Clatter

True Classic

A couple small things knocked out.

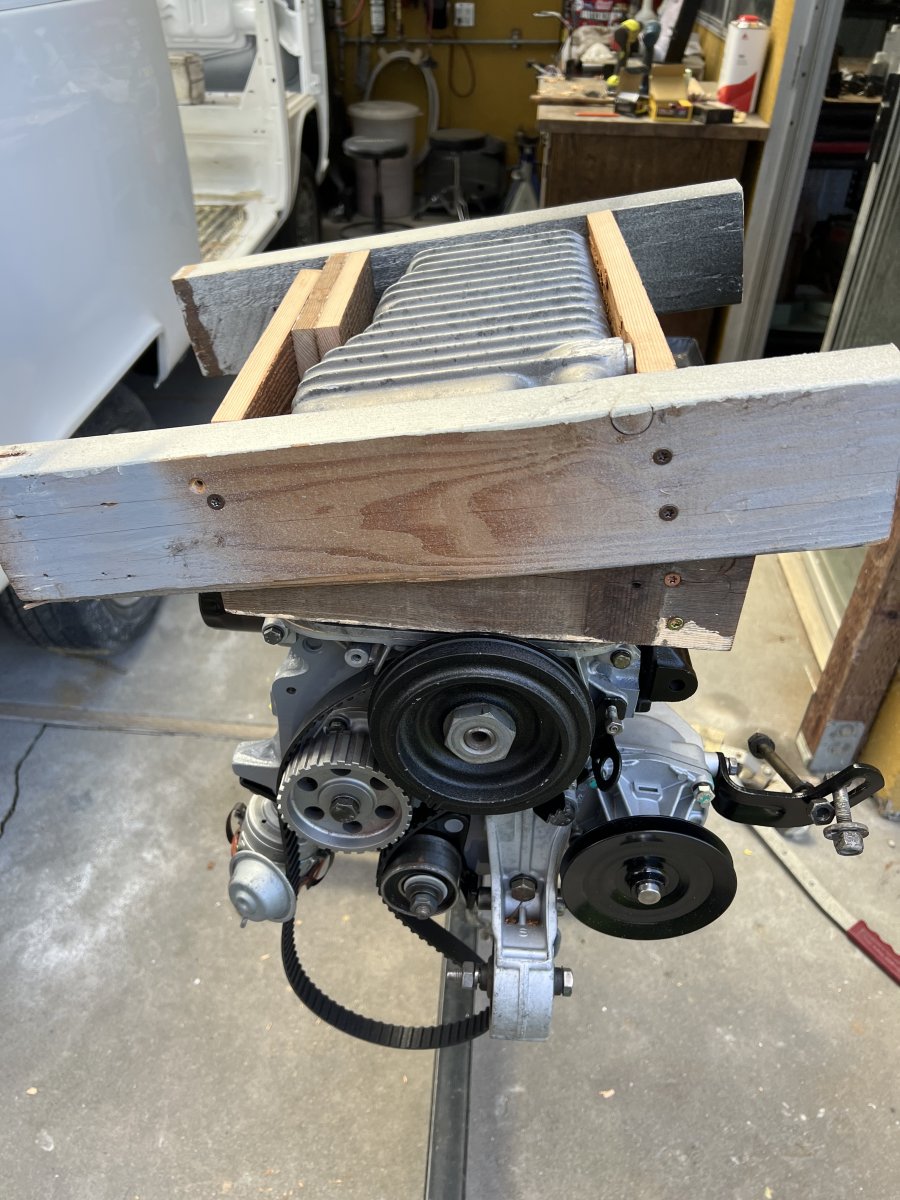

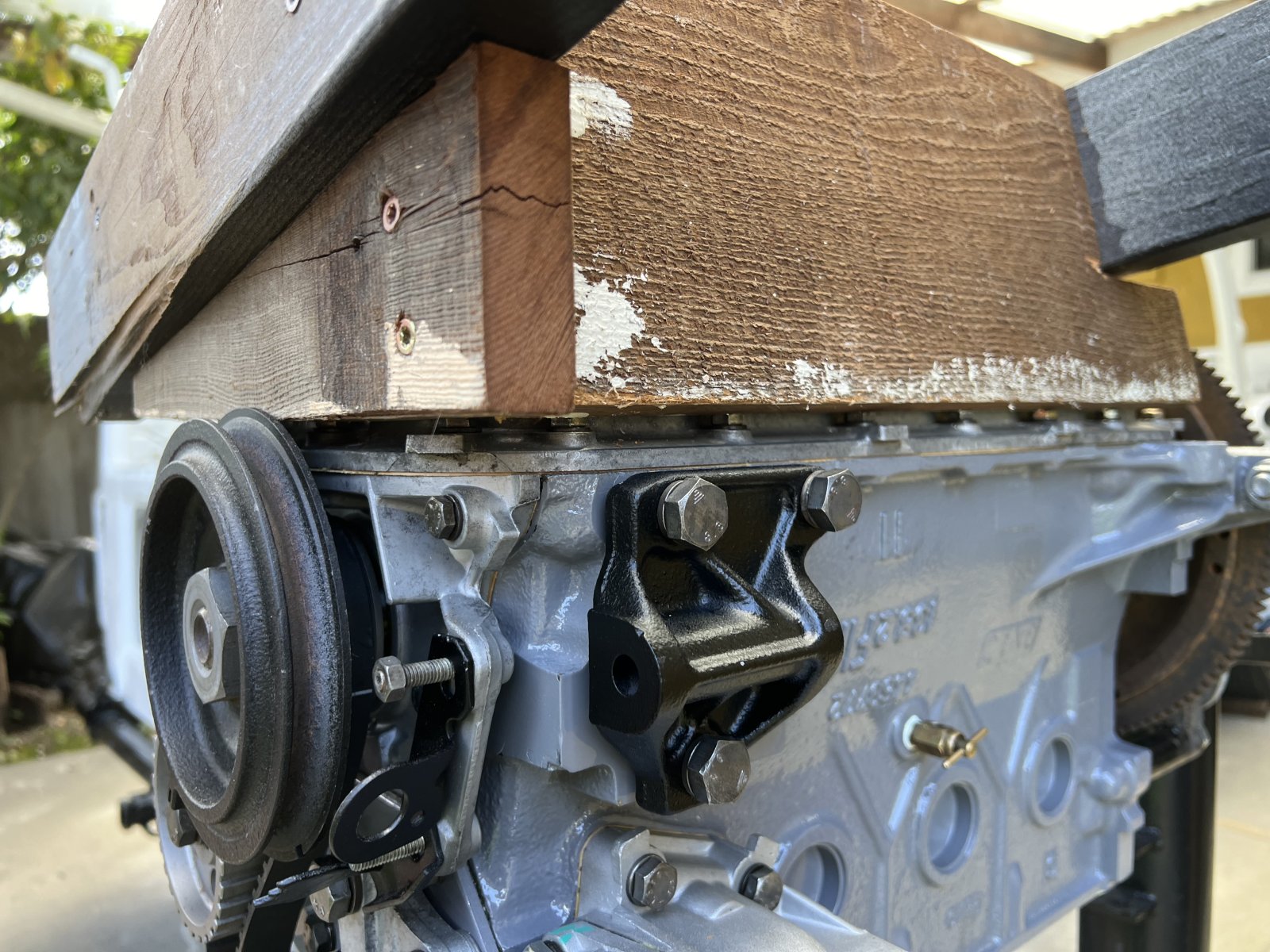

Stabbing this new motor needs to go differently than the pull did.

Can't be just dragging it...

Ever hear the one about the dog with no legs?

Figured a little wooden box, open in the bottom, that would pick up the pan bolts:

If nothing else, it keeps the motor upright for storage.

The head might be a while. I need my stand back.

Same with the transaxle...

Right as we were buttoning up,

Close inspection revealed the little band brakes inside 5th had burrs on the ends.

Right away a NOS Italian pair showed up on ebay.it so i went for it.

Several weeks later, only one shows.

They say they're sending me the other,

Trans is getting set aside until then.

Plenty of other things to do,

Like cleaning the drain plug.

Reminds me where we came from.

How did those rats manage to get THIS dirty!?!?

Went out to Osuna's Auto Electric in Watsonville, CA.

They rebuilt my alternator for $200.

New bearings and brushes, turned commutator, etc.

I'm feeling more trusting at this point.

Support your local rebuilder if you got one!

Since I'm now waiting on hose to finish the intake,

That stuff got bagged up and put away as well.

Somehow, a clean workbench eases my soul and makes me hopeful.

Parts well-packed can all be dragged out and taken to the finish line once the stragglers trickle in.

Unfinished business right front/center in the way gives me the hump.

