robsad

True Classic

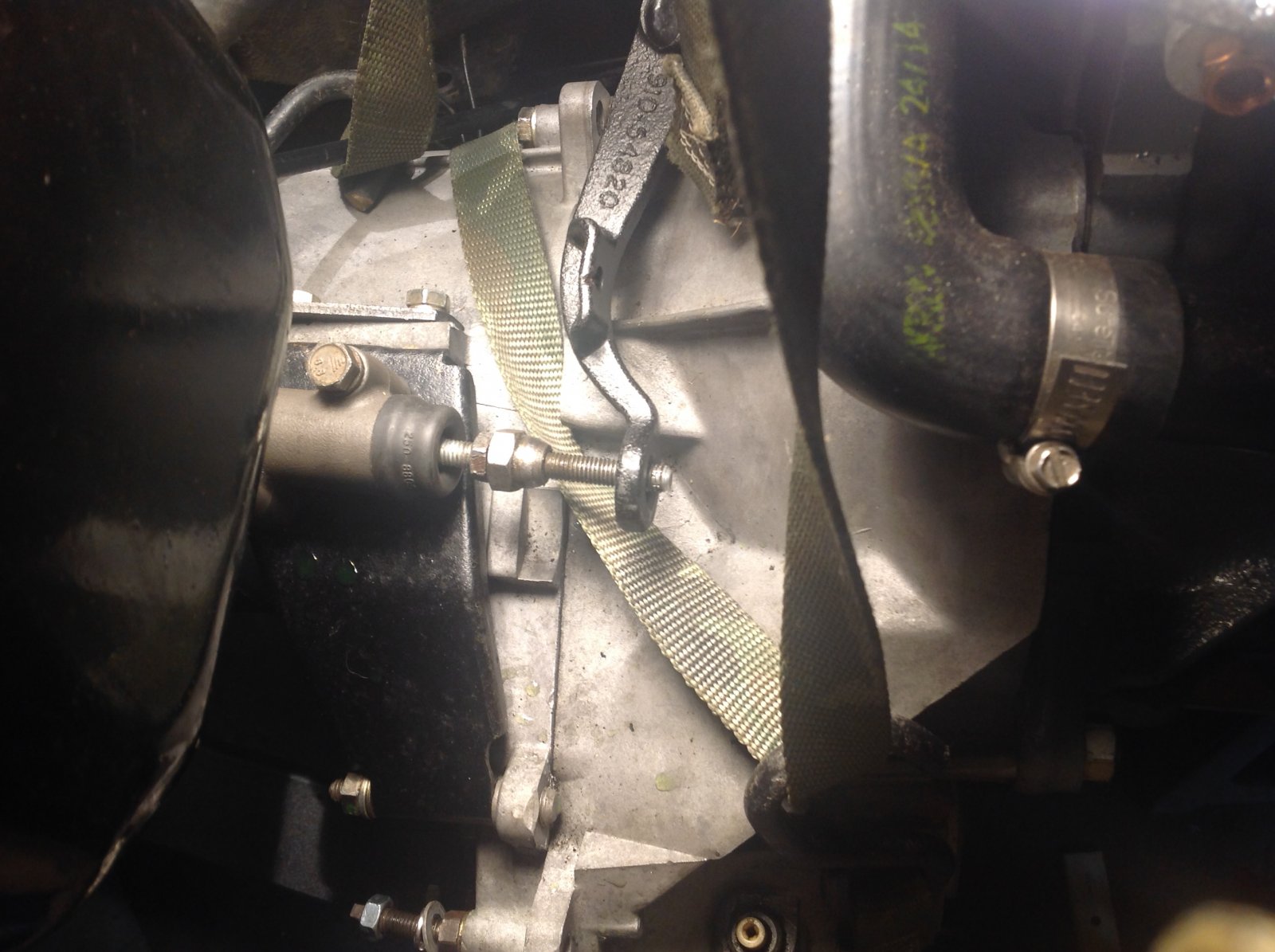

My 74 has a 1980 1500 engine with my original 74 four speed. Note that the clutch lever is at the extreme of its travel before the clutch will disengage. Pay no attention to where the stop screw is - I moved it to show where the arm first contacts the plate. I should add that I installed a lightened flywheel from MWB marked "75 - 78 but this problem was there when I first did this conversion long ago with the original 1300 flywheel. This arrangement does work but was not like this when the car was new with the 1300 block and flywheel. Is there something about the 1500 block different than the 1300 that would cause this ? I did trial fit the tall pressure plate just to see what would happen but it bound up on the 1300 bellhousing proving that I have the late 1300 bellhousing. As far as I know there are only two types of pressure plates for the X. The pic shows how far the clutch arm has to travel before the release bearing contacts the fingers on the pressure plate. Has anyone done this conversion and noted this characteristic ? As long as it works should I not worry about it ? Thanks in advance . . .