You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Strut braces

- Thread starter ward00

- Start date

Lowtechprime

Retro Grouch

I'm not overly familiar with the tower layout on the Lancias, but in general the most common mistake people make in regards to strut tower braces is they have heim joints at the ends. This defeats nearly all the purpose of the brace. You are attempting to limit the flex of the chassis by triangulation. Imagine if you made a square with joints at each corner, there is nothing to stop it from collapsing into a trapezoid. Look at any factory strut brace, it is mounted with bolts rigidly to the chassis usually with at least 2 bolts per attachment spaced some distance apart to spread the load and resist twisting...

RJ80

True Classic

I recently bought the X1/9 strut brace below to investigate making a set for the Scorpion. Haven't done anything with it yet and have a few more pressing projects ahead of it.

Front Strut Brace $35

$35obo. I have no idea who manufactured this, it did fit well and you can store the top. Shipping additional. Paypal preferred.

xwebforums.com

lanciahf

True Classic

I might be interested in a set if you come up with something.Has anyone installed strut braces in their Lancia? Any idea if these would work?

Thanks

NigelProdrive

True Classic

First thing if not already done is reinforce your rear crossmember.

ward00

True Classic

And pray tell what are the recommended reinforcements, not seeing anything relevant in the Lancia threads for "reinforce"First thing if not already done is reinforce your rear crossmember.

NigelProdrive

True Classic

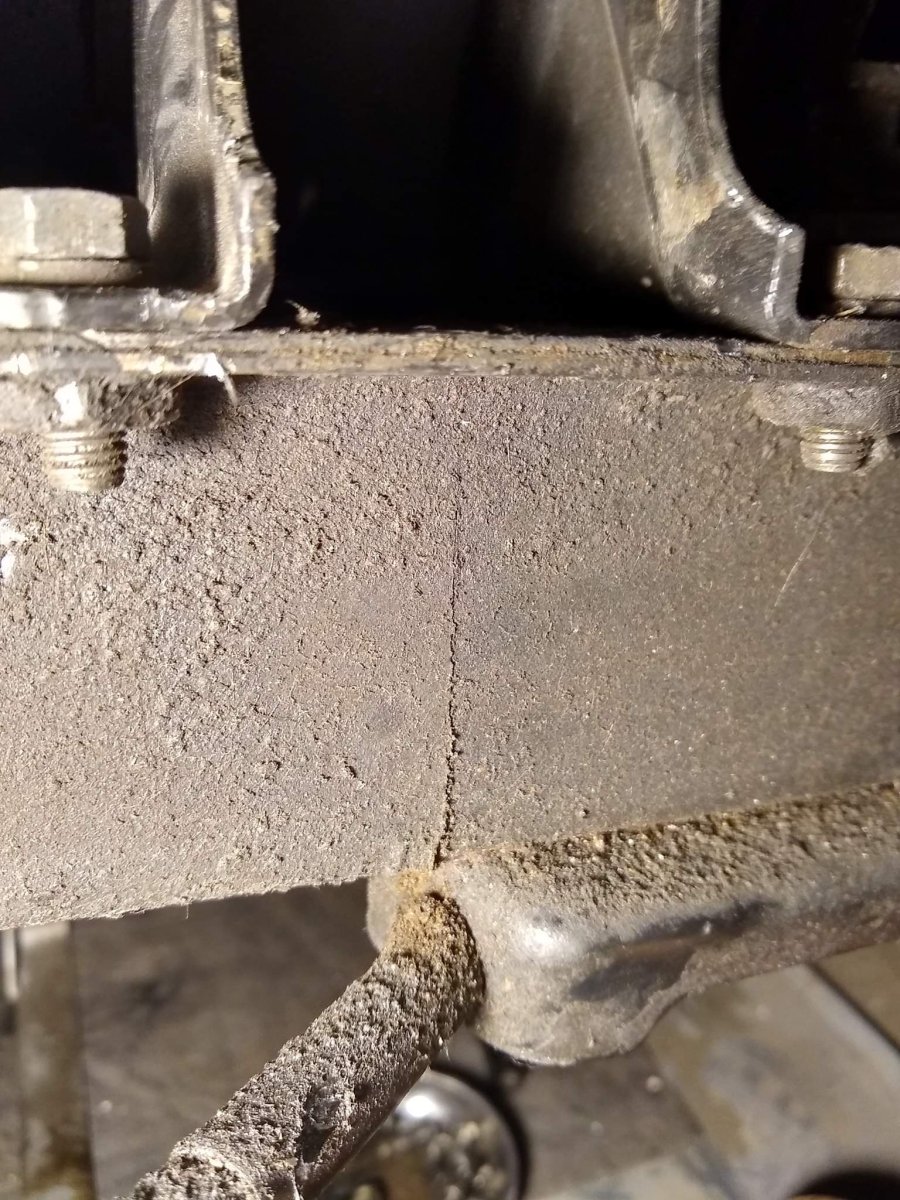

Weld flatbar strips to front and back of rear crossmember. Crossmembers corrode from Inside out and crack. Not my image.

Another.

An idea to prevent moisture inside and add more rigidity it to fill crossmember with expanding foam. Definitely treat inside with anti-corrosion chemical. Use gas tank sealer inside.

Another.

An idea to prevent moisture inside and add more rigidity it to fill crossmember with expanding foam. Definitely treat inside with anti-corrosion chemical. Use gas tank sealer inside.

Last edited:

ward00

True Classic

No, mine is not reinforced. Interesting that the Fiat spider forums have plenty of discussion about how their crossmembers can crack, but for Lancias I haven't been able to find anything on this forum (until now) or the web. Maybe I don't know the magic words to search with.Check the crossmember and you may well see that yours has been reinforced already. Seems most cars have had this done by now, as was the case on mine.

ward00

True Classic

Found this on https://lanciamontecarlo.club/, which gives a little bit more context to the "fix". Probably something I will want to put off until I have to pull the engine. If my member looks like it is intact, would it not make sense to drill a couple of small holes along its length to let any possible water to drain out? Seems to me that filling it with foam would be a moisture trap.

Attachments

kmead

Old enough to know better

You might also look on lancisti.net for some other info around this. A good resource to be a part of.Found this on https://lanciamontecarlo.club/, which gives a little bit more context to the "fix". Probably something I will want to put off until I have to pull the engine. If my member looks like it is intact, would it not make sense to drill a couple of small holes along its length to let any possible water to drain out? Seems to me that filling it with foam would be a moisture trap.

NigelProdrive

True Classic

No, mine is not reinforced. Interesting that the Fiat spider forums have plenty of discussion about how their crossmembers can crack, but for Lancias I haven't been able to find anything on this forum (until now) or the web. Maybe I don't know the magic words to search with.

Many auto forums became ghost towns after Facebook. Wasn't going to mention lancisti.net here unless mods approved but now that Karl has, its Lancia oriented than looking on a Fiat forum. But there are Facebook groups dedicated to Montecarlo and Montecarlo restoration and that is where I grabbed some of the photos of crossmembers I shared above.

Monte Hospital sold a upgraded crossmember but are out of stock or no longer producing.

Some people claim it cracks due to stress from engine rotating with torque and the solution is to add a upper engine mount to the rear shelf. And that reinforcing the top of crossmember is better due to that stress.