I followed Ulix' instructions on replacing the bearings but thought I would take pictures to illustrate. These are for a 1987.

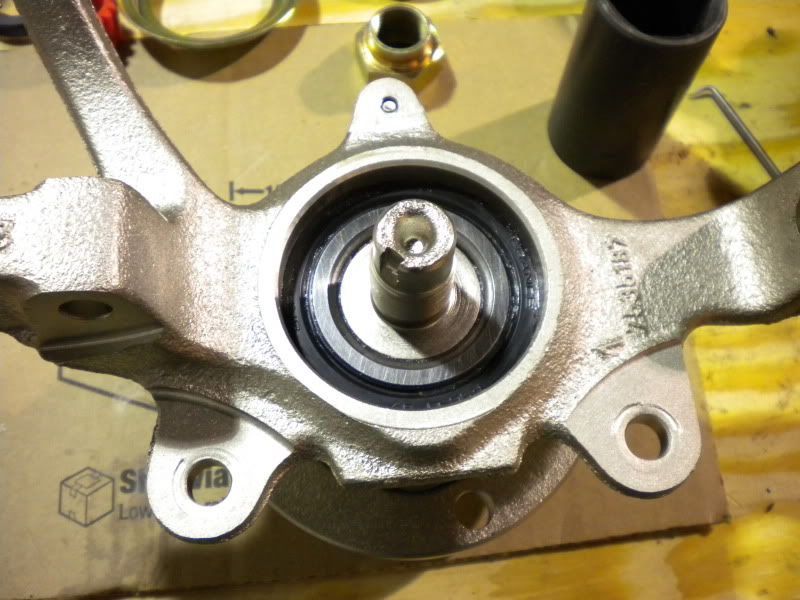

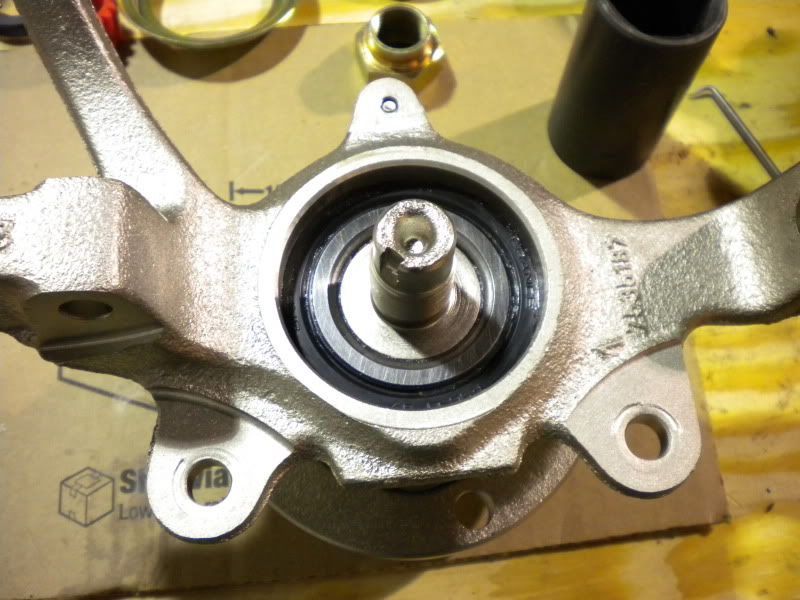

I loved the way the E-Type suspension looks so I nickel plated the uprights:

I bought a full kit for the bearings including the seals, nuts, snap rings and covers. I press fit the bearing into the knuckle using the press - be sure to push it in straight, that was the trickiest part of setting it up on the press. After the bearing was in place I secured it with the snap ring (it's a whole lot easier to put on!)

I then setup the hub to press into the bearing I pushed on the (gold) metal cover and attached the rubber seal to the hub making sure that the "V" side of the rubber seal faces the bearing.:

Back to the press, making sure to support the inner race of the bearing while pressing in the hub (I used a large socket).

I then fit the other gold cap, followed by the washer and rubber seal (again "V" towards the bearing) and fit the hub nut.

The rear bearings are pretty musch the same process except instead of the snap ring you have the screw on retainer staked in place:

And the rubber seal fits on the hub the same way:

All done:

Cheers,

Glen

I loved the way the E-Type suspension looks so I nickel plated the uprights:

I bought a full kit for the bearings including the seals, nuts, snap rings and covers. I press fit the bearing into the knuckle using the press - be sure to push it in straight, that was the trickiest part of setting it up on the press. After the bearing was in place I secured it with the snap ring (it's a whole lot easier to put on!)

I then setup the hub to press into the bearing I pushed on the (gold) metal cover and attached the rubber seal to the hub making sure that the "V" side of the rubber seal faces the bearing.:

Back to the press, making sure to support the inner race of the bearing while pressing in the hub (I used a large socket).

I then fit the other gold cap, followed by the washer and rubber seal (again "V" towards the bearing) and fit the hub nut.

The rear bearings are pretty musch the same process except instead of the snap ring you have the screw on retainer staked in place:

And the rubber seal fits on the hub the same way:

All done:

Cheers,

Glen