bikesandcars

True Classic

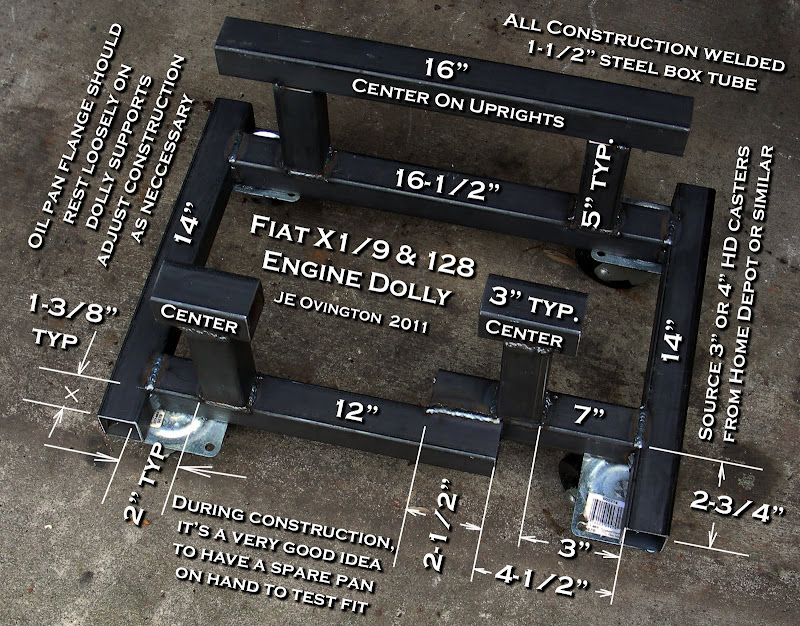

Has anyone here ever built an engine cradle? I obviously can't find ones for sale, so I need to make one.

any pictures?

any pictures?

I can't play with my new welder with your plan Matt!!

I got a small HF mover's dolly to use for now. Says it will move up to 1000lbs, so it should work OK and I was planning to use a strap to keep the engine on board.

That does help.

Would you go one step further and give us dimensions to save us from reinventing the wheel, er, that is the dolly? Is that 2" square tubing?