More details:

Sorry guys, I should have known to post more details from the start. Here goes.

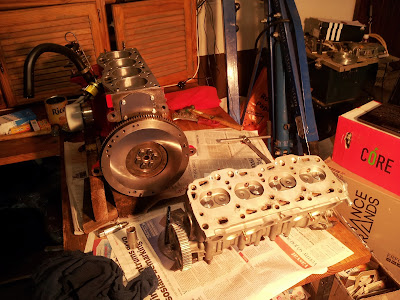

Short version:

--> 1500 X1/9 block

--> 1500 X1/9 crank (as far as I can tell)

--> 86mm bore

--> Nissan SR20de pistons

--> Uno Turbo (MKII) conrods

--> Uno Pacer (1400) head

--> Uno Pacer camshaft (standard cam)

--> Garrett T25 BB Turbo (off a Nissan 200SX) - 0.6bar

--> Uno Turbo Intake Manifold

--> Custom Intercooler

--> Custom exhaust manifold

--> Custom freeflow exhaust

--> Spitronics engine management

Long Version: :woot:

I bought Brutus a few months ago as a fun little runabout/project, instead of buying something boring like a VW Polo. He was fitted with a Uno Turbo head and camshaft as well as some turbo off a Volvo. PO promised me reliability and economy, I suspected otherwise but I was in love, so I bought him anyway. :nuts:

Problems started immediately, smoked like hell until the turbo got warmed up. Used water and overheated intermittently. I replaced the turbo (with the T25) and the smoking stopped. Happiness, for a bit :sigh: The overheating got worse and I suspected a headgasket.

Compression test revealed a leaking headgasket. I took the head off and found worse. Head cracked in at least 5 places (into waterjacket and between exhaust and intake valves) and a badly worn camshaft (all lobes worn and 2 exhaust lobes basically MIA).

Reaction-->

Sourced a head that would work (Uno Pacer 1400) and a matching camshaft that apparently works well with a turbo (also off a Uno Pacer). Managed to figure out what pistons were used in the engine by the PO (Nissan SR20de) and concluded that he wanted to use them to drop the compression ratio for the turbo (he was boosting 1bar when I bought the car and had gone as high as 1.6bar). I sourced some new oversize pistons (SR20de, 86mm) and had the blocked bored to match.

Crank also had to be reground undersize and new bearings were sourced. I did some work on the head (light polishing and porting) while I waited for parts. Sorted out the cooling system to work with the new head (thermostat housing works differently from X1/9) and plumbed in some watercooling for the turbo. I also did some other bits and pieces like find a flatter oil filter housing that, when mated to the oil cooler manifold, can actually be replaced without pulling out the motor. :woot:

Right now the bottom end is assembled and the head is assembled with new valves and torqued down. Everything feels and looks good. Finding a cam cover locally is all but impossible so I don't think that's really an option. Buying a dial gauge appeals to the engineer in me but I would really like to get Brutus back on the road asap! I guess jvandyke's signature applies

Thanks for the replies so far!