You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turbo systems for X1/9's

- Thread starter Dr.Jeff

- Start date

Dr.Jeff

True Classic

Honestly I don't know if there are the same E85 issues here with the percentage of alcohol. As I said, I haven't looked into it before. But I wonder if the "flex-fuel" sensors can detect the differences and signal the ECU to tune accordingly? That's what those sensors are for on production vehicles, but I don't know how accurate or sensitive they are.It seems like E85 is good for applications with a lot of boost as it helps preventing detonation and improves cooling. E85 is commonly used in Sweden in racing, drifting and drag racing. However the pump E85 is not what it used to be. The quality varies from E72 to E82 so it can not longer be used for serious tuning and racing. I prepared my car for E85 but gave up because of the varying quality.

Btw, I recently met a guy at a car meet who had an old super nice Fiat 500 with an Uno T engine. He has 257whp@2.3 bar boost running Premium 98 octane gasoline (just like I do with 1.6 bar boost) so obviously traditional fuel also works well. Maybe it is time to buy a bigger turbo.

And yes, 2.3 bar is a lot of boost.

Simon Oaten

Daily Driver

the setup doco on the main site is also v good.

the tech docs from continental are v good.

NBB

accuracey - so back checking with known conc is a good procedure

there are also "off the shelf" click-on type fittings to enable AN connectors to be used.

Dr.Jeff

True Classic

For my turbo X1/9 project build ("Turbo X", discussed previously in this thread), the overall idea is to see how adding a relatively low boost turbo to a good condition stock X engine will work. The goal is to keep the total cost as low as possible while making the engine reliable enough to be driven on the street like a stock car. Therefore ultimate performance is not the objective - but increasing the output enough to make the X more fun and "drivable" is....even with air conditioning and other conveniences to keep it comfortable. Much like a factory turbo package on production vehicles. Think of it as a Uno Turbo in X1/9 clothing, but utilizing the X's SOHC engine as the basis rather than doing a complete UT swap. By keeping the engine stock, this formula could then be applied to most any X without breaking the bank. In fact the costs can be considerably less than building a high performance NA X engine, while offering better performance for a road car (i.e. more torque), and more reliability.

Last night I came across a article where this exact same idea was done to a old school American V8. The engine was from a 80's vehicle so it was a low power, emissions regulated one - with a very weak cam, small ports/valves, restrictive manifolds, etc. They started with a 100% bone stock engine and added a value priced ("imported") single turbo to it. The turbo was very sensibly sized and coupled with a intercooler, nothing more....no meth, alcohol, or water spray, no fancy controllers, and no special fuels (just regular pump gas) were used. The stock intake and exhaust manifolds, cam, pistons, rods, heads, ignition (slightly retarded timing), induction (enriched as needed), etc, were all retained. They tested the engine on a dyno; first without the turbo, then with 6-7 PSI boost, and finally with 9-10 PSI. To summarize the dyno graphs, the lower boost level added a 40 to 45% increase in horsepower and torque over no turbo, and the higher boost added a 60 to 70% increase. And the peak "boosted" power increases were actually at lower RPMs than the peak stock numbers (for both torque and HP). The overall torque curve saw the greatest benefit, but both the torque and HP curves were quite flat (similar to the non-turbo setup). There was no indication of detonation or premature wear/damage upon tear down following numerous runs. The stock factory internal components held up well to the low boost levels, most likely due to the use of a decent intercooler and reasonable tune. The total build costs (including freshening up the engine) was under $2000. You cannot build a performance NA engine for that.

This was encouraging to see. That is what I hope to find with my "Turbo X" build; around 50% increases in torque and HP, with broad flat curves, at street friendly RPMs. I think that should make for a decent 'driver' X, what it should have had from the factory.

Last night I came across a article where this exact same idea was done to a old school American V8. The engine was from a 80's vehicle so it was a low power, emissions regulated one - with a very weak cam, small ports/valves, restrictive manifolds, etc. They started with a 100% bone stock engine and added a value priced ("imported") single turbo to it. The turbo was very sensibly sized and coupled with a intercooler, nothing more....no meth, alcohol, or water spray, no fancy controllers, and no special fuels (just regular pump gas) were used. The stock intake and exhaust manifolds, cam, pistons, rods, heads, ignition (slightly retarded timing), induction (enriched as needed), etc, were all retained. They tested the engine on a dyno; first without the turbo, then with 6-7 PSI boost, and finally with 9-10 PSI. To summarize the dyno graphs, the lower boost level added a 40 to 45% increase in horsepower and torque over no turbo, and the higher boost added a 60 to 70% increase. And the peak "boosted" power increases were actually at lower RPMs than the peak stock numbers (for both torque and HP). The overall torque curve saw the greatest benefit, but both the torque and HP curves were quite flat (similar to the non-turbo setup). There was no indication of detonation or premature wear/damage upon tear down following numerous runs. The stock factory internal components held up well to the low boost levels, most likely due to the use of a decent intercooler and reasonable tune. The total build costs (including freshening up the engine) was under $2000. You cannot build a performance NA engine for that.

This was encouraging to see. That is what I hope to find with my "Turbo X" build; around 50% increases in torque and HP, with broad flat curves, at street friendly RPMs. I think that should make for a decent 'driver' X, what it should have had from the factory.

Jonohhh

True Classic

Honestly I don't know if there are the same E85 issues here with the percentage of alcohol. As I said, I haven't looked into it before. But I wonder if the "flex-fuel" sensors can detect the differences and signal the ECU to tune accordingly? That's what those sensors are for on production vehicles, but I don't know how accurate or sensitive they are.

View attachment 61822

And yes, 2.3 bar is a lot of boost.

Old post I happened to miss, but; Easy peasy, these are commonly used in the aftermarket on many standalone ecus, and even on some OEM ecus that have custom code to support an ethanol content input. Accuracy is typically in the realm of +/-5%, and 1% is a pretty typical resolution, both of which are more than enough.

Typically, these communicate two things - fuel temperature, and alcohol content.

And, at least on the Delphi or Continental units I've seen, they output each distinctly by varying the output frequency based on alcohol content, and the pulse width based on fuel temperature.

If you use an ECU which doesn't natively support this, you can buy off the shelf boxes which convert the sensors output to an analog 0-5V output, which most ecus can then use to blend between either two fuel tables, or interpolate along a table for the stoichiometric value of the fuel based on the alcohol content (or both ideally). Alternatively, with some coding and an ESP32, one could make their own translator as well.

As far as the recent findings - those are some encouraging numbers from what is undoubtedly a malaise era lump. I'm exited to see how a stock form 1500 responds to some boost

Last edited:

Dr.Jeff

True Classic

Thanks for the Flex Fuel sensor info. The ECU I'll be using does support it but I haven't decided to go that route yet. I really like the advantages of E85 with a boosted application, but E85 is not widely available around here. And I've already acquired some components for my build that are not fully E85 compatible. I can always change a few components and add it later.Old post I happened to miss, but; Easy peasy, these are commonly used in the aftermarket on many standalone ecus, and even on some OEM ecus that have custom code to support an ethanol content input. Accuracy is typically in the realm of +/-5%, and 1% is a pretty typical resolution, both of which are more than enough.

Typically, these communicate two things - fuel temperature, and alcohol content.

And, at least on the Delphi or Continental units I've seen, they output each distinctly by varying the output frequency based on alcohol content, and the pulse width based on fuel temperature.

If you use an ECU which doesn't natively support this, you can buy off the shelf boxes which convert the sensors output to an analog 0-5V output, which most ecus can then use to blend between either two fuel tables, or interpolate along a table for the stoichiometric value of the fuel based on the alcohol content (or both ideally). Alternatively, with some coding and an ESP32, one could make their own translator as well.

As far as the recent findings - those are some encouraging numbers from what is undoubtedly a malaise era lump. I'm exited to see how a stock form 1500 responds to some boost. I think it'll surprise us.

Regarding the turbo tests I mentioned. I agree their results were quite encouraging for such a underwhelming engine. Especially since the SOHC is another one.

Bjorn Nilson

True Classic

I agree. The fuel consumption with the UT engine is much less compared to the 1500 when driving normally. Of course, the smaller displacement, injectors, perfect ignition, and air/fuel mixture help, but anyway. However, when driving hard the consumption easily doubles.On a somewhat related note, I also recall another test to see how adding a small turbo onto a 4-cyl engine affected fuel mileage compared to the same vehicle without the turbo. Interesting it actually improved fuel mileage under normal driving conditions (i.e. around town, not driven particularly hard). However if driven aggressively or under higher loads then the mileage was lower than the NA version.

I think you should give up the idea of going flexi fuel. There is no meaning with it with the low boost setup you have in mind, unless the price will drop drastically on E85. I also expect the mapping would be more complex. And the fuel sensor is not for free.

Dr.Jeff

True Classic

I completely agree. And that's why I decided against it in the beginning. I guess I am terrified of the possibility of detonation with this particular engine; putting a turbo on a totally stock SOHC with no turbo spec pistons, no oil squirters, no special valves, etc. But your point about low boost is excellent. Plus I am doing a few other things to help manage thermal loads, which will also deter detonation. So I'll see how things go without flex fuel first. But I must admit it would be fun to be able to turn up the boost more with running E85.I think you should give up the idea of going flexi fuel. There is no meaning with it with the low boost setup you have in mind, unless the price will drop drastically on E85. I also expect the mapping would be more complex. And the fuel sensor is not for free.

Dr.Jeff

True Classic

I don't know where the limits are for these engines, but adding boost completely changes things when it comes to knock.I'm curious at what point the 1500 even becomes knock limited. I don't believe it reaches knock before mean best torque at 100kpa manifold pressure, certainly at some level of boost that'll change though....but just how much before it reaches that point?

Bjorn Nilson

True Classic

I know some people turboed the Ford Probe V6 (Mazda KL engine) on stock internals and that one has a 9.2:1 compression. I also think the Volvo 745 with the "LT" turbo had a quite high compression ratio. So it is probably just a question about how much boost you put on it. I think you easily would reach 130-140hp with a modest boost on a 1500 without risk for detonation (with gas). Turn to an expert for mapping and allow several hours on the Dyno to get it right.

Have you thought about having a thicker head gasket to reduce compression? That's the way many BMW tuners do it here.

Have you thought about having a thicker head gasket to reduce compression? That's the way many BMW tuners do it here.

Dr.Jeff

True Classic

I did some research on the subject of compression ratio and boost (in this case I'm referring to the static CR as a baseline, then determining the dynamic CR with boost). Like everything else, it depends on a lot of variables. But my view with the SOHC is the stock static compression for a US spec head* (around 8.2:1) is almost too low, even with up to 10 psi boost (*keep in mind we got the low compression head vs the "Euro spec" head you have over there). I plan to use a MLS head gasket to help with reliability. And they can be ordered in any desired thickness (they just add or subtract layers of steel). Therefore I think I may order a thinner one to increase the static CR. However I have not ordered the gasket yet because I want to do some calculations to determine how much the static CR (and therefore the boosted dynamic CR) will change as the gasket thickness varies.Have you thought about having a thicker head gasket to reduce compression? That's the way many BMW tuners do it here.

lookforjoe

True Classic

I have no qualms adding a turbo to the Volvo NA redblocks - similar (antique) SOHC design, relatively low static CR, iron block - but.. the Volvo motors have strong internal components. I'm not sure the stock Fiat rods etc., would hold up. On the other hand if it's a small turbo & boost is kept under .5bar, it could well be just fine, if fueling & ignition are handled properly. I watch my Wideband controller like a hawk - using stock EMS, there are several spots in the powerband where it can go very lean under low boost, so I have to modulate throttle & manually shift the auto trans to avoid those areas.

Bjorn Nilson

True Classic

A lot of people are putting turbo on the Volvo redblocks here but I've never seen anyone going "mild". Most people aim for +350hp and then stock internals are to weak. Common upgrades are forged rods and pistons but also the crank is commonly upgraded. I think all of these components (except the pistons) are forged on the 1500 SOHC and would handle the extra load better than the Redblock. A correct tuning and the ECU is the most important to prevent disaster. I discussed having a cheap Megasquirt ECU in my 128SL with my tuner, but he strongly advised me to go for a MaxxECU or an EcuMaster because the quality, precision, tuning and data logging capabilities etc. are so much better. -You pay for what you get.

Dr.Jeff

True Classic

My experience with early VW engines (e.g. the "JH") is what lead to this Fiat turbo project. Also a similar design, and with very robust internals, the VW engine can handle quite a bit of boost (relatively) with all stock components. Honestly I have no idea just how robust the Fiat internals really are; Fiat enthusiasts seem to think the engine came directly from God and is perfect in every way, therefore it can handle anything. I'm not one of those people. But I tend to agree with Bjorn, the crank and rods are forged so they should be fine. To me the weak links are the pistons and valves. However the pistons have incredibly thick top ring landings and are overall fairly heavy, so they might do o.k. The valves are a different story. But SS stock replacements are available if they prove to be unable to handle the heat. The keys for my build are exactly what you said; keep the boost low (around .6 bar), and use a conservative tune. Combined with plenty of thermal management, detonation should remain in check.I have no qualms adding a turbo to the Volvo NA redblocks - similar (antique) SOHC design, relatively low static CR, iron block - but.. the Volvo motors have strong internal components.

Dr.Jeff

True Classic

Back in post #484 I described a story I saw with a very similar turbo plan to my "turbo X" project. Namely, building a conservative, low boost turbo setup on a relatively stock engine to provide a reasonable improvement in power output at a reasonable cost. In that instance it was based on a American V8 engine. Admittedly that is a very different design from the X's SOHC. But today I came across another such story, this time on something a little closer to home. The engine choice in this case was a single overhead cam, two valve per cylinder, inline design from the same era as our SOHC and utilizing the same basic Bosch FI system as the later X's. The main difference being it was a straight 6 cylinder instead of a four, with about twice the displacement.

They started with a freshly rebuilt, completely stock BMW 3.8L naturally aspirated engine. These are a low compression, iron block/aluminum head configuration with very similar component materials (crank, pistons, rods, valves, etc) as the SOHC. The factory ECU was replaced with a aftermarket standalone (tunable) item, otherwise things were pretty much left stock. It was dyno tested in NA mode first, then dyno tested again after installing a simple turbo setup, all on regular pump gas.

At five pounds of boost it gained 40% in HP and torque over the NA runs. And at 10 PSI it gained 75% in HP and torque over NA. The dyno curves in "boost" mode had about the same profile as those in NA mode. Meaning the power improvements were realized across the RPM range, and not a "peaky" spike at redline like you will see in a highly built NA performance engine. That is an impressive gain at 10 PSI! Even with the very low power figures the stock SOHC has, anything close to a 75% increase would be incredible. Far more than you will achieve with a very highly modified NA SOHC, at a lower cost, and with greater reliability.

In reality I would not expect to see as much of an improvement when boosting the X's engine as they achieved on the BMW. Despite being a very similar overall design, the BMW engine is much more efficient than the SOHC. And the more efficient the engine, the greater the gains to be found with boost. But nonetheless it was quite encouraging to see how well this plan worked once again on another engine - this one even closer to ours than the first example (post #484).

They started with a freshly rebuilt, completely stock BMW 3.8L naturally aspirated engine. These are a low compression, iron block/aluminum head configuration with very similar component materials (crank, pistons, rods, valves, etc) as the SOHC. The factory ECU was replaced with a aftermarket standalone (tunable) item, otherwise things were pretty much left stock. It was dyno tested in NA mode first, then dyno tested again after installing a simple turbo setup, all on regular pump gas.

At five pounds of boost it gained 40% in HP and torque over the NA runs. And at 10 PSI it gained 75% in HP and torque over NA. The dyno curves in "boost" mode had about the same profile as those in NA mode. Meaning the power improvements were realized across the RPM range, and not a "peaky" spike at redline like you will see in a highly built NA performance engine. That is an impressive gain at 10 PSI! Even with the very low power figures the stock SOHC has, anything close to a 75% increase would be incredible. Far more than you will achieve with a very highly modified NA SOHC, at a lower cost, and with greater reliability.

In reality I would not expect to see as much of an improvement when boosting the X's engine as they achieved on the BMW. Despite being a very similar overall design, the BMW engine is much more efficient than the SOHC. And the more efficient the engine, the greater the gains to be found with boost. But nonetheless it was quite encouraging to see how well this plan worked once again on another engine - this one even closer to ours than the first example (post #484).

Sakke

Low Mileage

Hi guys,

Not exactly related to X1/9 turbo systems but we are talking about the same basic engine anyway.

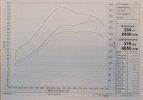

This was the dyno result on a hot day way back in 2005 with my 1520cc SOHC turbo engine installed in 4-door Fiat Uno. Talking about the perfect car for the whole family.

I added flow bench measurement results for the modified head as well in case you are interested. Text is in Finnish, sorry. Dated 1999, how time flies :0)

Specs were:

Original engine: 1498cc Fiat Regata/Ritmo (bore 86,4mm, stroke 63,9mm)

Piston oil squirters added to the block

1.0mm removed from block top surface

Space for copper fire rings machined to the block (otherwise original thin head gasket used)

Custom CrMo 120mm conrods (same length as 1116cc engine rods)

VW Beetle Mahle 87mm pistons with Total Seal gapless rings

Ported head with stainless 40/35mm valves

Cam 280°/110°/10,7mm

500cc injectors

58mm throttle body from SAAB 9000

Intercooler 440x280x50mm

Modified Switcher S1BG turbo with ported and enlarged wastegate, 46mm compressor and 48mm turbine wheel diameter

Mild steel tubular exhaust manifold

Max. boost pressure when peaking 1,3-1,1bar (19-16psi)

Old programmable 16-bit ECU system called Hestec

98oct pump gas (93 in US terms)

Not exactly related to X1/9 turbo systems but we are talking about the same basic engine anyway.

This was the dyno result on a hot day way back in 2005 with my 1520cc SOHC turbo engine installed in 4-door Fiat Uno. Talking about the perfect car for the whole family.

I added flow bench measurement results for the modified head as well in case you are interested. Text is in Finnish, sorry. Dated 1999, how time flies :0)

Specs were:

Original engine: 1498cc Fiat Regata/Ritmo (bore 86,4mm, stroke 63,9mm)

Piston oil squirters added to the block

1.0mm removed from block top surface

Space for copper fire rings machined to the block (otherwise original thin head gasket used)

Custom CrMo 120mm conrods (same length as 1116cc engine rods)

VW Beetle Mahle 87mm pistons with Total Seal gapless rings

Ported head with stainless 40/35mm valves

Cam 280°/110°/10,7mm

500cc injectors

58mm throttle body from SAAB 9000

Intercooler 440x280x50mm

Modified Switcher S1BG turbo with ported and enlarged wastegate, 46mm compressor and 48mm turbine wheel diameter

Mild steel tubular exhaust manifold

Max. boost pressure when peaking 1,3-1,1bar (19-16psi)

Old programmable 16-bit ECU system called Hestec

98oct pump gas (93 in US terms)

Attachments

Last edited:

myronx19

True Classic

Oil cooling question - where would the best place to mount a cooler be?

I have a filter sandwich and will buy a Stebro small cooler - but I'm trying to figure out the best placement it. The side scoops don't bring in a lot of air (I've tested them) - They need airflow of course.

Any examples of a small oil cooler? (Maybe it's been discussed in the thread - need to find it!)

I have a filter sandwich and will buy a Stebro small cooler - but I'm trying to figure out the best placement it. The side scoops don't bring in a lot of air (I've tested them) - They need airflow of course.

Any examples of a small oil cooler? (Maybe it's been discussed in the thread - need to find it!)

Dr.Jeff

True Classic

I agree with you, the side scoops really don't bring in enough air to effectively supply a oil cooler. And the engine bay in general is rather hot without much overall air flow either. Although I know it has been done, I would not recommend mounting the oil cooler at the front of the car; the incredibly long oil lines to and from it would over tax the oil pump and cause a huge delay in circulation through the system. Plus any drain back will cause a long delay in oil feed upon start up. Perhaps if it is a dedicated race car where the vehicle is in constant motion and the engine is at constant redline, then a front mounted oil cooler might work. But not on a street car. Likewise, mounting it at the rear of the car still requires fairly long oil lines, plus there isn't a ton of air flow back there either. This makes the placement of a oil cooler difficult. Ideally you can keep the lines as short as possible. Same for the remotely mounted oil filter.Oil cooling question - where would the best place to mount a cooler be?

I have a filter sandwich and will buy a Stebro small cooler - but I'm trying to figure out the best placement it. The side scoops don't bring in a lot of air (I've tested them) - They need airflow of course.

Any examples of a small oil cooler? (Maybe it's been discussed in the thread - need to find it!)

In my case I am mounting the turbo's intercooler and the oil cooler in the engine bay, but I have a electric fan dedicated to them. The intercooler lays flat at the top of the bay, toward the left side above the tail of the transmission. The fan mounts directly under the intercooler. Then the oil cooler mounts under the fan. So both coolers get plenty of air flow from the fan. Then the air is ducted through the engine bay to help circulate and remove the hot air from the area. So one fan actually serves three purposes.

There are oil coolers with a small electric fan attached to them. Or you can add one to any cooler. That might be the best option, and will allow you to mount it almost anywhere.

As for the type of oil cooler to use. I prefer the "stacked plate" style. They offer the most efficient heat transfer with least oil flow restriction. There's a common size with 8 plates that would work well for these engines.

Bjorn Nilson

True Classic

I have a different opinion. I've modified the inside scoop and built a box to encapsulate the oil cooler to maximize the airflow. I also installed a small fan on top to suck the air if standing still or driving slowly. It works very well and I seldom see temps above 100⁰C.I agree with you, the side scoops really don't bring in enough air to effectively supply a oil cooler.