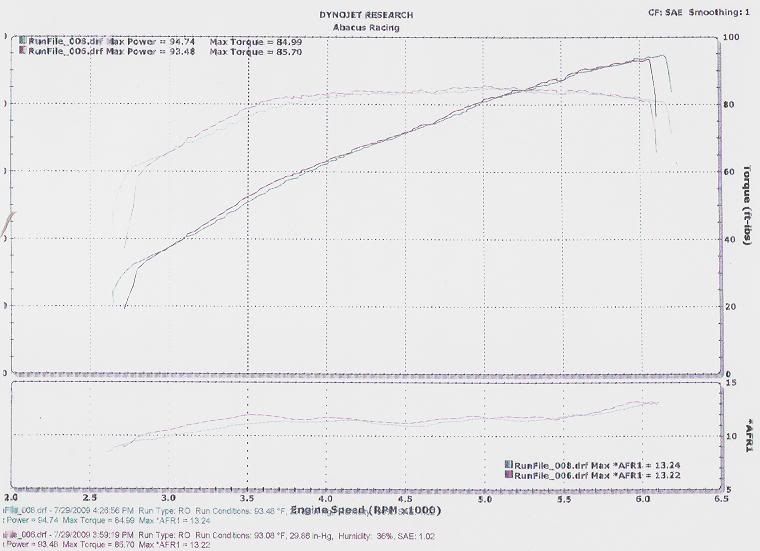

AngleT, I have almost the exact motor you will have if you mill the head, and get more aggresive with the cam. My block has been decked .015" and the head milled flat, approx. .070" from stock. I have the small valve relief (9.2:1) pistons * 87mm bore and a PBS BV head. If you do this, check valve to piston clearance very carfully as it will be close. I also have a PBS B-3 cam and adj. camwheel. Given your at 95 RWHP now, I have no doubt that if you mill your head flat and install a similar cam, you will be at or above 105 RWHP. But the extra compresion will yield a significant gain in tourque, which is what you'll feel when driving.

Will you have to re-jet carbs?.......to see max. potential, yes.

Will you be able to run pump gas?.......with carbs, not likley. I have not calculated my comp. ratio but it is for sure 10.5:1 at least and will detonate under load on 93 octane. I mix 110 octane racing fuel 50/50 with 93 octane premium and it works GREAT. Its's pretty easy, drive till I need gas, dump in 5 gal. of racing fuel, drive to the corner Chevron and top off with premium. I can get 250+ miles on a tank hot footin' around town. I have also run 100 octane low lead av-gas, works equally as well. If you use the deep valve relief pistons, you will be right on the edge of pump gas. Multiple members here have milled heads flat on stock 1500 FI motors and had good results with premium gas, with no block decking.

The most important factor here is piston to head clearance, you want to run that down to .035"-.040". Which will require decking the block also and letting the pistons protrude out the top of the block. This tight squish area around the combustion chamber is what generates tubulence and an efficient burn of the intake charge. If I recall corectly, there is some .090" to .120" of material to remove from the head/block surfaces to get the piston/head clearance right....when you factor in the .050"-.065" head gasket thickness.

A better/easier solution might be the pistons Matt at Midwest/Bayless offers which have a raised compression height to optimise piston/head clearance and yield 11:1 with no milling/decking/cam timing changes.

http://www.midwest-bayless.com/stor...l.aspx?sid=1&sfid=208227&c=193056&i=250926645

I am concidering a bigger cam for my motor as the B-3 is quite streetble with my setup.