jovani

True Classic

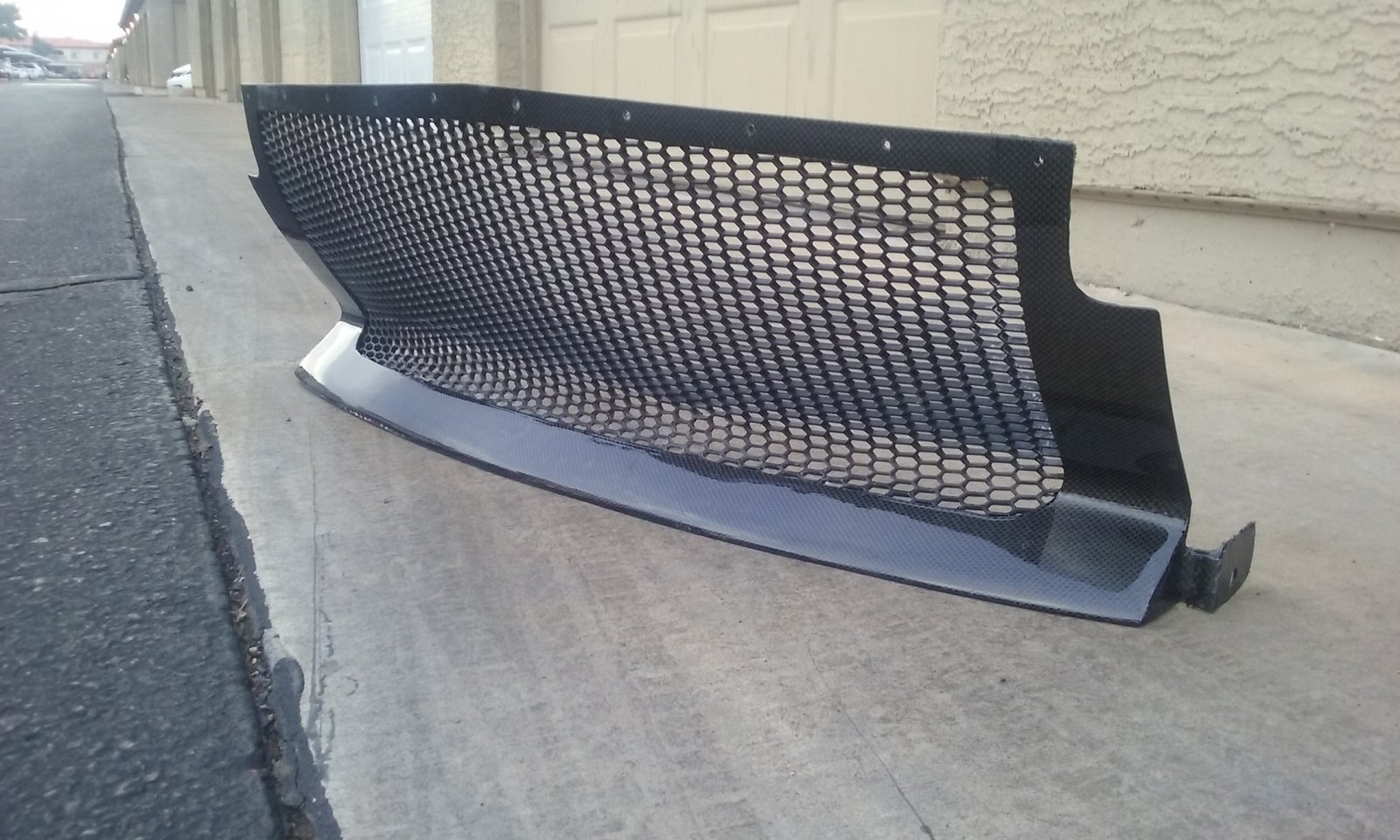

I have mentioned this before, but sharing experience after 6000 miles. Bought VA aluminium radiator, flipped it upside down and tilted it backwards about 35 degrees (bottom aligned with valance and top as far back as possible). For that reason: used drain port as bleeder; plugged thermo port with rad supplied big plug; bleeder port is now drain; found 110 degree sharp turn hose for feed side; from old rad I removed the hose brass barbed ends, soldered them together to make male-to-male straight (they end up flattened in the middle by default) and on the flat I drilled a hole and soldered the old rad thermo switch threaded insert. Now I have thermo switch inline the return (bottom) hose, from the middle straight of which I cut a section the length of my new thermo switch assy. Made sheetmetal shroud around top of the rad, It happened to have much less angle behind the rad, about 40 degrees, unlike the original "parachute" shape, 3" less hight too. Mounted two sleek quiet el fans, one operated manually from dash (on demand). Also re-used bottom rad mounting cross member with slight mods. Result is oncoming air goes uninterrupted by turbulence or high air pressure (unlike the original setup) and once "sliced" by the nose and the valance, has nowhere to go but through the rad, exiting with almost no drag if not pulled behind rad and under the car by lower air pressure. BTW, that's the reason I made carbon grill/valance assy with lower cut above the valance.

I drive 22 miles one way every day, half in traffic, half on freeway, and temps in Phoenix are above 100F lately. Coolant stays 180 steady at all times . I had to trick the thermo switch to make sure if it works properly, but so far it never needed to turn on by itself.

I drive 22 miles one way every day, half in traffic, half on freeway, and temps in Phoenix are above 100F lately. Coolant stays 180 steady at all times . I had to trick the thermo switch to make sure if it works properly, but so far it never needed to turn on by itself.