Rob1400T

Daily Driver

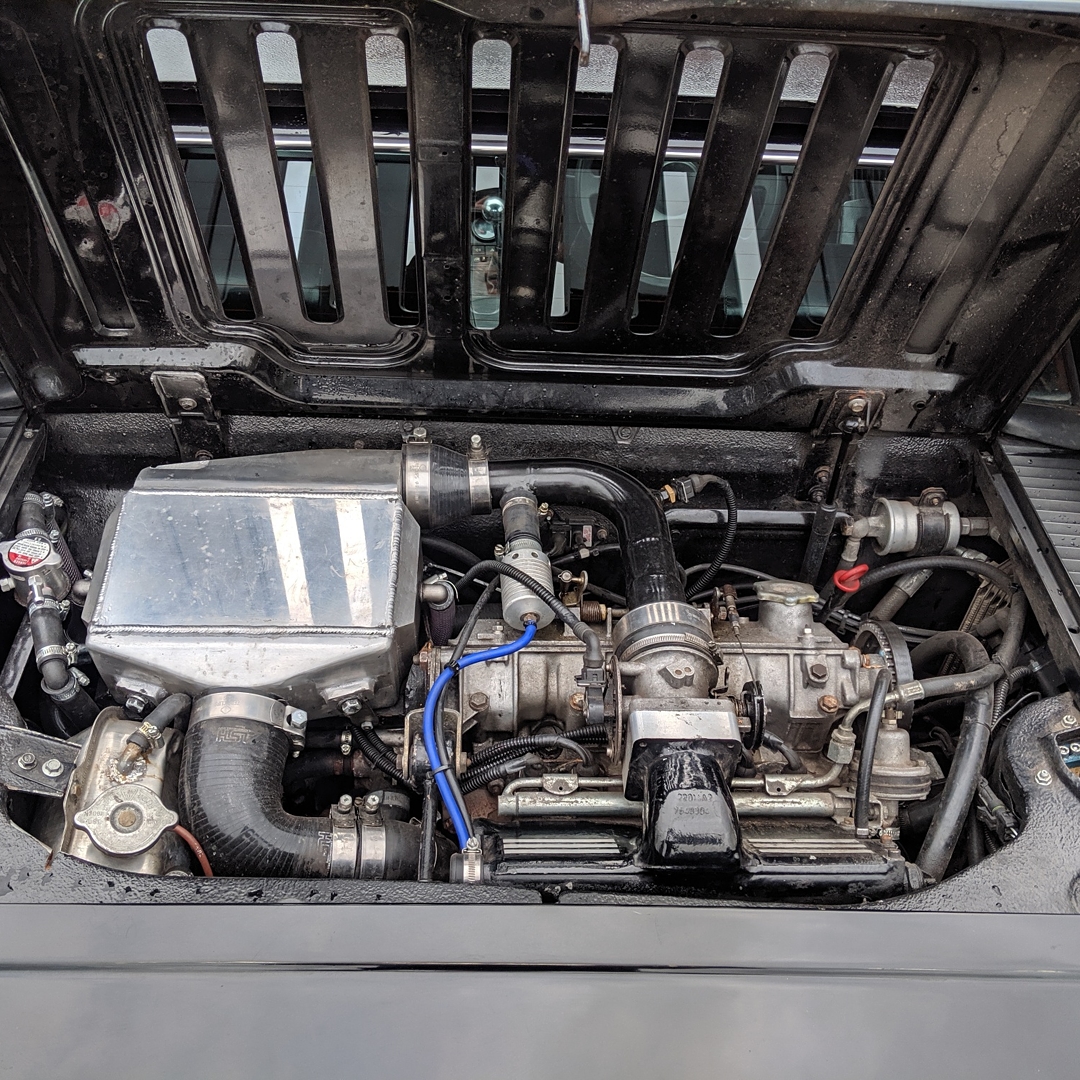

I'm rather late to this thread but I've had a scan through and have found a lot of the conversation familiar. Mine is a road car with the engine from a 1.4 Uno turbo. I still retain both boots as I wanted to keep it as 'standard looking' as possible. If I can help with anything, just let me know. Some of you will know me on my Instagram @retrokid1983

Last edited: