Rupunzell

Bernice Loui

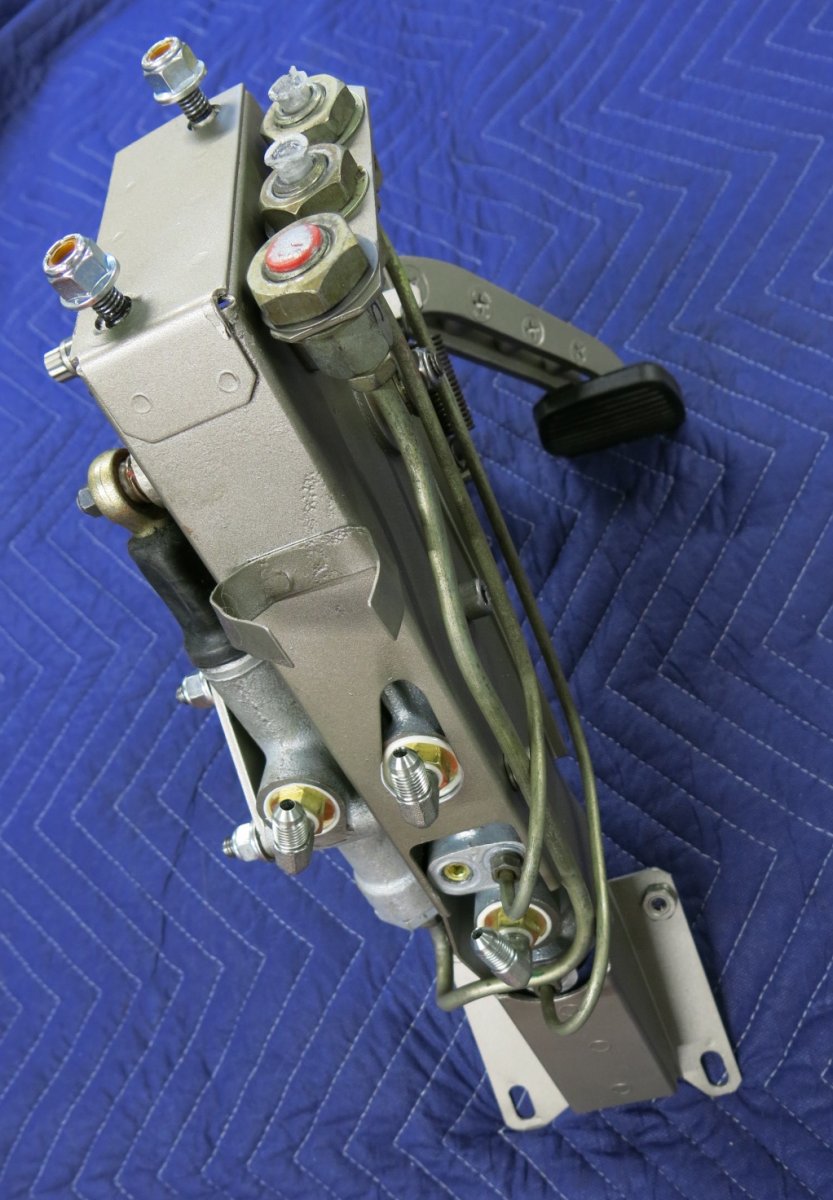

Took more effort to do than the exxe pedal box.

The Lancia pedal box has a different design in various ways even when both master cylinders are essentially the same.

AN-4, JIC 37 degree fittings are used again for the brake fluid inlets. These have been good in many ways.

Making the double stamping brake pedal was not simple, but should help with pedal flex due to the offset angle not found in the exxe brake pedal (it's a better design in some ways). Added a 19mm hex head to the clutch spring plate to ease installation.

Oem Fiat master cylinders were sent out for stainless steel sleeving, rebuilt with new seals and related parts. The current aftermarket replacement master cylinders are hideous inside.. they do work, but.. no thanks. Tubes and tube nuts were good, they got re-used.

LH side.

RH side.

Front.

Top.

Bernice

74' Pedal Box Project

Time to re-do the pedal box for the 74. OEM Fiat cylinders were sent to Karps Brake for sleeving in Stainless steel (304). At this point in time, I flat refuse to use the current afermarket replacement cylinders are they are not equal to Fiat OEM. This is the innards of the clutch master with...

xwebforums.com

The Lancia pedal box has a different design in various ways even when both master cylinders are essentially the same.

AN-4, JIC 37 degree fittings are used again for the brake fluid inlets. These have been good in many ways.

Making the double stamping brake pedal was not simple, but should help with pedal flex due to the offset angle not found in the exxe brake pedal (it's a better design in some ways). Added a 19mm hex head to the clutch spring plate to ease installation.

Oem Fiat master cylinders were sent out for stainless steel sleeving, rebuilt with new seals and related parts. The current aftermarket replacement master cylinders are hideous inside.. they do work, but.. no thanks. Tubes and tube nuts were good, they got re-used.

LH side.

RH side.

Front.

Top.

Bernice