JNewm

True Classic

I just finished replacing my front pads and rotors (a first!), and although it was not hard, it did have a surprising number of twists and turns. As usual, everyone on here is operating at a level far beyond me--which may help explain why I couldn't find a dumbed-down, step-by-step explainer on here. On the off-chance that anyone else might find this helpful going forward, I figured I'd put together an "X1/9 Brake Jobs for Dummies"-level walk-through.

The Workshop Manual explains how to disassemble everything. So I won't walk through that. Just remove the wheel and spacer, pull the cotter pins out of the sliding lock wedges, tap the wedges out with a hammer and some kind of drift (I used the tip of a needlenose pliers held sideways against the wedge), work the caliper free and hang it from something, remove the caliper mounting bracket, then remove the rotor.

That was the easy part. But the YouTube videos I'd watched about brake jobs just didn't seem to apply, once I was staring at all the different parts. Turns out the X brakes have a few odd wrinkles to them.

Shopping List

Rotors

Brake pads (I used MWB's semi-metallic. Ceramic pads are available from big parts stores--apparently less dusty, but not as good at stopping.)

Replacement sliding lock wedges (optional, I used the later Bertone-style wedges, available from MWB)

Replacement anti-rattle springs (optional)

Replacement cotter pins for lock wedges (optional)

Replacement rubber nipples for bleed screws (optional)

Silicone lubricant (I used Sil-Glyde, available here)

Anti-seize

High-temp spray paint if painting calipers, dust shields, rotors, etc.

The Job Itself

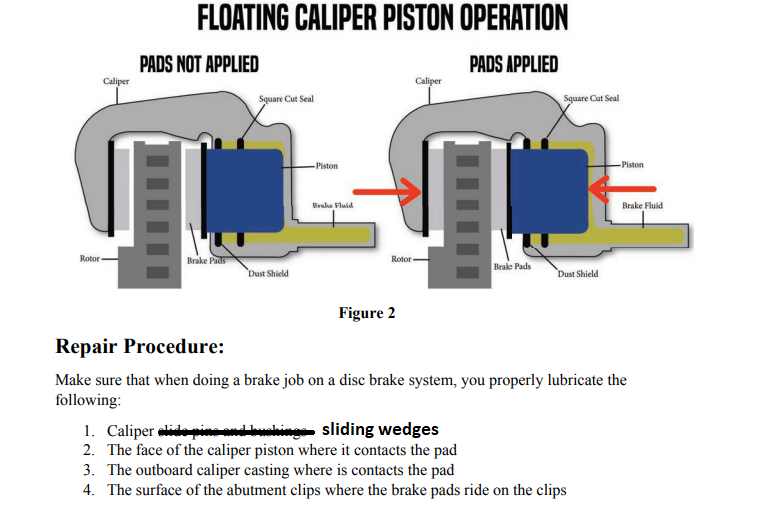

As a starting point, I found this diagram helpful for explaining how floating, single-piston calipers work:

You can find conflicting advice about whether to lubricate using anti-seize or silicone paste/lube. Both a NAPA explainer and the consensus on an r/mechanics thread said do not use anti-seize on any moving parts. Anti-seize can be used on the hub-to-rotor surface, but that's about it. Use silicone lubricant for everything else.

So after everything is disassembled, I'd start by applying anti-seize to the hub.

Next, you can see why applying a layer of silicone to the backs of the pads is important by comparing the old to the new:

It's very important that the caliper itself be able to slide back and forth, so that both pads actually "pinch" the rotor (see diagram above). When I disassembled my brakes, the sliding lock wedges had oxidized to the calipers. I'm pretty sure the calipers weren't sliding. So while everything is disassembled, examine the part of the calipers where the wedges press into place and clean if necessary. (And if you're painting the calipers, don't paint the mating surface like I did. If you already did that, time to bust out the 400-grit and start sanding.) Apply a thin layer of silicone lubricant to both the caliper surface and the locking wedges.

If you already did that, time to bust out the 400-grit and start sanding.) Apply a thin layer of silicone lubricant to both the caliper surface and the locking wedges.

As noted, I used the later-style sliding wedges. You can see the difference below. They're longer and supposedly better. I figured some engineer who's much smarter than I am made the design change for *some* reason, so why not go with the later ones. They also only require one cotter pin clip, which is nice.

Now you're ready to start reinstalling everything. First, reinstall the dust shield if you took that off to paint it. Don't forget to tighten the little screw all the way before mounting the rotor. I think it's okay to apply a light coat of spray paint to the hub.

Next install the rotor. You can paint the areas I painted here, since they don't rub on the pads.

Next install the caliper mounting bracket. I put some thread locker (blue Loctite) on the bolts. Remember that the bolts should be pushed through from the "back," i.e., the side of the bracket that you can't see normally, on the inboard wheel-well side.. Torque them to 35 ft./lbs.

Apply a thin layer of silicone lubricant on the mounting bracket mating surfaces on which the pads slide back and forth, being careful not to get any on the pad surfaces or on the rotor. If you haven't already, lubricate the backs of the pads and install.

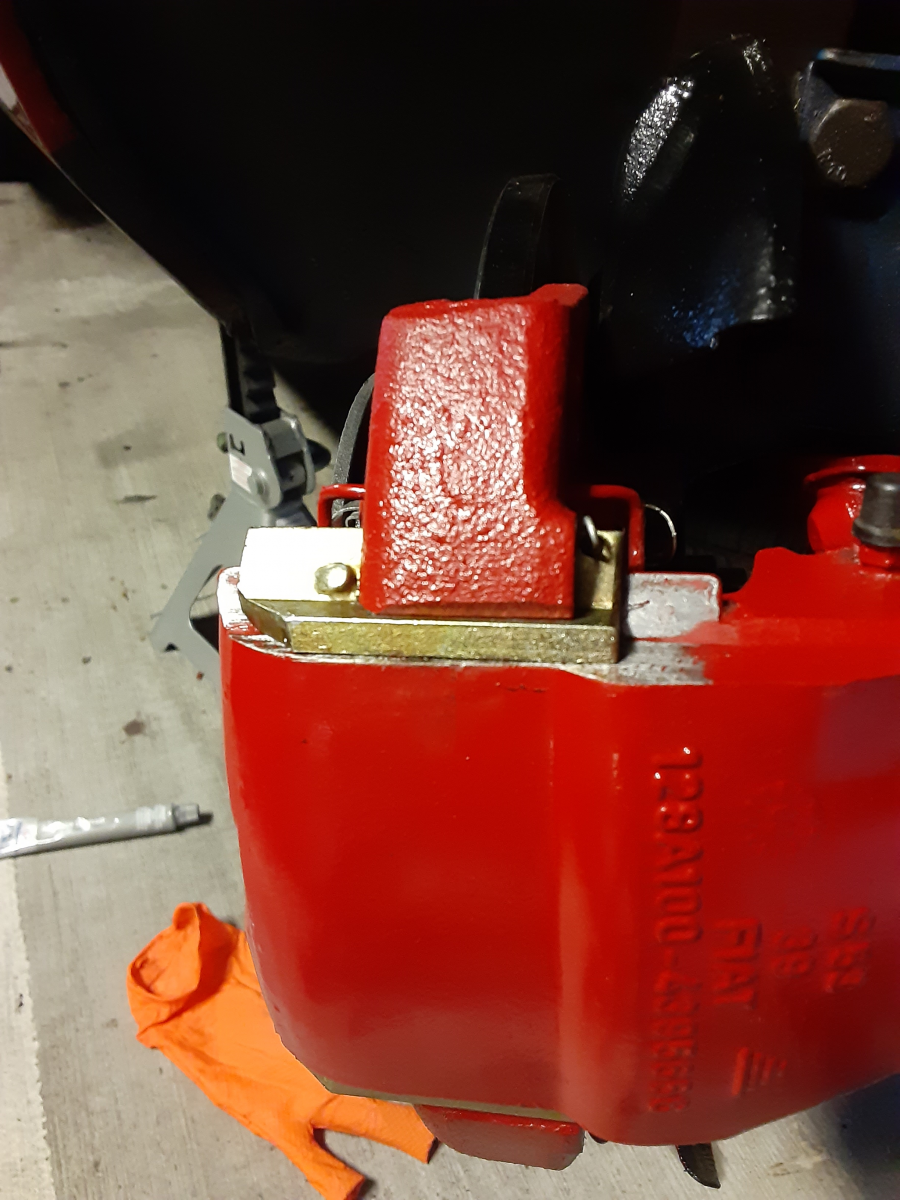

Compress the brake piston with a C-clamp or compressor tool. Slide the calipers into place. You can see in this photo where I accidentally painted the caliper-to-sliding-wedge mating surface and had to sand it down.

Next install the sliding wedges. They are pretty damn snug in there, so I found it helpful to use a Quick-Grip clamp to squeeze the caliper against the bracket to make enough room to get the wedge started. Don't try to just force/pound them in. The caliper is aluminum, so it's super soft and can gouge easily. I used one of the old wedges as a drift to tap the new ones in. Once it's in, install the cotter pin clip.

(This also gives a better view of where you should apply lubricant to the caliper, but should not apply paint )

)

Done!

And there you have it! Even on a short test-drive in the garage, I found that stopping power was increased and pedal feel was much better. A lot of that was likely due to the calipers having formerly been stuck in place, but now being able to move freely.

And as a bonus: pretty calipers. The automotive equivalent of Louboutin's famous red-soled heels.

The Workshop Manual explains how to disassemble everything. So I won't walk through that. Just remove the wheel and spacer, pull the cotter pins out of the sliding lock wedges, tap the wedges out with a hammer and some kind of drift (I used the tip of a needlenose pliers held sideways against the wedge), work the caliper free and hang it from something, remove the caliper mounting bracket, then remove the rotor.

That was the easy part. But the YouTube videos I'd watched about brake jobs just didn't seem to apply, once I was staring at all the different parts. Turns out the X brakes have a few odd wrinkles to them.

Shopping List

Rotors

Brake pads (I used MWB's semi-metallic. Ceramic pads are available from big parts stores--apparently less dusty, but not as good at stopping.)

Replacement sliding lock wedges (optional, I used the later Bertone-style wedges, available from MWB)

Replacement anti-rattle springs (optional)

Replacement cotter pins for lock wedges (optional)

Replacement rubber nipples for bleed screws (optional)

Silicone lubricant (I used Sil-Glyde, available here)

Anti-seize

High-temp spray paint if painting calipers, dust shields, rotors, etc.

The Job Itself

As a starting point, I found this diagram helpful for explaining how floating, single-piston calipers work:

You can find conflicting advice about whether to lubricate using anti-seize or silicone paste/lube. Both a NAPA explainer and the consensus on an r/mechanics thread said do not use anti-seize on any moving parts. Anti-seize can be used on the hub-to-rotor surface, but that's about it. Use silicone lubricant for everything else.

So after everything is disassembled, I'd start by applying anti-seize to the hub.

Next, you can see why applying a layer of silicone to the backs of the pads is important by comparing the old to the new:

It's very important that the caliper itself be able to slide back and forth, so that both pads actually "pinch" the rotor (see diagram above). When I disassembled my brakes, the sliding lock wedges had oxidized to the calipers. I'm pretty sure the calipers weren't sliding. So while everything is disassembled, examine the part of the calipers where the wedges press into place and clean if necessary. (And if you're painting the calipers, don't paint the mating surface like I did.

As noted, I used the later-style sliding wedges. You can see the difference below. They're longer and supposedly better. I figured some engineer who's much smarter than I am made the design change for *some* reason, so why not go with the later ones. They also only require one cotter pin clip, which is nice.

Now you're ready to start reinstalling everything. First, reinstall the dust shield if you took that off to paint it. Don't forget to tighten the little screw all the way before mounting the rotor. I think it's okay to apply a light coat of spray paint to the hub.

Next install the rotor. You can paint the areas I painted here, since they don't rub on the pads.

Next install the caliper mounting bracket. I put some thread locker (blue Loctite) on the bolts. Remember that the bolts should be pushed through from the "back," i.e., the side of the bracket that you can't see normally, on the inboard wheel-well side.. Torque them to 35 ft./lbs.

Apply a thin layer of silicone lubricant on the mounting bracket mating surfaces on which the pads slide back and forth, being careful not to get any on the pad surfaces or on the rotor. If you haven't already, lubricate the backs of the pads and install.

Compress the brake piston with a C-clamp or compressor tool. Slide the calipers into place. You can see in this photo where I accidentally painted the caliper-to-sliding-wedge mating surface and had to sand it down.

Next install the sliding wedges. They are pretty damn snug in there, so I found it helpful to use a Quick-Grip clamp to squeeze the caliper against the bracket to make enough room to get the wedge started. Don't try to just force/pound them in. The caliper is aluminum, so it's super soft and can gouge easily. I used one of the old wedges as a drift to tap the new ones in. Once it's in, install the cotter pin clip.

(This also gives a better view of where you should apply lubricant to the caliper, but should not apply paint

Done!

And there you have it! Even on a short test-drive in the garage, I found that stopping power was increased and pedal feel was much better. A lot of that was likely due to the calipers having formerly been stuck in place, but now being able to move freely.

And as a bonus: pretty calipers. The automotive equivalent of Louboutin's famous red-soled heels.