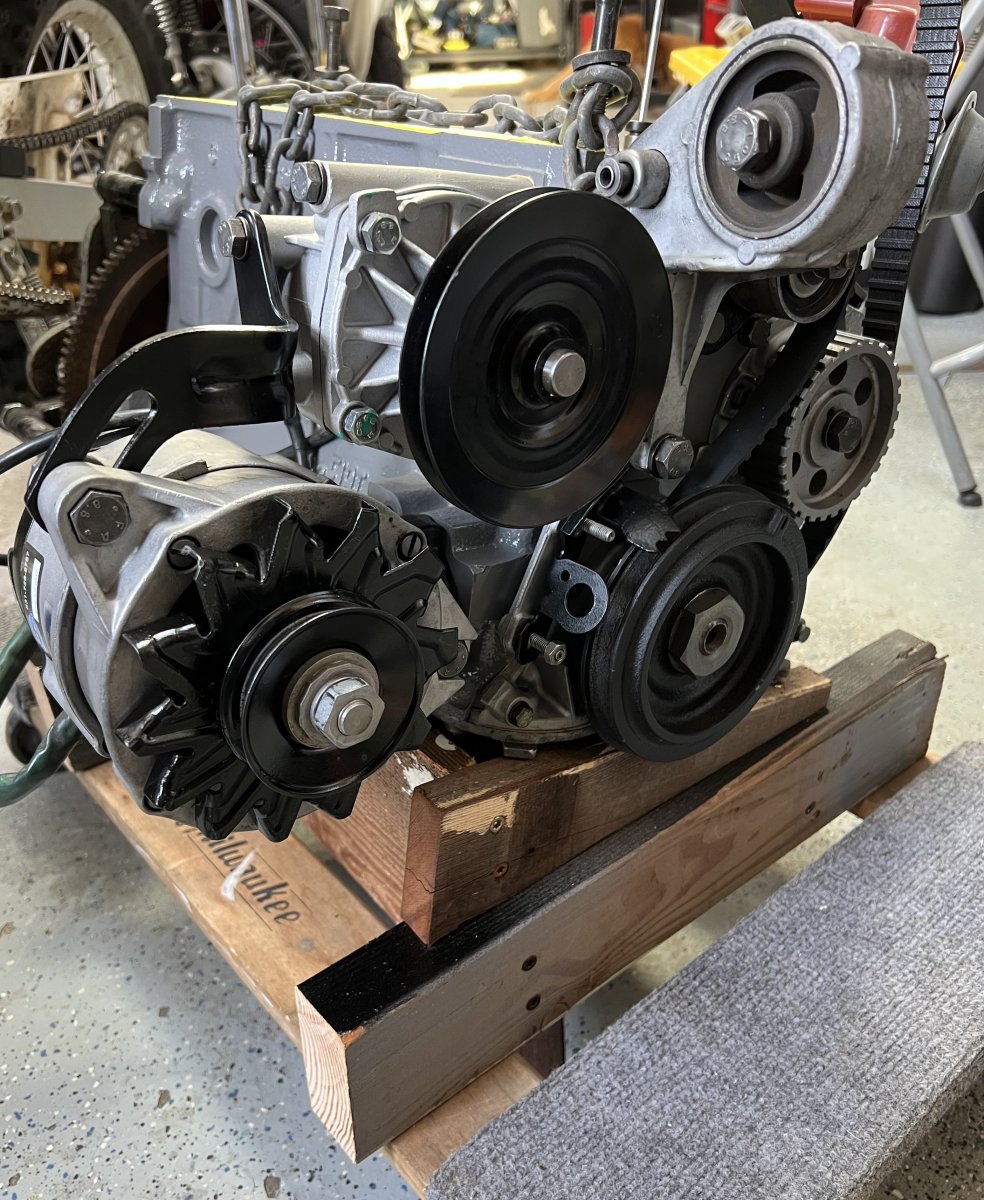

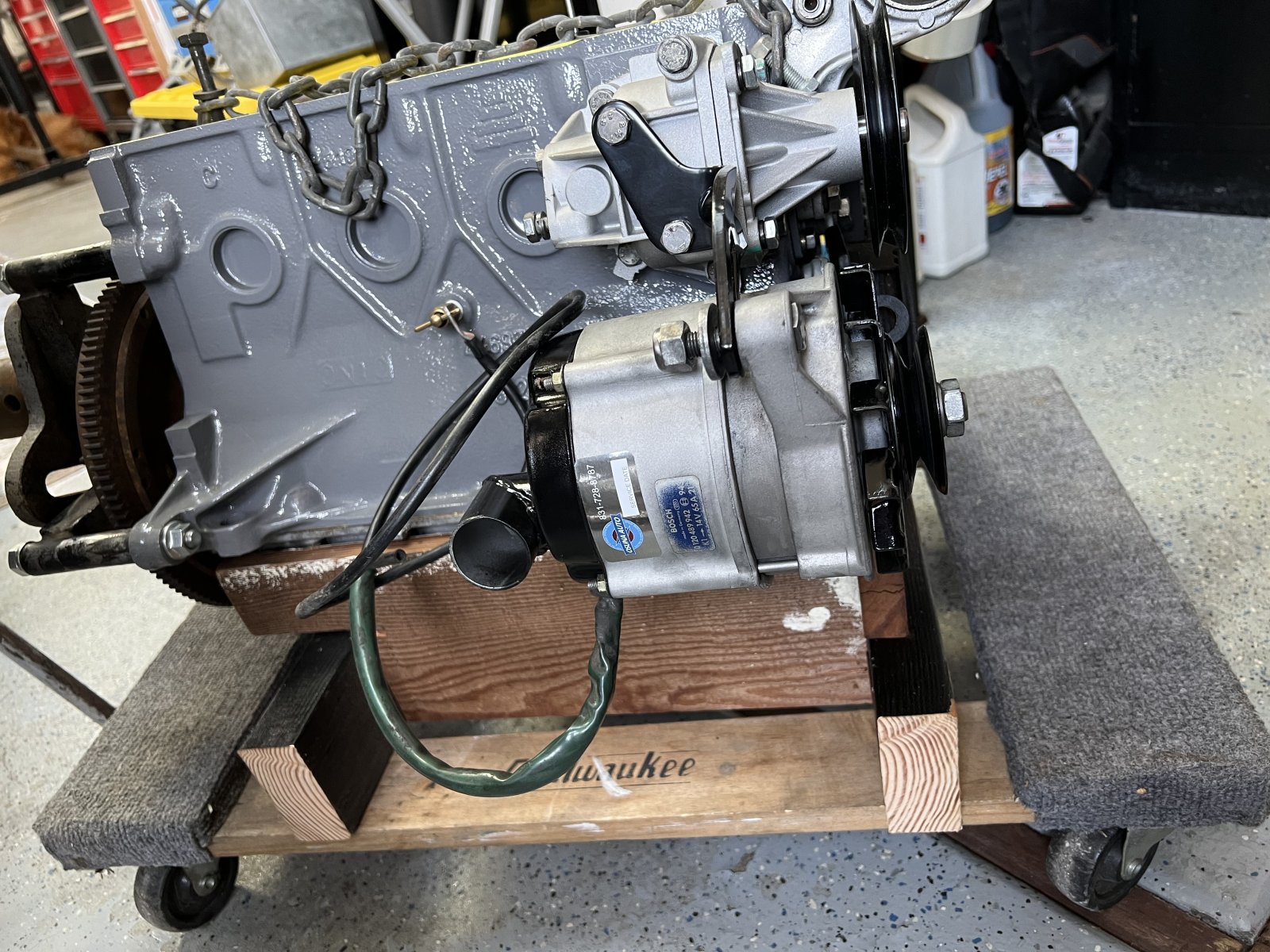

Hoisted the motor onto my new stand and a furniture dolly and rolled it to a back corner.

Cleaned up alternator mounting stuff and put it in place.

Vroom!

Vroom! Vroom!!

Now we can move onto hydraulics, compartment.. wiring... dash... heater....

Without all this junk stuck waiting clogging up my work area (and brain).

Part of the process, right?

Stabbing this new motor needs to go differently than the pull did.

Can't be just dragging it...

Ever hear the one about the dog with no legs?

Figured a little wooden box, open in the bottom, that would pick up the pan bolts:

If nothing else, it keeps the motor upright for storage.

The head might be a while. I need my stand back.

Same with the transaxle...

