TonyK

True Classic

I am working on Bob Martin's car this week with a few items that have surfaced or have been haunting us. First off he has a transmission leak on the left side half shaft adapter at the transmission. As discussed in another thread the parts so far seem to be the same between the Abarth manual transmission and the X1/9 transmission. Bob did order a seal from Fiat in Louisville Kentucky the seal was $37 Just to let you know they can be purchased for alot less than that at MidWest Bayless. We changed the shaft adapter and seal as it showed pitting at the seal rub location. Time will tell if we are successful.

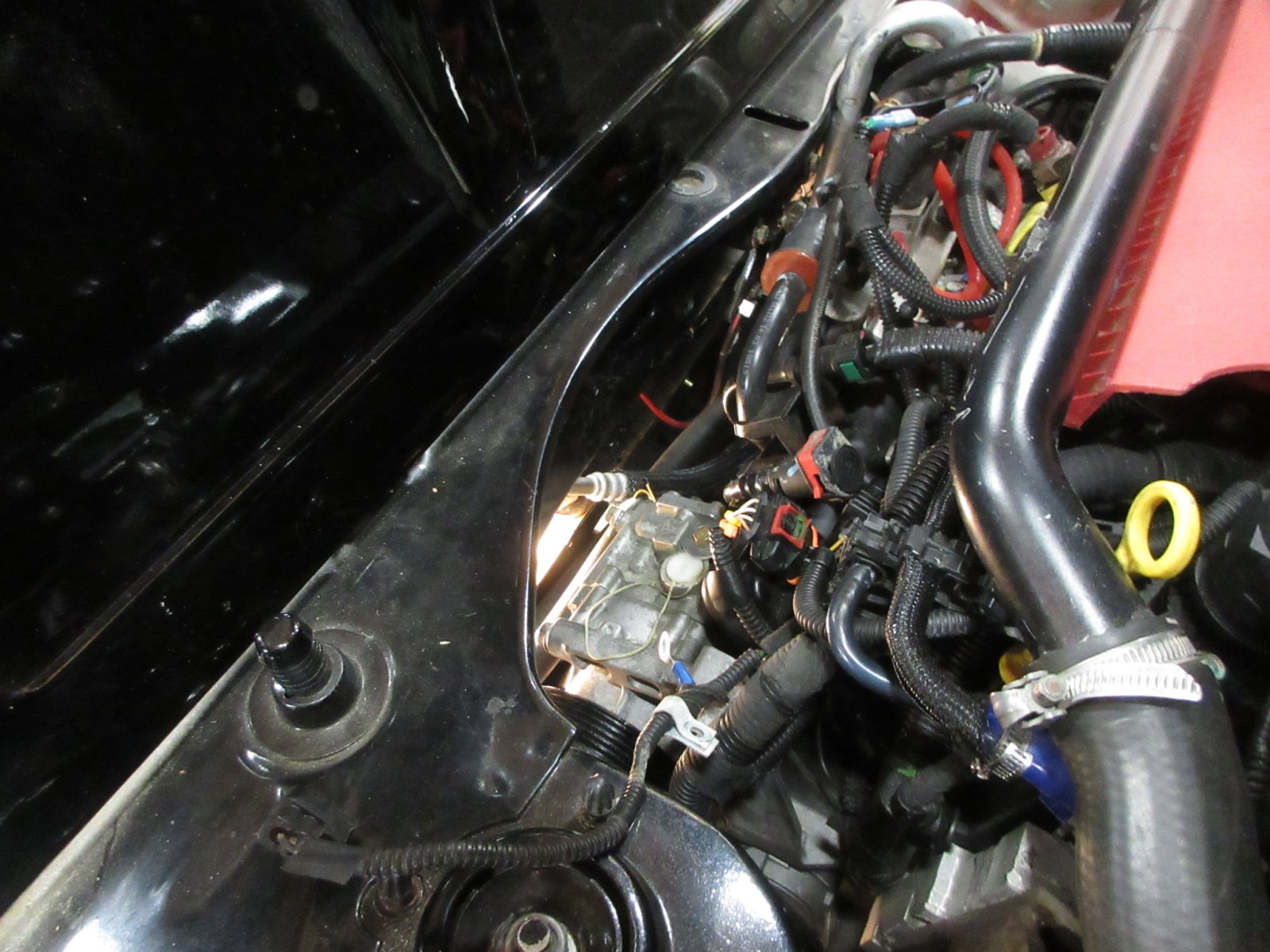

The other problem that has been haunting me and Bob is that we have not been able to get the Air Conditioning working on his car. The car did not come with A/C but over the years I had purchased AC parts for the car and when the build was happening at my house the AC system was installed. The 86 body was wired for both AC and Non AC use so the wiring changes were fairly simple. Bob, Jim Decker and I made an attempt to get the AC working before FFO in Texas, but were not successful. In the fall of 2023 again we opened the system and flushed it, it was contaminated. When do my builds once all of the welding is completed the engine bay is sand blasted. The down side of this is that there is a lot of sand everywhere and I suspect that when one of the lines was being pulled through the body sand entered the lines. Flushing in the fall of 2023 presented grit in the flush catch can and although we thought the system was clear we were not able to build any real head pressure. I found two used AC compressors and today we changed one out and I pulled the head from the removed AC compressor. Sand. The valve plates were stuck open with grit. We changed out the compressor, this requires displacing the module box, tomorrow we will flush the system again and install a filter screen ahead of the compressor on the suction line.

A few pictures.

TonyK at Bob Martin's in Radcliff Kentucky.

The other problem that has been haunting me and Bob is that we have not been able to get the Air Conditioning working on his car. The car did not come with A/C but over the years I had purchased AC parts for the car and when the build was happening at my house the AC system was installed. The 86 body was wired for both AC and Non AC use so the wiring changes were fairly simple. Bob, Jim Decker and I made an attempt to get the AC working before FFO in Texas, but were not successful. In the fall of 2023 again we opened the system and flushed it, it was contaminated. When do my builds once all of the welding is completed the engine bay is sand blasted. The down side of this is that there is a lot of sand everywhere and I suspect that when one of the lines was being pulled through the body sand entered the lines. Flushing in the fall of 2023 presented grit in the flush catch can and although we thought the system was clear we were not able to build any real head pressure. I found two used AC compressors and today we changed one out and I pulled the head from the removed AC compressor. Sand. The valve plates were stuck open with grit. We changed out the compressor, this requires displacing the module box, tomorrow we will flush the system again and install a filter screen ahead of the compressor on the suction line.

A few pictures.

TonyK at Bob Martin's in Radcliff Kentucky.