You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

X1/9 Brake Job for Dummies

- Thread starter JNewm

- Start date

Dr.Jeff

True Classic

I've never noticed the difference. But all of my X's are 1500's, so would they all be the later type? I'm assuming the "early" ones must be from the calipers used on the real early 1300?The larger late ones have much more sliding surface area and only use the one ‘cotter’ type pin.

DanielForest

True Classic

From Midwest Bayless website, it seems the change occured after 1984.

Dr.Jeff

True Classic

Something else I did not know. Thanks for the info guys.

Apparently all of mine are the "early" style because I don't recall seeing that longer version before. Including on my '85 and '86 X's. But there's no telling how many times the calipers have been replaced on the cars, or with what. So they might of had the longer versions initially - but no longer do.

Apparently all of mine are the "early" style because I don't recall seeing that longer version before. Including on my '85 and '86 X's. But there's no telling how many times the calipers have been replaced on the cars, or with what. So they might of had the longer versions initially - but no longer do.

JNewm

True Classic

This should probably go in my "Basic Brake Job Questions" thread, but I suspect the answer will be helpful to at least one "dummy" (me), and perhaps some future beginner-level DIY'ers.

When you're disconnecting a flexible brake line, are you supposed to disconnect it first from the caliper? Then from the hard brake line?

I'm working on the rear brakes now. I managed to get one of the 10mm nuts on the hard lines loose (driver side). But then as I was loosening it, I realized I was either twisting the hard brake line (if I loosened the 10mm nut) or twisting the flexible brake line (if I loosened the 17mm nut). I decided to try the latter, as I plan to replace the flex line anyway. I loosened it until the flex line was so kinked up that I couldn't loosen anymore, but it wasn't enough to get the line off. So now I'm thinking maybe the idea is to loosen the (15mm?) nut holding the flex line onto the caliper *first*. Then the flex line could just spin as I loosen the 17mm nut holding it to the hard line, instead of kicking up.

Basically I've been going off the rebuild walk-through posted earlier in this thread, and I'm wondering whether to take the following step in red first:

Disconnect Brake Line- Using a 15 mm(?) open-end wrench, loosen and separate lower flexible brake line connection from caliper. Using a 10 mm flare nut wrench, loosen and separate upper brake line connection. Cap line to prevent leakage. * Note: If the flare nut does not come off readily, STOP!!! Shoot some penetrating oil into the threads and wait until it moves. You can use heat, as well but do not mangle the compression fitting nut! Patience is rewarded here!

When you're disconnecting a flexible brake line, are you supposed to disconnect it first from the caliper? Then from the hard brake line?

I'm working on the rear brakes now. I managed to get one of the 10mm nuts on the hard lines loose (driver side). But then as I was loosening it, I realized I was either twisting the hard brake line (if I loosened the 10mm nut) or twisting the flexible brake line (if I loosened the 17mm nut). I decided to try the latter, as I plan to replace the flex line anyway. I loosened it until the flex line was so kinked up that I couldn't loosen anymore, but it wasn't enough to get the line off. So now I'm thinking maybe the idea is to loosen the (15mm?) nut holding the flex line onto the caliper *first*. Then the flex line could just spin as I loosen the 17mm nut holding it to the hard line, instead of kicking up.

Basically I've been going off the rebuild walk-through posted earlier in this thread, and I'm wondering whether to take the following step in red first:

Disconnect Brake Line- Using a 15 mm(?) open-end wrench, loosen and separate lower flexible brake line connection from caliper. Using a 10 mm flare nut wrench, loosen and separate upper brake line connection. Cap line to prevent leakage. * Note: If the flare nut does not come off readily, STOP!!! Shoot some penetrating oil into the threads and wait until it moves. You can use heat, as well but do not mangle the compression fitting nut! Patience is rewarded here!

Dr.Jeff

True Classic

The hard line has a "nut" on the end that goes into whatever is next (e.g. flex hose). That nut is supposed to spin (rotate) on the hardline as it looses or tightens. Therefore turning the nut should not twist the hardline nor the flex hose - if you are securing the fitting on the end of the flex hose at the same time. However the nut has a tendency to get hung up on the hardline. Especially if the hardline is kinked, bent, curved, orovaled, corroded, or otherwise compromised. So start by trying to clean up around the nut and the hardline, then see if it will turn without twisting the hardline.

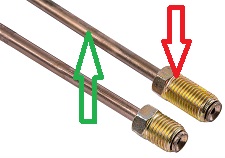

The nut (red arrow) should turn/spin around the line (green arrow) without twisting it:

The nut (red arrow) should turn/spin around the line (green arrow) without twisting it:

Dr.Jeff

True Classic

I've found the biggest problem with the X's brake and clutch lines are the nuts getting frozen/corroded into whatever they go into. So you cannot turn them at all. Often a lot of heat is needed and a really good tool to securely clamp onto the nut while applying considerable force to break it free. So if you were able to turn the nuts at all then you are more than halfway there.

If the hardline is bent right at the back of the nut then it deforms the outer diameter of the line enough to not allow the nut to turn. If that's the case see if you can straighten out the line first.

Removing the caliper from its mounts will also allow you to turn it and remove the hose without the hose twisting. For that matter, if you definitely need to replace the hoses then just cut them. Then things can turn easily.

If the hardline is bent right at the back of the nut then it deforms the outer diameter of the line enough to not allow the nut to turn. If that's the case see if you can straighten out the line first.

Removing the caliper from its mounts will also allow you to turn it and remove the hose without the hose twisting. For that matter, if you definitely need to replace the hoses then just cut them. Then things can turn easily.

JNewm

True Classic

Great point--I'm always reluctant to just cut stuff off, but in this case I have replacement hoses ready to go. Might as well cut 'em off.if you definitely need to replace the hoses then just cut them. Then things can turn easily.

I'd been planning to hold off on replacing the hard lines for a bit, as I try to minimize the "on jackstands" to "on the road" ratio. But I guess maybe I should bite the bullet and do it now. Can you just replace the hard lines up to the rear junction, #7 in the diagram below? Is that fairly easy to get at? I've never replaced hard lines before.

Dr.Jeff

True Classic

If your old lines already got twisted while trying to remove the fittings then there is a decent chance they were damaged. And if you can see a lot of corrosion on the outside then there is a good chance they are shot inside. So replacing them may be a good idea.

That junction (#7) is really easy to get to when the engine/trans are out of the car. It's pretty tight otherwise, but doable. If the lines up to that point are good then there is nothing wrong with only replacing the two from there rearward. Be sure to thoroughly flush/clean the remaining lines before adding the new ones. Personally I would not recommend doing a "splice" somewhere in a brake line, although I know it has been done successively many times. I just prefer to have as few joints as possible. So I think replacing them at the junction block is a good approach.

If you do replace any hardlines, here are a few suggestions (my personal opinions). I would never use a used brake or clutch pipe/line. Brake fluid absorbs water and that causes damage from the inside of the pipe outward. Plus old used lines can accumulate a lot of crud inside them. Furthermore I would not use the stock Fiat lines. They are not easy to work with and in my opinion not the best choice. I prefer using one of the aftermarket copper-nickel products. They are much easier to make, and way more affordable. The lines are a standard US size, but the nuts (fittings) are a very odd size. However they are available (see one of the related threads on that subject for a list of places to get them).

That junction (#7) is really easy to get to when the engine/trans are out of the car. It's pretty tight otherwise, but doable. If the lines up to that point are good then there is nothing wrong with only replacing the two from there rearward. Be sure to thoroughly flush/clean the remaining lines before adding the new ones. Personally I would not recommend doing a "splice" somewhere in a brake line, although I know it has been done successively many times. I just prefer to have as few joints as possible. So I think replacing them at the junction block is a good approach.

If you do replace any hardlines, here are a few suggestions (my personal opinions). I would never use a used brake or clutch pipe/line. Brake fluid absorbs water and that causes damage from the inside of the pipe outward. Plus old used lines can accumulate a lot of crud inside them. Furthermore I would not use the stock Fiat lines. They are not easy to work with and in my opinion not the best choice. I prefer using one of the aftermarket copper-nickel products. They are much easier to make, and way more affordable. The lines are a standard US size, but the nuts (fittings) are a very odd size. However they are available (see one of the related threads on that subject for a list of places to get them).

darwoodious

Darin Nelson

I've found that with old cars like these and corroded nuts & bolts, the best advice is to use penetrating oil and patience - meaning you identify a job and all the nuts/bolts involved and use penetrating oil in them for some 2-3 days before you even tackle the job.

The other option is to do what I have done previously: ham handed forcing of those small rusty bolts, nuts and brake lines and at best strip the nut or worse (and more often) break the stud or bolt off.

Very gentle with rusty nuts and bolts these days...

The other option is to do what I have done previously: ham handed forcing of those small rusty bolts, nuts and brake lines and at best strip the nut or worse (and more often) break the stud or bolt off.

Very gentle with rusty nuts and bolts these days...

JNewm

True Classic

Finally got them loose yesterday night. Lots of B'laster and patience, absolutely right @darwoodious . I think it may have helped that I hit the connections with a wire brush, then yet another round of B'laster. After that round the second one broke loose.

The only remaining "stuck" point is that one nut remains frozen to one of the hard lines. (I already cut the flex hose off and removed it.) Not sure how to unstick that, as I'm wary of clamping with too much force on the hard line to hold it in place while turning the nut. But I plan to replace the hard line anyway. Or, alternatively, I may finally break down and take this to a shop. I don't own a cutter, flare tool, or bender, so I'd have to buy all of 'em. And it looks like good sets are pretty expensive. (Found some cheap ones, but they have terrible reviews.)

The only remaining "stuck" point is that one nut remains frozen to one of the hard lines. (I already cut the flex hose off and removed it.) Not sure how to unstick that, as I'm wary of clamping with too much force on the hard line to hold it in place while turning the nut. But I plan to replace the hard line anyway. Or, alternatively, I may finally break down and take this to a shop. I don't own a cutter, flare tool, or bender, so I'd have to buy all of 'em. And it looks like good sets are pretty expensive. (Found some cheap ones, but they have terrible reviews.)

Hasbro

True Classic

myronx19

True Classic

I used MWB's semi-metallic.

Me as well. They don't create a lot of dust, and they provide good brake feel in my opinion. They seem to have really good life, even though I punish my car regularly

ArtBasement

Erwin Timmers

I don't have a pic with me at the moment, but Matt once sent our club a third or fourth version for our tech workshop: this one had dimples in the surface, presumably to make for additional grease retainage.This photo shows the early ones that were (presumably) original to my 1981 X (top pair) and the "late style" sold by MWB (bottom pair).

View attachment 42562

Dr.Jeff

True Classic

So not only "early/short" and "late/long" versions, but also superseded designs to the late ones?I don't have a pic with me at the moment, but Matt once sent our club a third or fourth version for our tech workshop: this one had dimples in the surface, presumably to make for additional grease retainage.