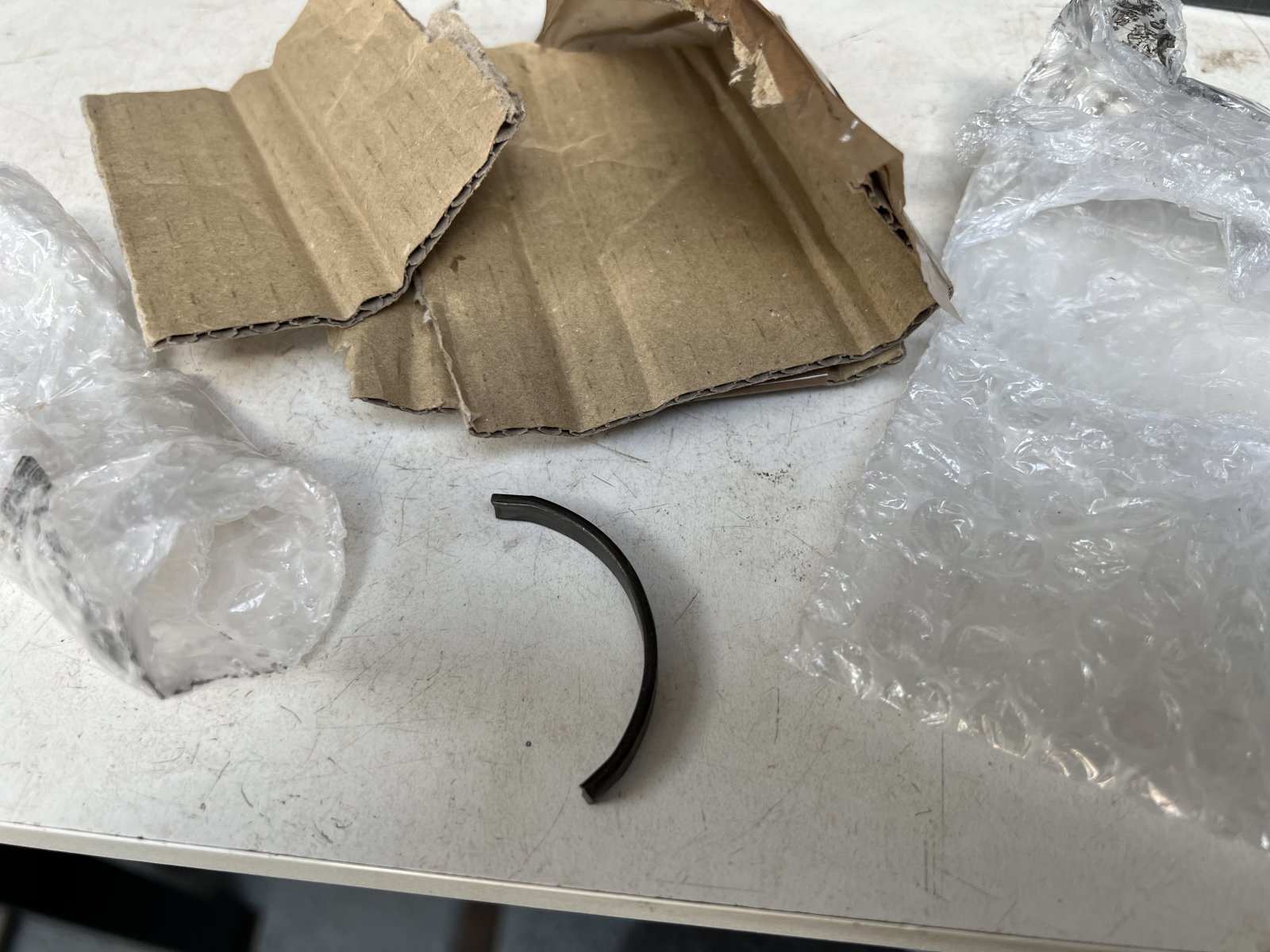

Right as we were buttoning up,

Close inspection revealed the little band brakes inside 5th had burrs on the ends.

Right away a NOS Italian pair showed up on ebay.it so i went for it.

Several weeks later, only one shows.

They say they're sending me the other,

Trans is getting set aside until then.

Plenty of other things to do,

Like cleaning the drain plug.

Reminds me where we came from.

How did those rats manage to get THIS dirty!?!?

Went out to Osuna's Auto Electric in Watsonville, CA.

They rebuilt my alternator for $200.

New bearings and brushes, turned commutator, etc.

I'm feeling more trusting at this point.

Support your local rebuilder if you got one!

Since I'm now waiting on hose to finish the intake,

That stuff got bagged up and put away as well.

Somehow, a clean workbench eases my soul and makes me hopeful.

Parts well-packed can all be dragged out and taken to the finish line once the stragglers trickle in.

Unfinished business right front/center in the way gives me the hump.

Hoisted the motor onto my new stand and a furniture dolly and rolled it to a back corner.

Cleaned up alternator mounting stuff and put it in place.

Vroom!

Vroom! Vroom!!

Now we can move onto hydraulics, compartment.. wiring... dash... heater....

Without all this junk stuck waiting clogging up my work area (and brain).

Part of the process, right?

Last edited: