Well I have a couple of pictures.

The trouble is, mine is a ‘79s and ‘79s are a slightly different beast than later “late model” Xs. At least this is certainly true of the alternater-waterpump-crank pulley belt arrangements. On ‘79s with AC, the alternator is piggy-backed on the compressor rather than mounted in stand-alone brackets, the compressor pulley was driven directly from the crank pulley, and the alternator and water pump were driven from the compressor pulley. Totally different from other AC models.

Mine was converted a few weeks out of the dealer’s lot in 1979. The bracketry was poorly done, and although I have tried to clean it up over the years, frankly I have never succeeded in getting it the way I would like to see it. (I think this may be where my psychosis originates about not liking it when people change things from stock.) Poor design or not, I guess it must be o.k. because it has worked for 30 years with no problems.

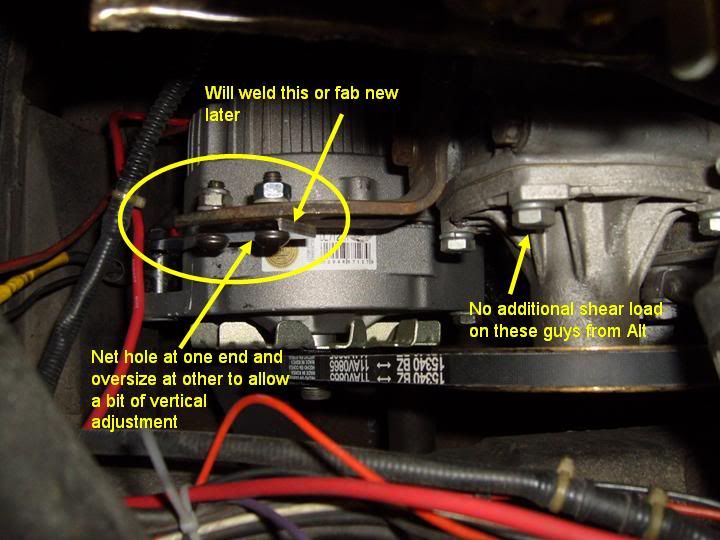

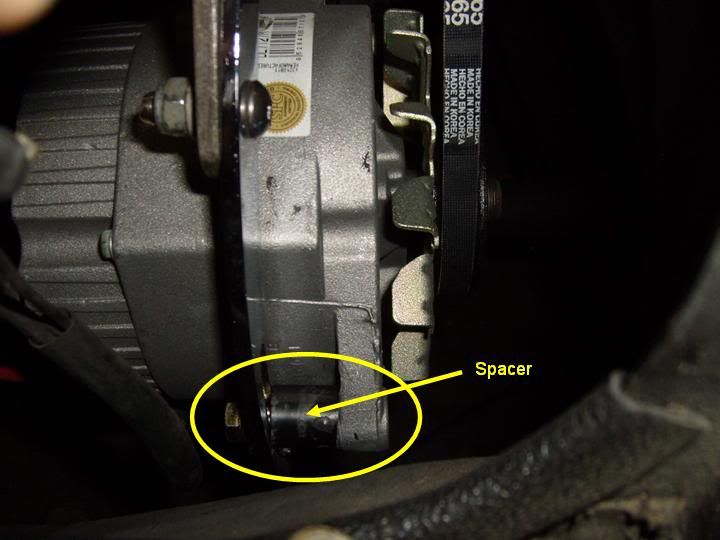

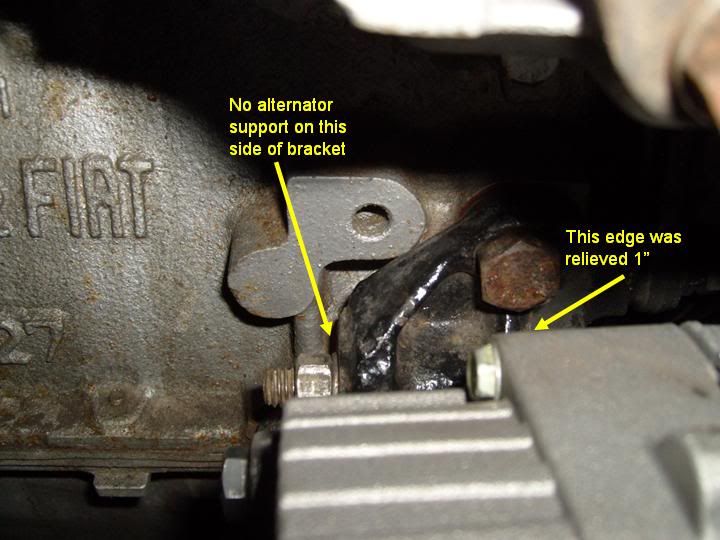

The key in installing one is to get the Delco positioned precisely in the “sweet spot” between the carb/FI superstructure, the intake manifold, the rear trunk wall, and the upper rear engine compartment frame structure. Once that is done, you have about a half inch of adjustment, optimistically speaking, the rearward motion being constrained by the rear engine compartment frame structure and trunk wall, and the forward motion being limited by the intake manifold.

It seems like a lot of work, but it pays off. These alternators seem very happy with life in an X’s engine compartment. I think I have replaced the alternator maybe twice in 30 years.

AC-Delco Alternator Pictures: