cozzoi

George

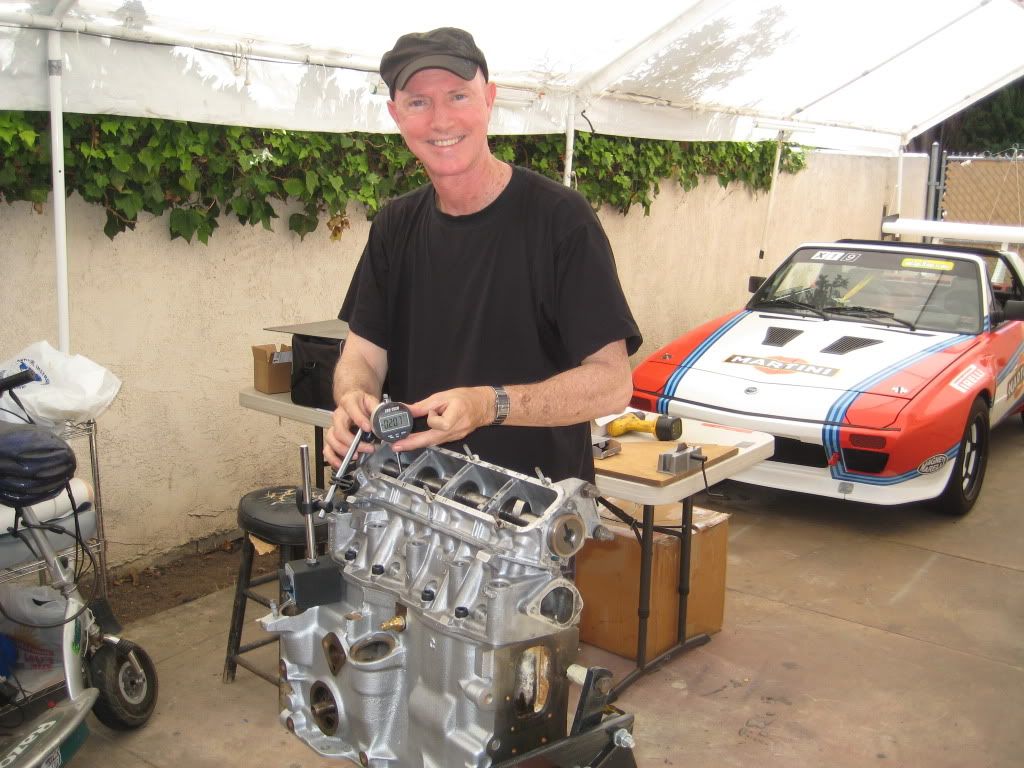

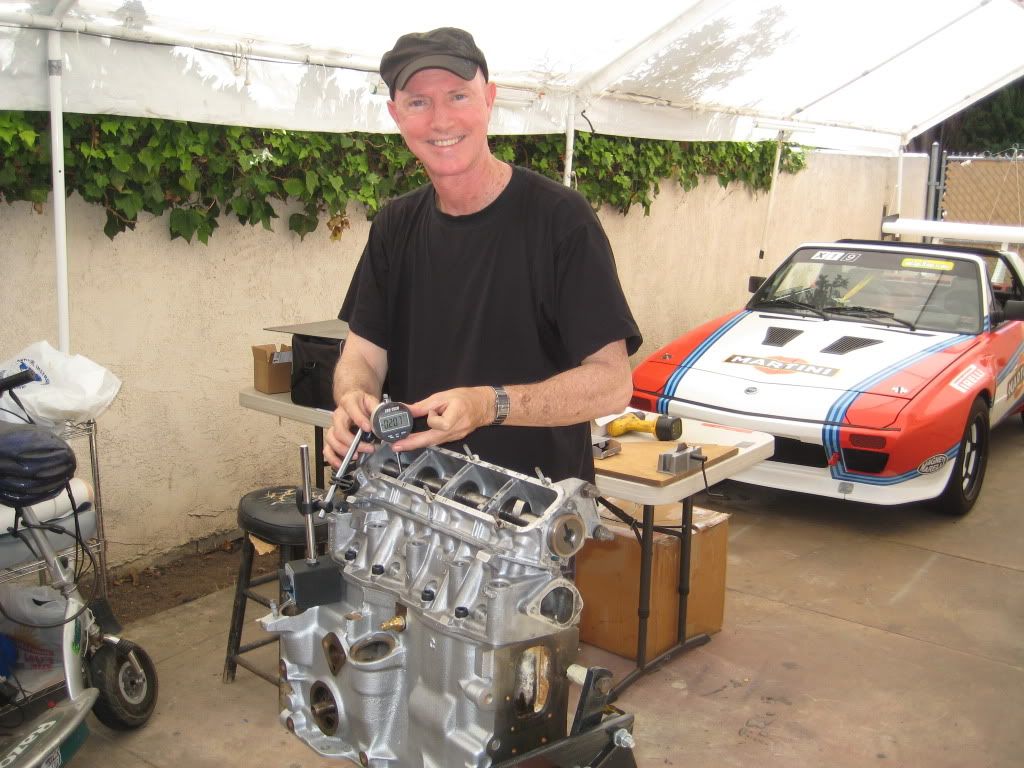

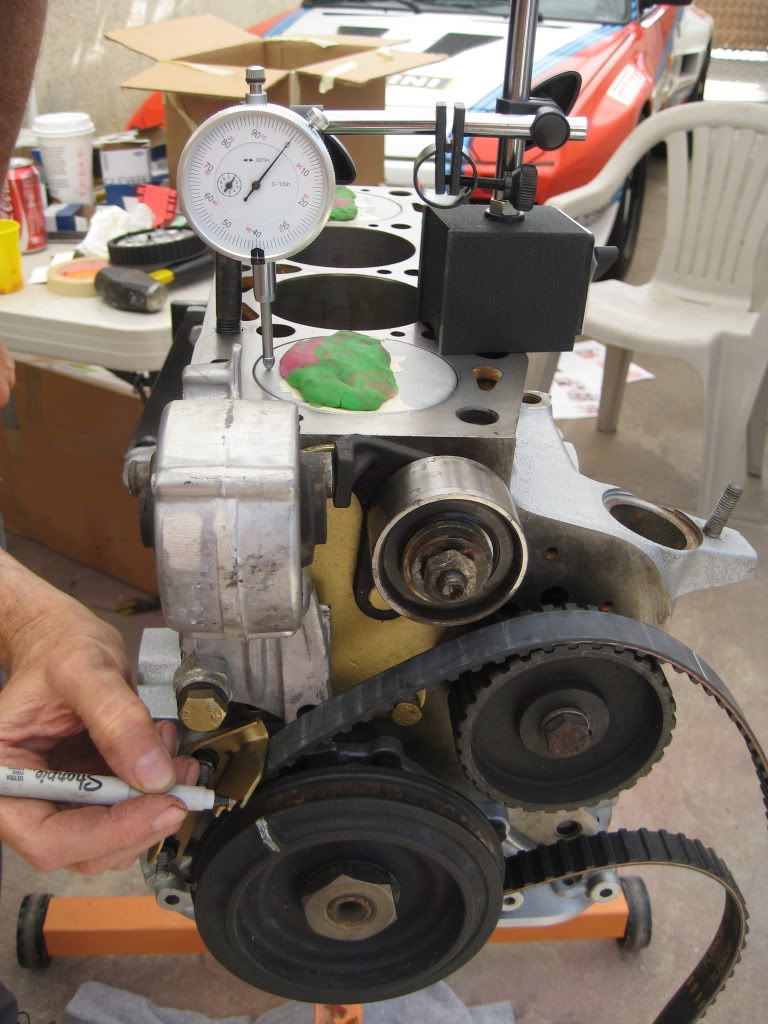

Finally the process begun, I will dedicate one day a week for this project

and will report it weekly with pics

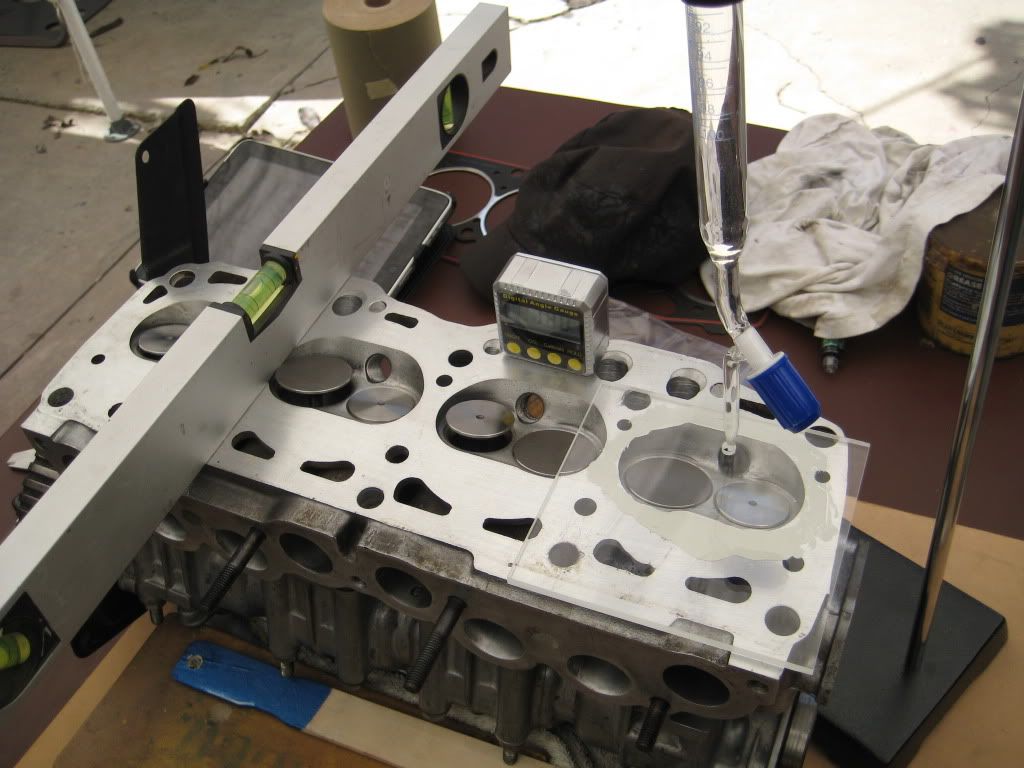

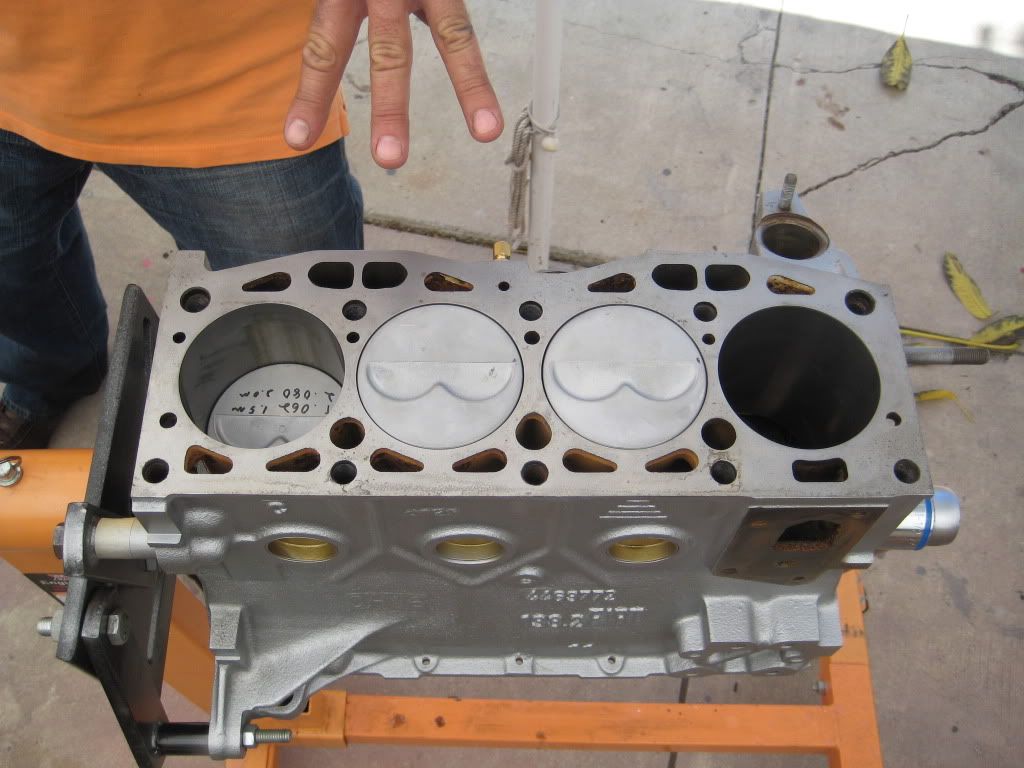

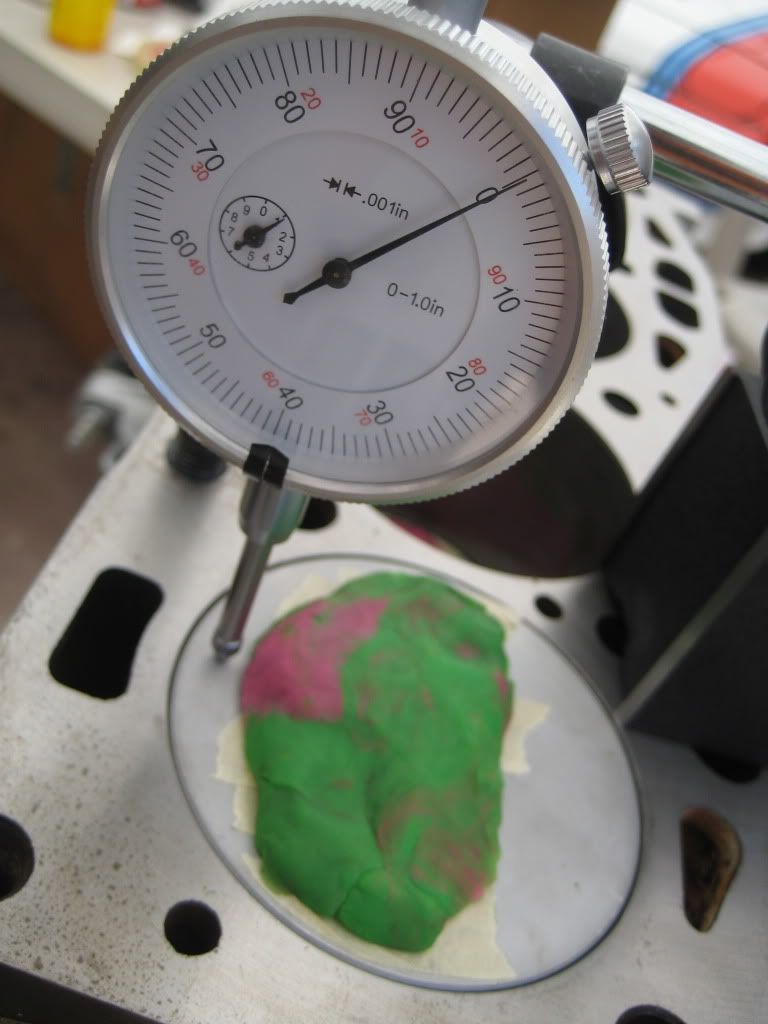

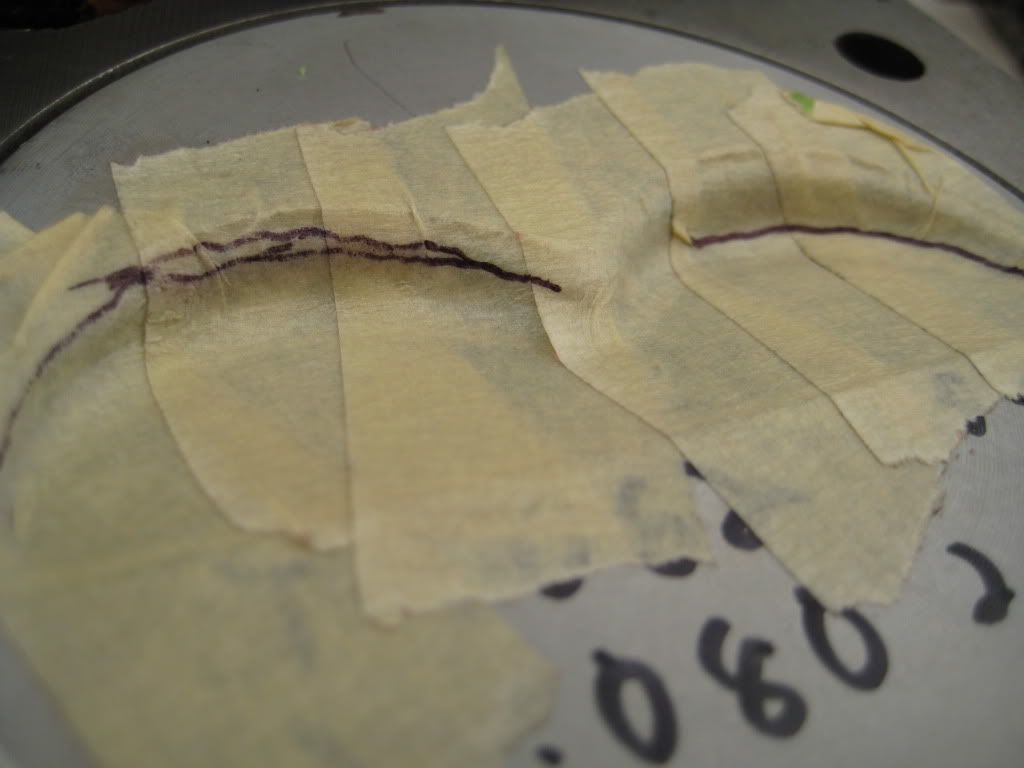

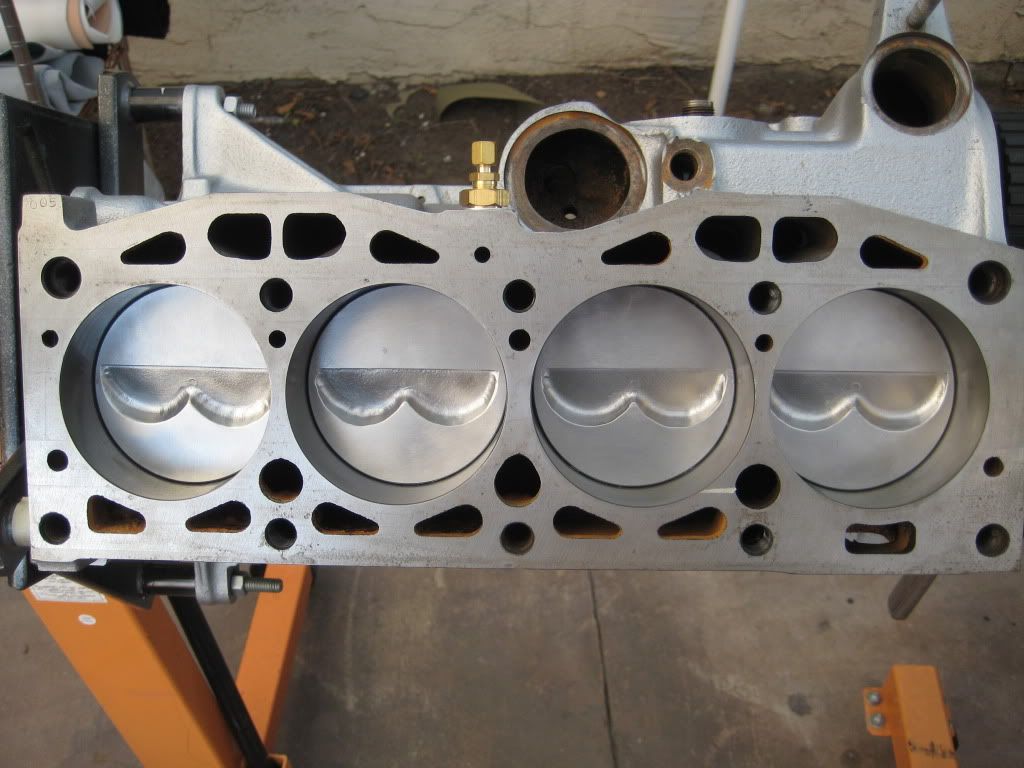

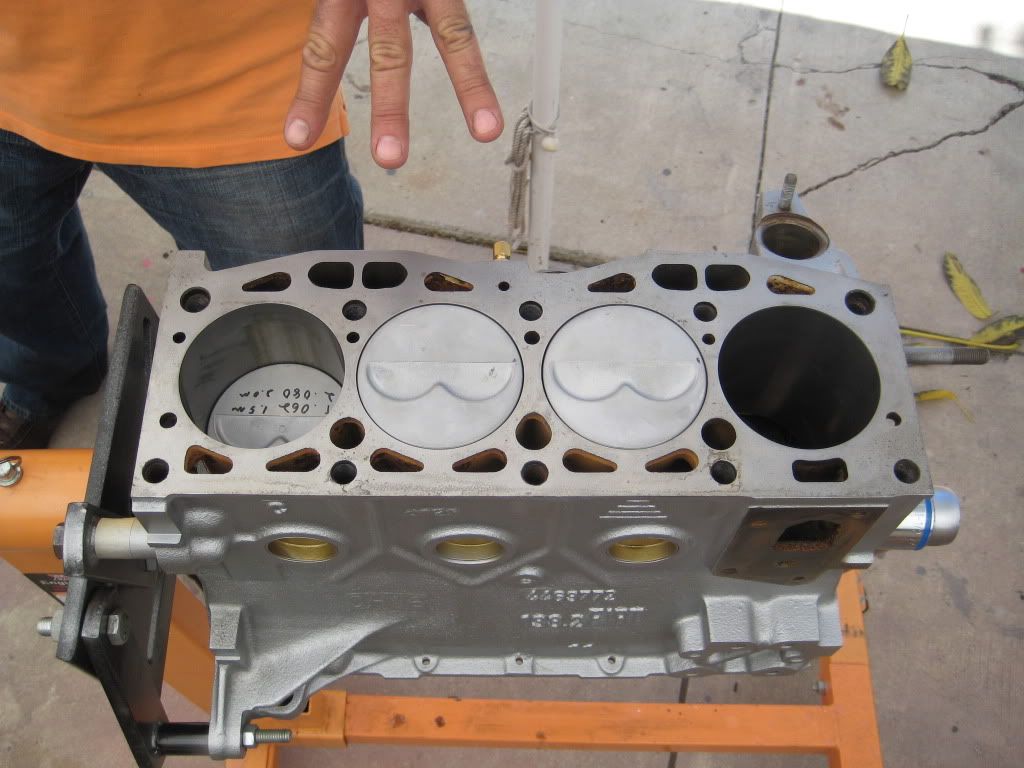

-1500 engine with all standard clearances-done

-cleaned and honed-done

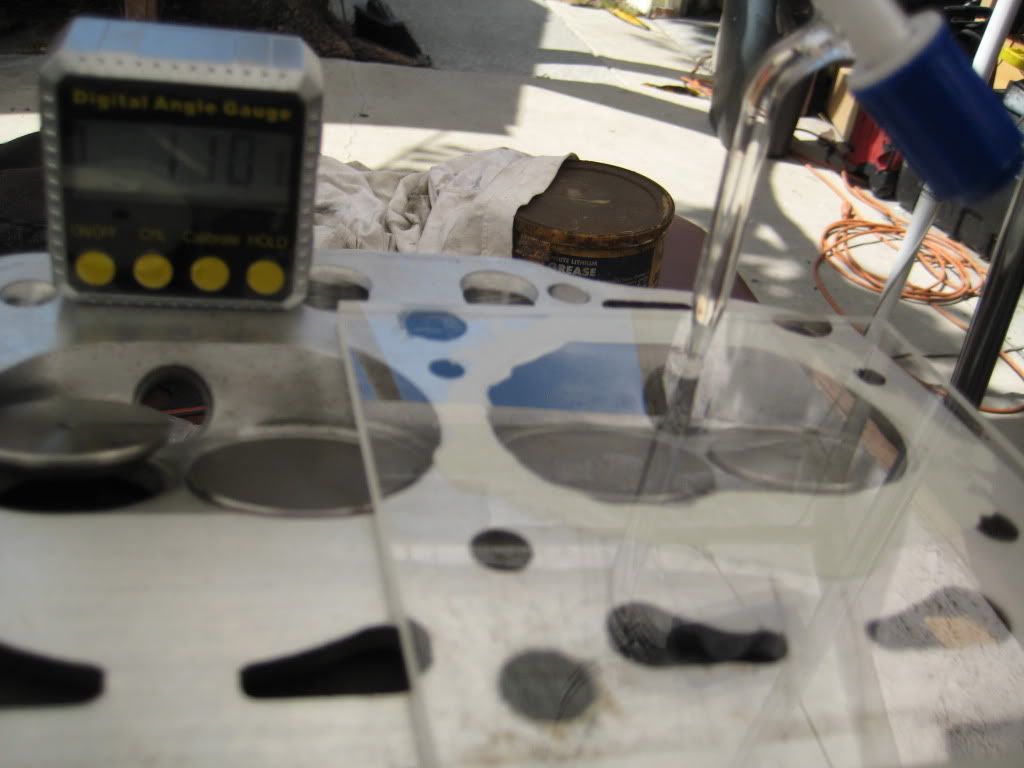

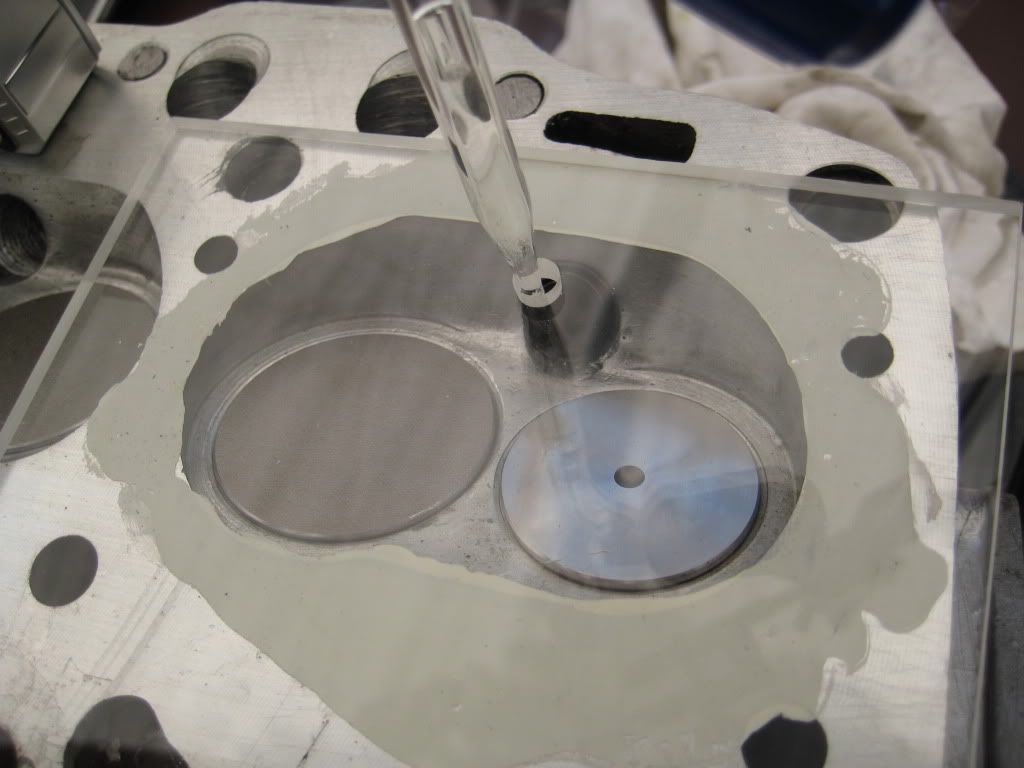

-Complete ported, milled and Big valve head- done

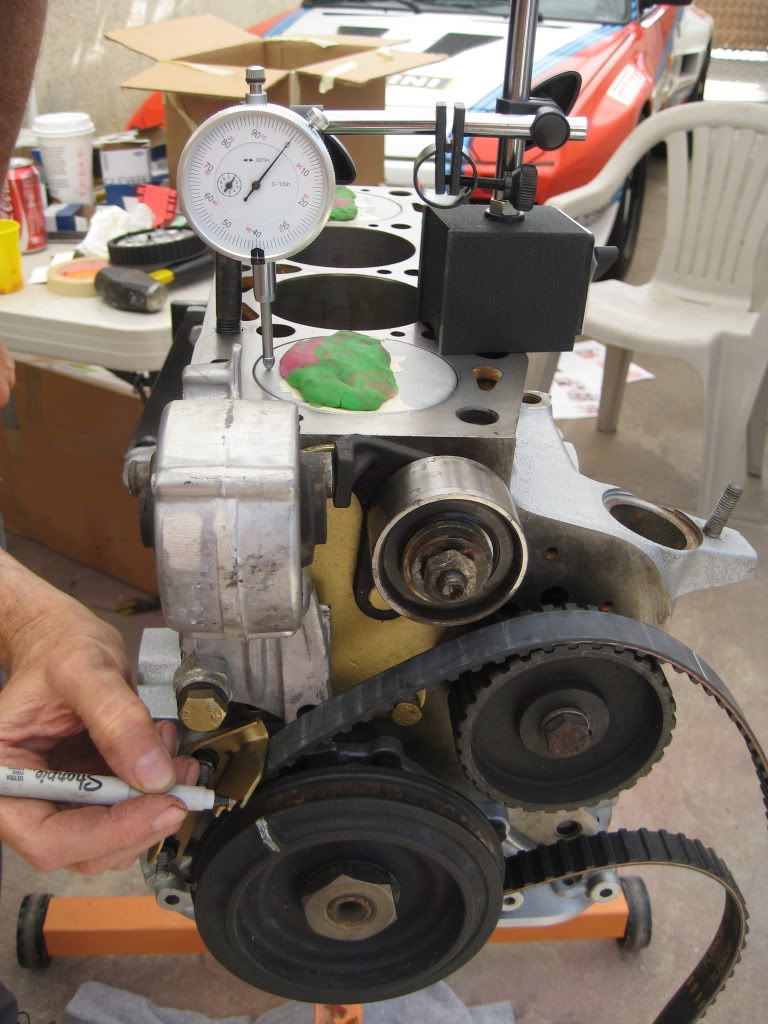

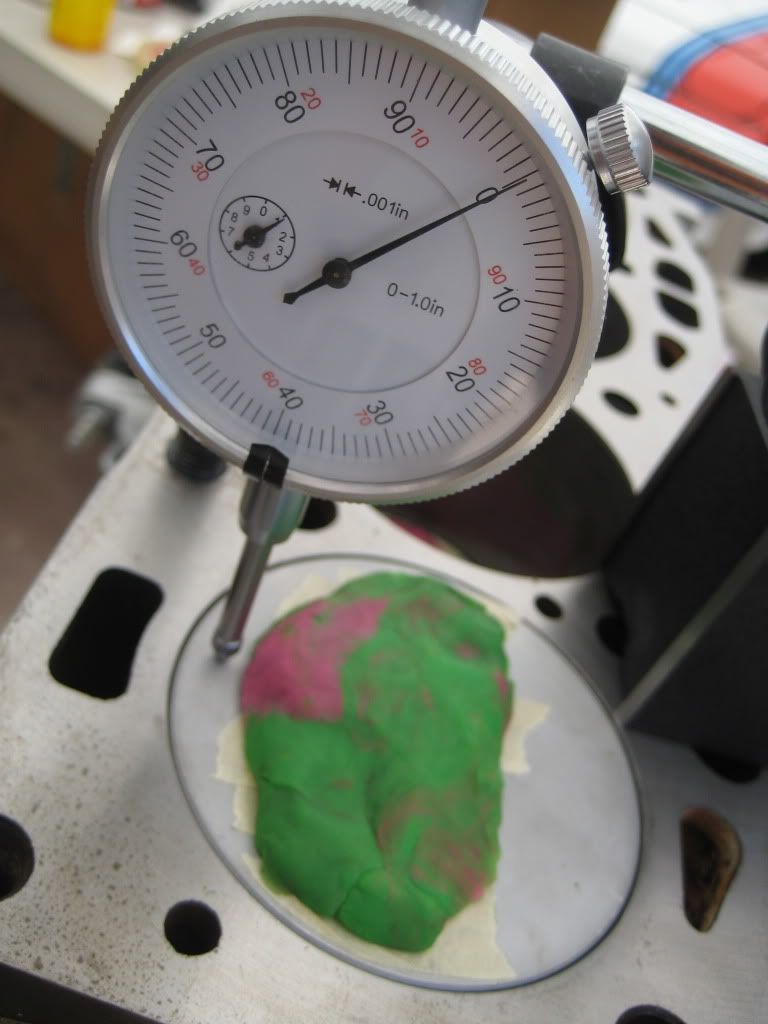

-Camshaft with 11.97mm lift- done

-Main bearing and Crankshaft installation- done (except for one missing main bearing bolt) waiting for some Xweb member to get me one.

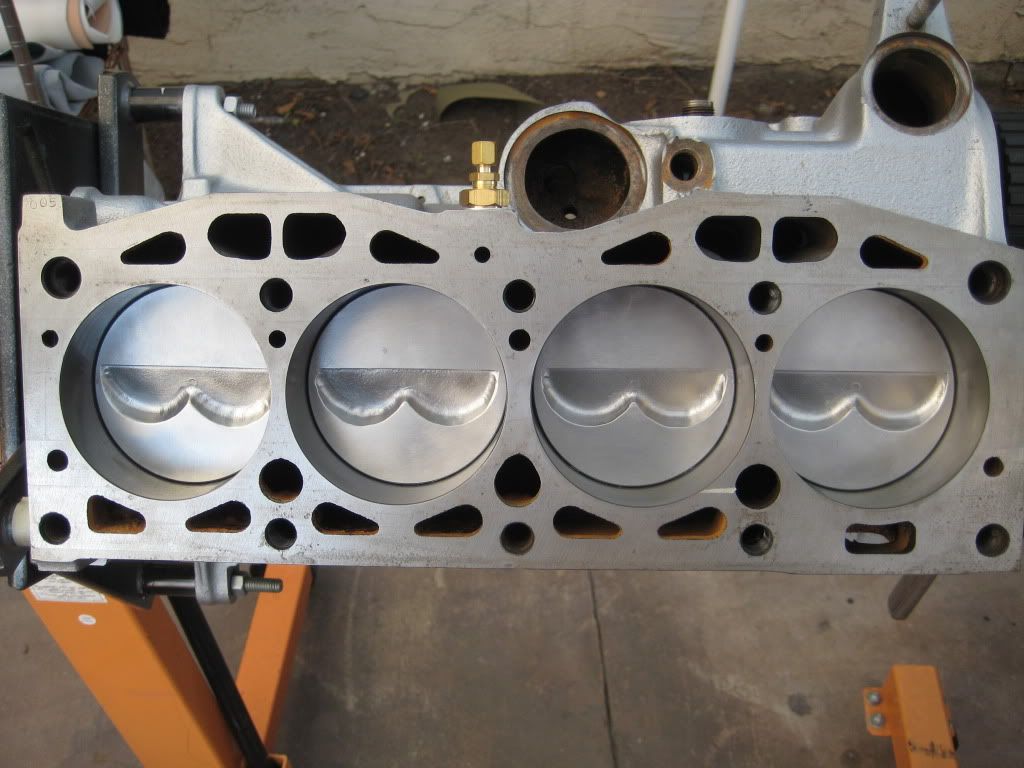

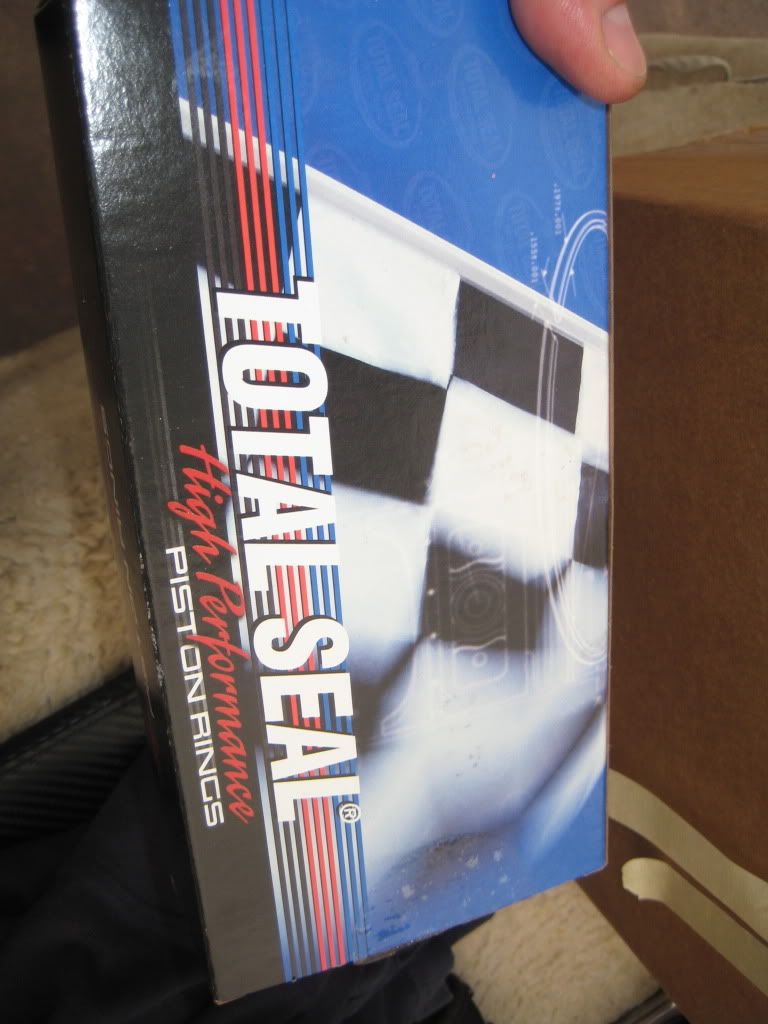

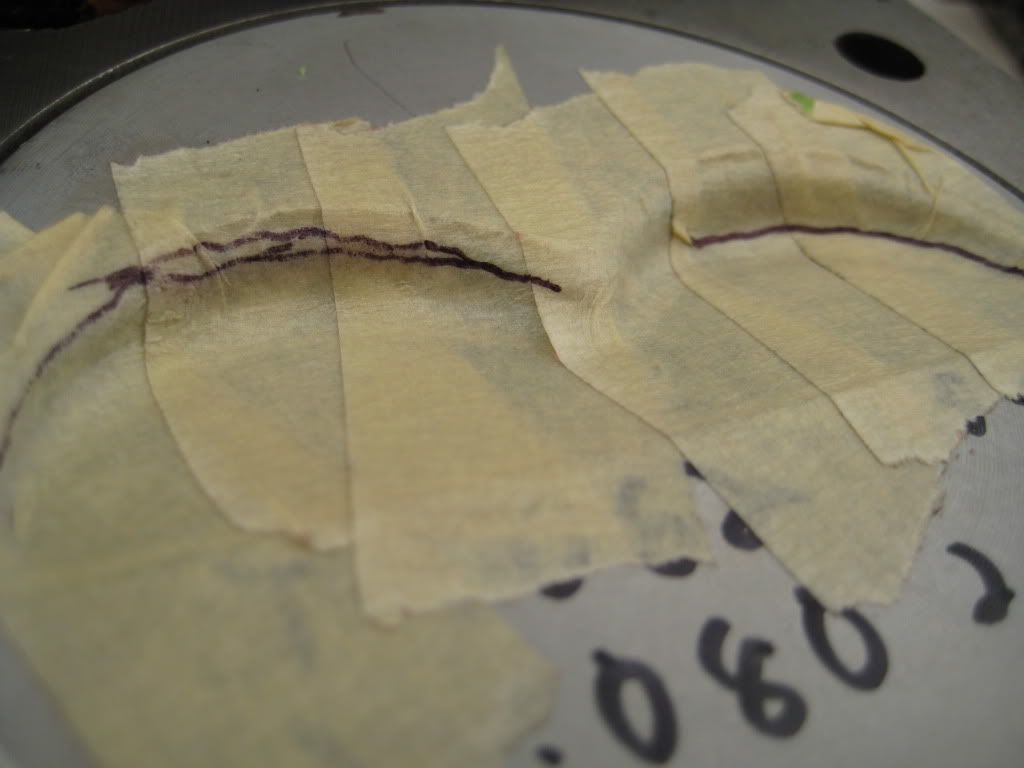

-Original pistons with Total Seal Gapless Top ring set- done

-Grind pistons to make room for big valves- not yet, can accept suggestions

and will report it weekly with pics

-1500 engine with all standard clearances-done

-cleaned and honed-done

-Complete ported, milled and Big valve head- done

-Camshaft with 11.97mm lift- done

-Main bearing and Crankshaft installation- done (except for one missing main bearing bolt) waiting for some Xweb member to get me one.

-Original pistons with Total Seal Gapless Top ring set- done

-Grind pistons to make room for big valves- not yet, can accept suggestions

Last edited: