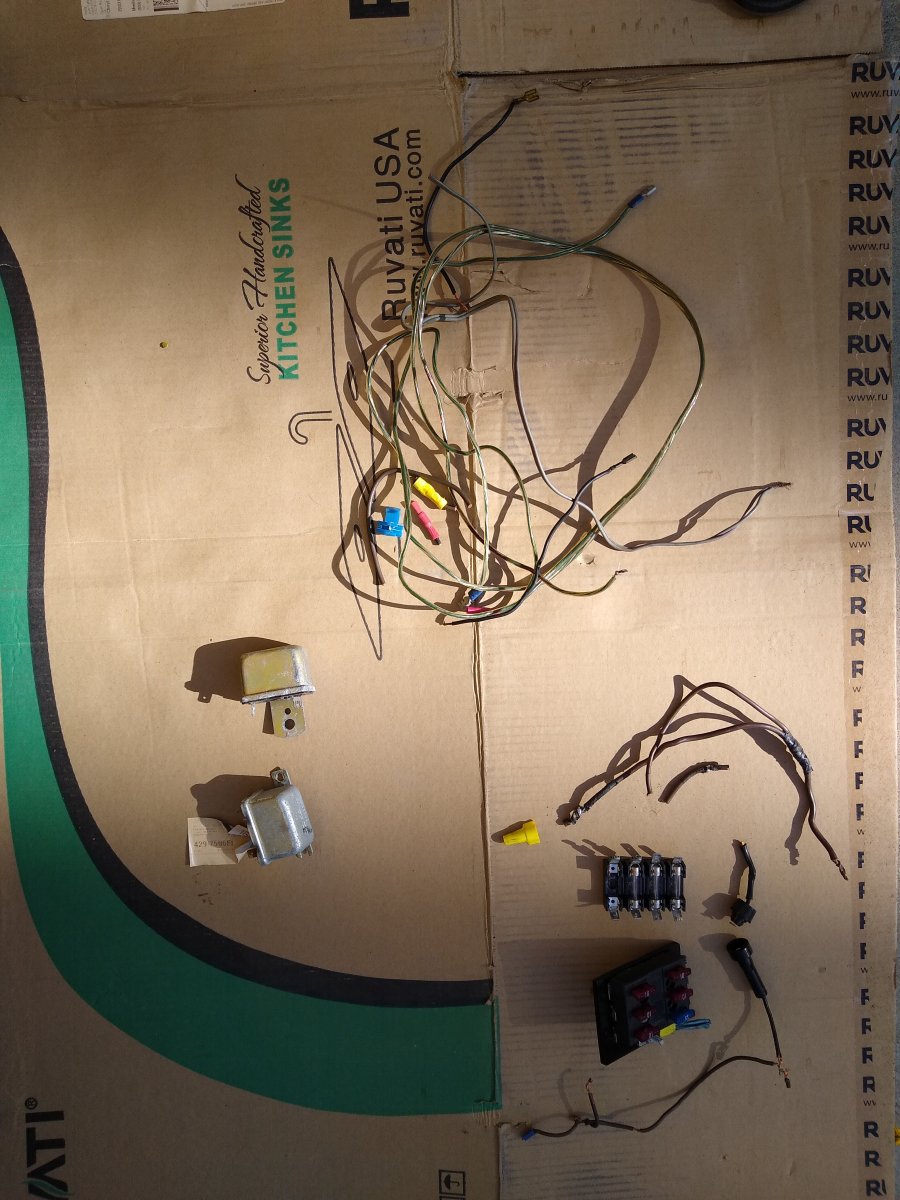

Some pics of what was pulled out from under the dash:

Next order of business was changing out the rearview mirror, doing a home made 4 wheel string alignment, and adding a set of 15x6 wheels with 175/55-15 fronts and 195/50-15 rears. Wheels and tires are 2-4 lbs lighter than the OEM steel wheels and 175/70-13 tires I pulled from him.

This last weekend, I tagged along with a Fiat 124 Spider group and took the booger canyon carving in So. Cal. We covered Carbon Canyon Rd, Santiago Cyn. Rd, and Ortega Hwy. The drive was flawless.

After the drive home, the clutch pedal was dropping to the floor. I found that the clutch slave adjustment ball was not secured in position with a locknut and backed it self off to the point where the rod was barely articulating the pressure plate. A stop nut solved that problem, as well as a new clutch slave return spring.

Since that day, I've put about another 500 miles on him and so far nothing new has broken. This means my time spent on it has been to fix/upgrade what has not been attended to.

First was electrical. The car had been equipped with no less than 3 fuse panels, and exposed and unused wires everywhere. The gauge cluster had the jumping speedo needle issue and the only other item that worked on it was an intermittent tach needle and the low fuel light. I sourced a UK 1300 X1/9 "gunsight" style instrument panel and replaced the 3 fuse boxes with one from a 124 Spider (same 12 fuses but all are standard size). It did require I move fuse 11 to the dome light fuse since the source current for the 124 fuse box has a common source current for 11/12 and the X1/9 does not.

Some pics of what was pulled out from under the dash:

Next order of business was changing out the rearview mirror, doing a home made 4 wheel string alignment, and adding a set of 15x6 wheels with 175/55-15 fronts and 195/50-15 rears. Wheels and tires are 2-4 lbs lighter than the OEM steel wheels and 175/70-13 tires I pulled from him.

This last weekend, I tagged along with a Fiat 124 Spider group and took the booger canyon carving in So. Cal. We covered Carbon Canyon Rd, Santiago Cyn. Rd, and Ortega Hwy. The drive was flawless.

Last edited: